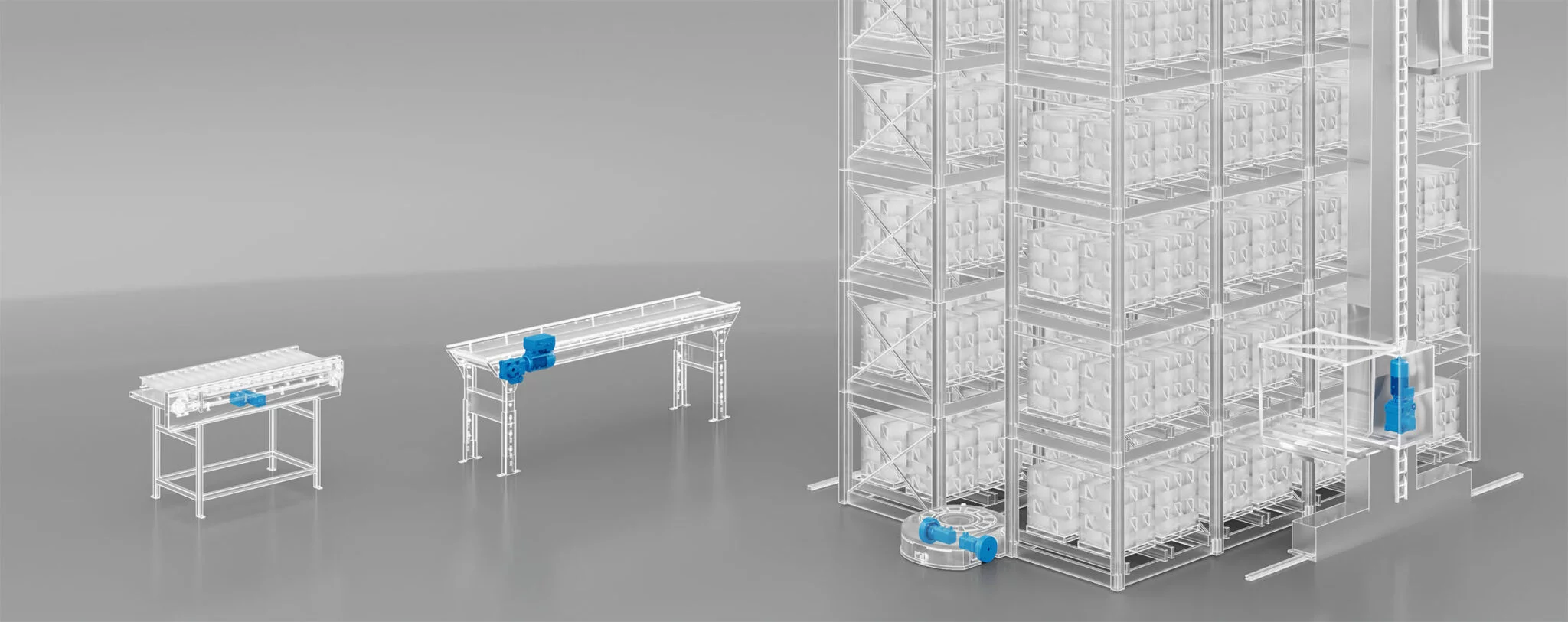

In the pursuit of more efficient, productive and safe operations, a growing number of warehouses are implementing automated guided vehicles (AGVs).

“Companies continue to invest in automation, and in many cases AGVs present the most feasible investment, resolving a number of business challenge, such as labour shortages, worker safety, the need for a flexible factory layout, space saving as well as meeting the demands for more productive and efficient operations,” says Martin Broglia, MD of Bonfiglioli Australia and New Zealand. “As the AGV sector matures, we’re seeing a trend towards solutions that are customisable, modular and deliver precision and high performance. To meet this need, Bonfiglioli has developed the specialised BlueRoll gearbox”.

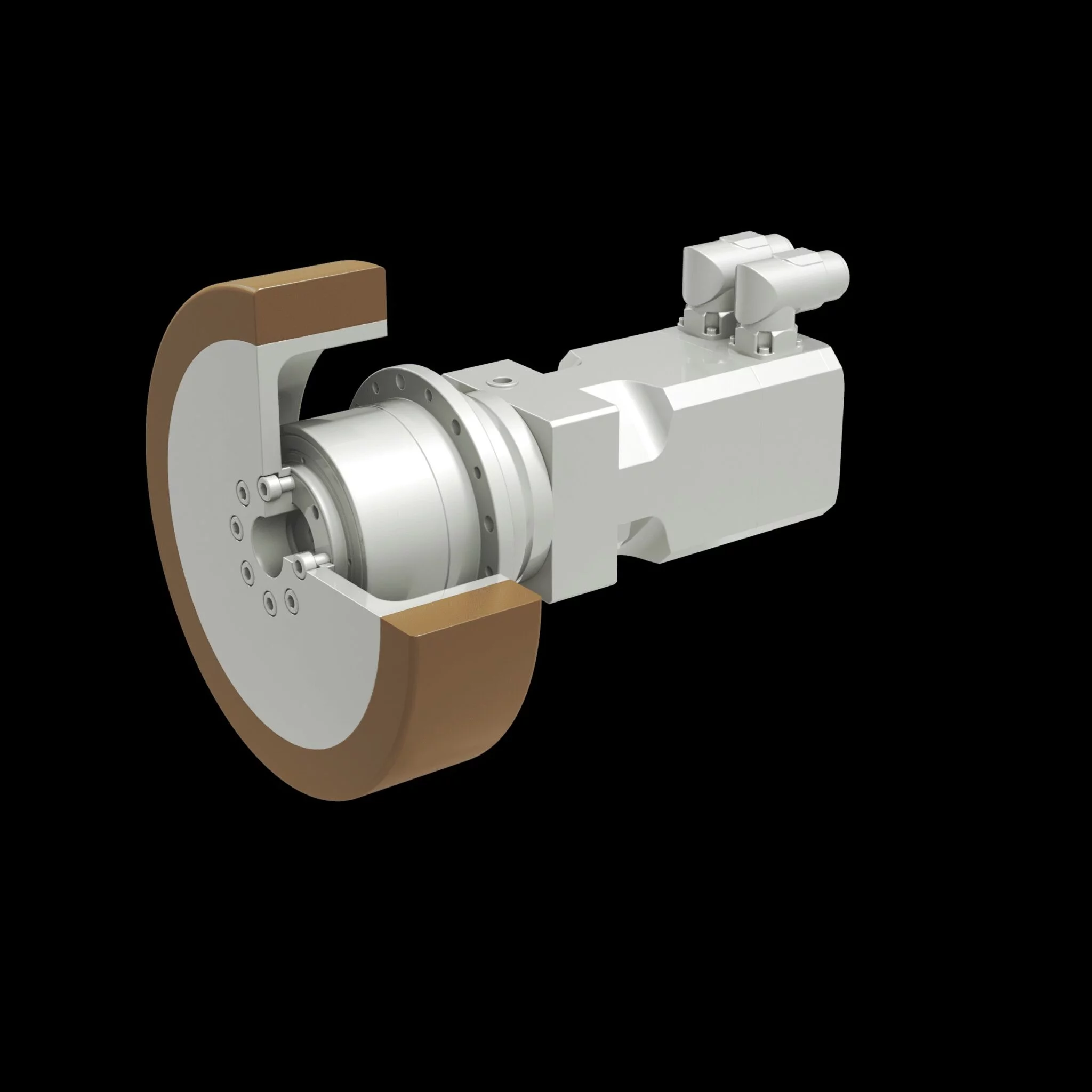

The BlueRoll is a wheel-mounted gearbox, specifically developed to meet the requirements of the AGV sector, delivering excellent position accuracy and high energy efficiency for long operating cycles. This gearbox is almost completely enclosed by the wheel and can be fitted directly to the chassis of the vehicle, making installation easy. The integrated wheel is supported directly by reinforced gearbox bearings, which permit ultra-high radial forces. It’s available in various sizes to meet load requirements, and reaches a speed of up to 2 m/s. With its compact axles and flat design, the BlueRoll is a space-saving solution.

“This is a gearbox that is built to handle heavy loads. It’s also a durable solution, using high-quality precision planetary gears. It comes with a range of feedback systems including safety encoders,” says Broglia (pictured). “It’s ideal for use in a wide range of warehousing and materials handling applications.”

The BlueRoll is currently available in three models:

1. BlueRoll BASIC: Achieves max speed of up to 2m/s, it can handle loads from 360 – 1020 kg. It’s available in three sizes – the 1.7kg TQW 060; the 5.5 kg TQW 070 or 10.9 kg TQW 090.

2. BlueRoll ADVANCED: Delivers low inertia and features a holding and safety brake. Available in three gearbox sizes – with four motor frame options, and a wide range of encoders for easy system integration. The ADVANCED is available in a range of sizes, from the 1.3 kg BMD 65, right up to the 7.7. kg BMD 118.

3. BlueRoll COMPACT: It’s 25% more compact than a standard motor-gearbox solution and is highly customisable. It also offers high energy efficiency thanks to its optimised mechanical design.

“Selecting the right gearmotor is critical. Our technical team ensure extensive consultation and collaboration with the customer, to deliver the solution that meets application requirements,” says Broglia.

Making its local debut

The BlueRoll will make its local debut at the 2025 Foodtech Packtech & MHL expo (taking place from 2-4 September 2025 at the Auckland Showgrounds, with free registration). Bonfiglioli will be exhibiting a number of innovations for the food processing and packaging sector. “The BlueRoll has a lot to offer the AGV brands and we can’t wait to introduce our customers to this smart product,” concludes Broglia.