Glencar, a UK construction company that was recently ranked amongst Europe’s fastest growing businesses, has today announced that it has completed construction of the final warehouse of 771,000 sq ft for leading pan-European and industrial development company Baytree Logistics Developments and its customer global logistics provider Rhenus Warehousing Solutions UK at its new 64-acre, 1 million sq ft logistics campus at a site in Nuneaton in the West Midlands.

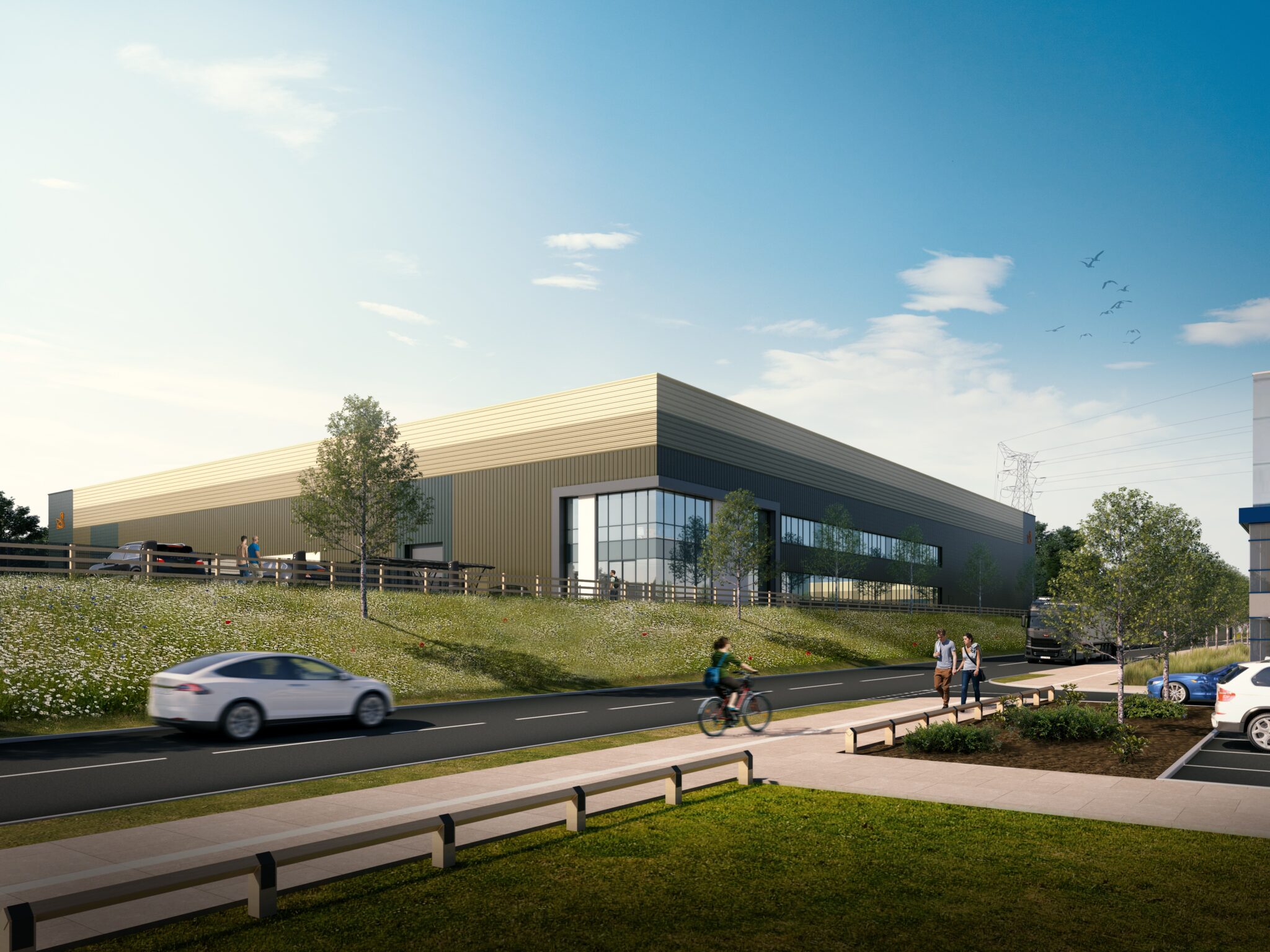

Baytree Nuneaton, known as the ‘Rhenus Campus’, comprises of two warehouses of 210,000 and 771,00 sq ft on 64 acres and sets new benchmarks in environmental and social responsibility within the logistics sector.

The scheme, developed by Baytree, was designed by award winning architectural practice Chetwoods and has been developed to achieve significant reductions in whole life carbon, designed with reference to the UK Green Building Council (UKGBC) Framework Definition for Net Zero Carbon Buildings, ensuring that Rhenus can reduce their own carbon emissions but also potentially support its customers with reducing theirs. Renewable energy will be generated on-site, with solar panels.

Included on the site is a three-storey 30,000 sq ft office headquarters with a structure constructed entirely from CLT and Glulam. This is pioneering because it’s one of the first cases in the UK of timber being used in the build of a large-scale structure within an industrial and logistics setting by a logistics developer.

When compared to conventional materials, procuring timber structural elements can deliver significant embodied carbon savings, especially as timber also sequesters carbon in its creation. The value of timber is demonstrated by the estimate that there are around 1,000 metric tons of sequestered carbon in the timber frame of the office at Nuneaton – the equivalent of enough embodied carbon to power a 20w lightbulb for 21,853 years or to drive around the world approximately 208 times.

The development also incorporates MUGA sports pitches, allotments, edible planting, wildflower grasslands, extensive networks of footpaths to encourage cardiovascular exercise and external break out areas for staff wellbeing. The site, which is bounded by the Coventry Canal, features landscaping with extensive native tree planting, and other works aimed at generating biodiversity such as log piles, locations for apiaries, bat and bird boxes, as well as an extensive balancing pond overlooked by a projecting terrace for staff relaxation.

Internally the facilities will benefit from the latest in robotics, AI and warehouse management systems to provide flexible solutions and control of the supply chain. When fully operational, the development will help Rhenus Warehousing Solutions UK achieve its goals of reducing direct carbon emissions. Both state-of-the-art, sustainable warehouses will offer a wide range of warehousing and distribution services to a diverse customer base of Global retail brands, particularly those in the fashion, toy, FMCG, home and health & beauty sectors.

Commenting on the project Glencar CEO Eddie McGillycuddy said: “It is with a tremendous sense of pride and happiness that we today can formally announce practical completion has been reached and we are handing over this truly incredible new dedicated logistics campus to Baytree and Rhenus. This cutting-edge project is one of the largest and most sustainable developments Glencar has ever had the privilege of delivering and we are absolutely delighted with the outcome. The vast scale of the warehouses coupled with the latest emerging warehousing and logistics technology and innovations looks set to ensure Rhenus can accommodate customers well into the future. As a BREEAM Outstanding certified building we are enormously proud of the hard work and dedication that the team has put in to achieve this outstanding success. I would like to thank everyone involved and look forward to seeing the building come into life and enable Rhenus to meet growing demand and exceed its customers’ expectations.”

Also commenting, Amit Babbar, Baytree Development Director said: “We are delighted to have reached practical completion on this industry leading development for Rhenus. The development incorporates a number of industry firsts on a development of this scale and represents our commitment to pioneering advancements in both the environmental and social elements of industrial and logistics buildings. We are extremely pleased with the collaborative approach taken by all involved to create a new benchmark in the sector.”

Harry Wheelhouse, Business Development & Marketing Director at Rhenus Warehousing Solutions UK added: “This new site will allow us to meet the demands of our growing business and attract new customers, whilst enabling us to deliver our high-quality, personalised service. More importantly, our new, sustainable warehouses can potentially support our customers in achieving their own carbon-reduction goals. Every aspect of our warehouse environment, will be measured using the latest in digital technology including CO2 levels by area. As all companies will need a plan to achieve a carbon-zero supply chain by 2050, Rhenus Warehousing Solutions UK is perfectly positioned to help its customers document their own roadmap to deliver this.”