To help maximise space in the entire cube of the warehouse, vertical storage is extremely desirable. This is an area where Italian manufacturer Modula excels, as Peter MacLeod finds out.

In a traditional stores area in a typical factory where picking of small parts takes place at ground level by operatives walking up and down the pick faces, look up to the eaves and there’s likely to be plenty of unused space that can be potentially converted to storage. This air space is the primary area of focus for Modula, an Italian company that specialises in vertical storage lifts for the manufacturing and warehousing sectors.

Modula was founded in 1987 by Franco Stefani, the boss of System Ceramics, a successful manufacturer of machines for the ceramics industry. In order to boost manufacturing efficiency, he devised a new way to store spare parts rather than using traditional shelving. Drawing inspiration from existing rotating warehouse technology which used operators to rapidly and ergonomically pick up and drop off the required items, he set about designing what became the first Modula vertical lift. Initially deployed in-house at System’s Fiorano Modenese facility, word soon spread across the ceramics industry of Stefani’s devices, and they became widely adopted by the sector. Their use attracted the attention of the wider manufacturing hinterland, particularly in the Emilia Romagna region, and since 2000 a Modula sales network has been established and expanded to service growing demands.

Ever-Greater Efficiency

Whilst the fundamentals of the Modula system remain true to the original design, many variations have been developed, and refinements introduced to meet today’s needs. I recently caught up with John Farren, Sales Manager of Modula UK, to ask him about the company, its products, and the part they can play in helping manufacturers and warehouse operators achieve ever-greater levels of efficiency.

It wasn’t until 2016 that Modula Storage Solution Limited was established in the UK. At that time, they had sold 1,500 machines worldwide, a number which reached over 4,000 in 2023. “The growth has been spectacular,” Farren tells me. “We opened a plant in China in 2019 for the Asian market, and we have two facilities in the States, primarily for the US market, so we now have three manufacturing areas: China, Italy and the USA. We have several Modula companies throughout Europe and the world, and we cover pretty much anywhere else globally through a dealership network.”

Farren describes Modula’s core product as a vertical lift module (VLM) designed to efficiently store – and offer fast and easy access to – a broad selection of products, “ranging from things like nuts and bolts, tooling, raw materials all the way up to pallets of products… and most things in between. We provide a wide variety of systems in this market, with Modulas with trays only 1,300mm wide, going up to 4.1 metres wide, and machines to suit any application in any area where there is a need to store goods.”

Growth Drivers

A key driver of growth in the market has been the need to optimise expensive factory floorspace. Standard racking and shelving takes up an area that could be better turned over to profit-generating activities such as assembly, and Modula showed it can rapidly to changing customer needs. “We brought out the Modula Slim a few years ago to fit into areas that are relatively small and that a standard VLM system won’t actually fit into. That has taken off very, very well. A lot of customers like the idea of having a small, automated storage system at point of use on a production factory floor, rather than having it in a store, where they can keep things like tooling that’s used at that particular location in the factory.”

In a marketplace where – let’s be honest – a customer’s viewpoint is very often that a VLM from in operational capability and design to one from Manufacturer B – they all store at the same incremental heights and will all potentially have similar features – Farren says Modula’s USP is its levels of service:

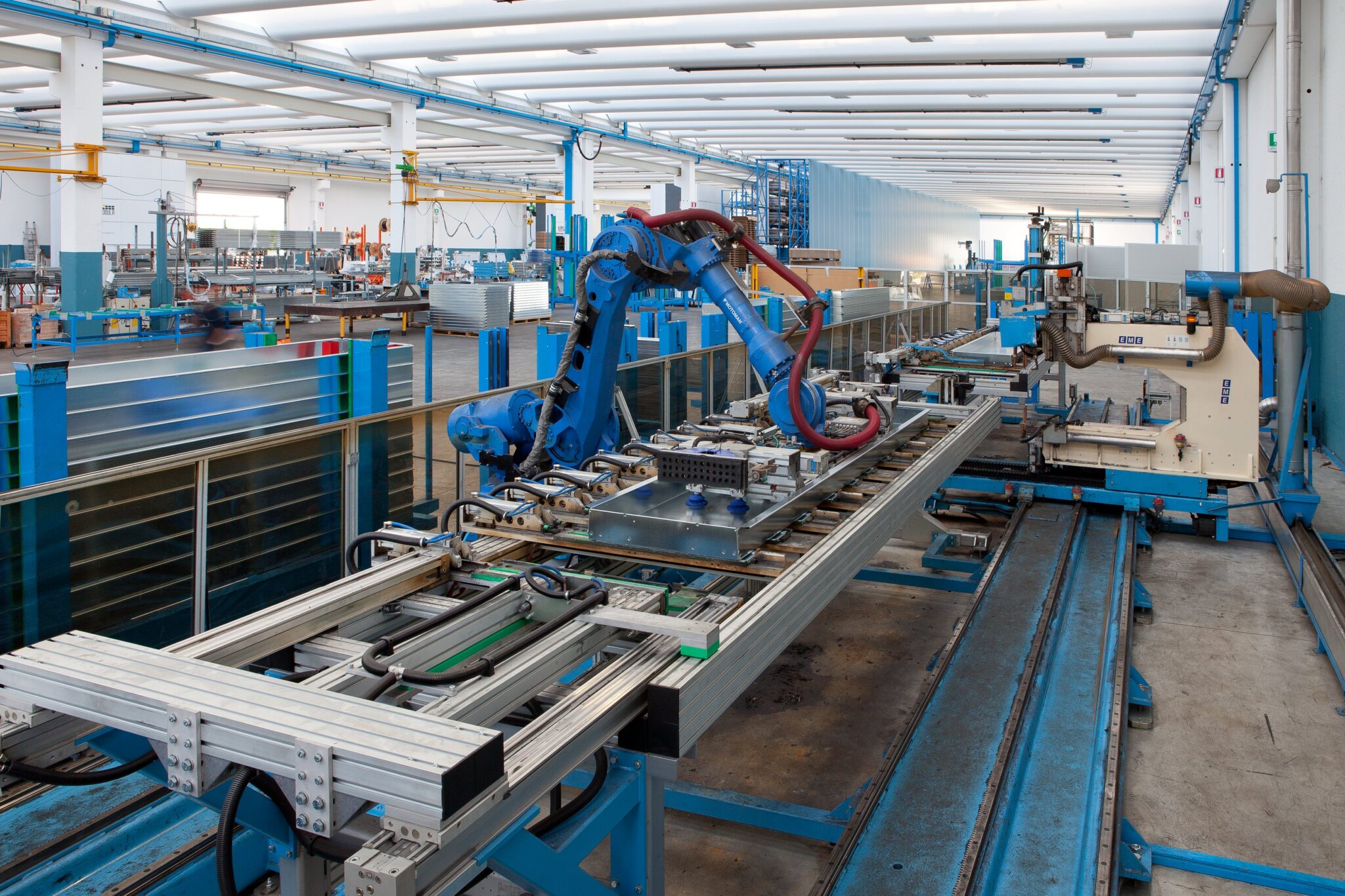

“I’ve been in this industry for almost 25 years now, 15 with another company, and I do think that Modula is very, very good, service-wise. USPs are difficult because as far as customers are concerned, it’s an automated, big steel storage box – ultimately, there’s not an awful lot to differentiate between one machine or another. So you’ve got to look outside the box itself for USPs, and a lot of it is how we partner with our customers. Rather than just sell them a product, we work with them to find a solution. That often involves integration with existing ERP systems, or other forms of automation, e.g. AGVs or anthropomorphic robot arms. I know this is the sort of sales spiel that you get all the time, but we do believe it! We integrate with their existing systems, we work to make sure that the integration goes smoothly, so that they get a solution that actually gives them more than just storage. We work to give them advantages in their marketplace – faster, more accurate picking – that make a difference. If you make mistakes when picking items, it can have a knock-on effect to a production line causing down time or to their customers if they don’t send the right product out. Our solutions also save a lot of labour time, because people can pick far more efficiently from Modula systems than they can from standard shelving and racking.”

Unique Systems

Pushed further in the question of USPs, Farren tells me about some of the solutions he says are unique to Modula. Rather than just small features of the standard Modula VLM, Modula has developed machines specifically designed to be used in areas and applications where a standard VLM doesn’t suit, such as a climate controlled VLM, which is ideal for pharmaceutical, electronic and some retail applications. In fact, any area where there is a need to manage the climate in which goods are stored. “We also have a machine which is designed to be used in cleanroom environments. This type of innovation gives us some advantage over the competitors, in that we supply a product that can suit some of the applications that maybe others couldn’t normally fulfill.”

Unsurprisingly, eCommerce is driving an increasingly growing proportion of Modula’s VLM sales, but high-street retailers are also starting to see the benefits in having a VLM storage system, whether for storing click-and-collect items or dry goods ordered by customers online. “Rather than having pickers walking up and down aisles in a supermarket, getting in the customers’ way, they can have a storage system in the back-of-store area and do a lot of the picking from that. But our biggest growth is coming from eCommerce, where people need to pick items, to package them, and to get them out the door very quickly. They can do that with greater efficiency, and far more accurately using a vertical storage system, and very often with less picking staff. An operator, working between a group of Modulas where items are brought straight down into the access opening, can quickly pick the component from each access opening. They scan a barcode to confirm it’s the correct item, then get it sent to be packaged and on its way to the customer. We’re saving 60-70% of the picker’s time, because they’re not having to walk up and down aisles of shelving to the item location. Goods are brought to the operator where they can be picked ergonomically at the correct height, without the need to bend or stretch to reach items on the higher or lower shelves.

Improving Margins

“Margins in eCommerce activities are often wafer-thin, so if they can reduce the number of people required to do the picking, then that helps improve their margins, and helps make them more competitive in the marketplace. And they also free up an awful lot of footprint so they don’t need as much warehouse area. If they need to bring in pickers on short-term contracts for peak periods, the beauty of our systems is somebody can be up-and-running and using it in 30 minutes. It’s not complicated, it’s very intuitive. There’s a lot of help for the users within the system – for example alphanumeric displays and laser pointers that point to the correct item and display the quantity to be picked – so it’s very difficult for an operator to make a mistake.”

With Sig. Stefani still at the helm as president today, Modula’s growth continues unabated. Finally, I ask Farren about security of stock – a big consideration in warehouses where high-value items stored on open shelving can sometimes find their way into the pocket of a passing visitor. “In a vertical storage system such as ours, it’s not an open store. You have to identify who you are before going on to the system to pick an item. That way, if you don’t have the correct identity, you don’t get access to the system. It means that stock is a lot more secure within a Modula system or a VLN-type system, and it is also far more accurate. Not only is it not open to prying fingers, but it means people can’t just take things from a shelf and not book it out.”

similar news