Mobile robot manufacturers need to take a range of factors into consideration when selecting planetary gearboxes, writes Mike Gulliford, Managing Director, Apex Dynamics UK. The global mobile robots market is expanding rapidly and forecasts for mobile robot revenues were recently increased as a result. With such a wealth of opportunities in the market for autonomous mobile robots (AMRs) and autonomous guided vehicles (AGVs), manufacturers providing products that meet customers’ needs will see sales grow.

Strong outlook for mobile robots and planetary gearboxes

Precision gears are an essential component within the motion control systems of mobile robots, and planetary gearboxes will continue to play a significant role in the market going forward. Just under 50% of precision gear products sold in 2022 had a planetary design, according to market intelligence specialist Interact Analysis, demonstrating the enduring popularity of planetary gearboxes. In fact, mobile robots are predicted to become the #1 industry for planetary gear products by 2026, as high levels of demand continue within the mobile robot industry, driven by labour shortages and increased demand for warehouse automation in the wake of the Covid-19 e-commerce boom.

Planetary gearboxes are ideal for mobile robots

Planetary gearboxes are the ideal compact high-precision servomotor solution for mobile robots, with estimates showing that the vast majority of mobile robots employing precision gear products will have planetary gears (~95%) by 2026. It is of paramount importance that mobile robot manufacturers select the best precision planetary gearboxes for the specific needs of their robots and applications.

Here are seven key factors to consider when using planetary gearboxes in mobile robots, in order to ensure optimal performance, reliability and efficiency:

1. Torque and Power Requirements

Torque and power requirements are specific to the intended applications and payloads. Manufacturers must carefully address the torque demands of each robot’s motors and actuators in order to select planetary gearboxes that can handle loads effectively. Ensuring adequate torque ratings for planetary gearboxes can help to prevent premature wear, overheating and potential system failure.

2. Efficiency and Gear Ratios

A crucial element of mobile robot design, planetary gearboxes generally offer higher efficiency than other types of gearboxes. Manufacturers should carefully evaluate the efficiency of gearboxes and consider the gear ratios that suit each mobile robot’s operational needs. The selection of proper gear ratios ensures optimal motor speed and torque output, which translates into better energy utilization and enhances overall performance.

3. Size and Weight Constraints

Compact autonomous systems such as mobile robots often have limited space and weight allowances. Planetary gearboxes are known for their compact and lightweight designs, making them the preferred choice for many manufacturers. Manufacturers must give consideration to selecting gearboxes that fit within the space constraints and adhere to the weight limitations of their mobile robots without compromising performance.

4. Backlash and Precision

Precision gearboxes are designed to have low or zero backlash, meaning the clearance between interlocking teeth is much smaller than in standard gearboxes. This improves the accuracy and repeatability of robot movements, which is particularly important in applications where fast, precise movement is required, such as industrial automation or medical robots. Choosing planetary gearboxes with minimal backlash helps to maintain positional accuracy and reduce errors.

5. Lubrication and Maintenance

Choosing the correct type of lubrication and understanding the maintenance needs of planetary gearboxes is vital to ensure the smooth and efficient operation of mobile robots. For example, sealed gearboxes or those with extended intervals between lubrication may be preferred by mobile robot manufacturers in order to reduce maintenance requirements and extend system uptime.

6. Durability and Reliability

These factors are key to the overall longevity of mobile robot systems, with some robotic applications operating in or exploring harsh environments, or carrying out heavy-duty material handling tasks. Mobile robots operate in a range of environmental conditions, including extreme temperatures, and environments heavy on moisture and/or dust, with some even designed to operate in underwater environments.

Intense operating conditions make it crucial for mobile robot manufacturers to select gearboxes that are made from high-quality materials and that are precision manufactured to ensure they can withstand the rigours of the application, with adequate protection against corrosion, ingress and environmental contaminants. For example, all Apex Dynamics UK gearboxes are made in our CE and ATEX-certified manufacturing facility and come with a 5-year warranty.

7. Cost and Availability

A further consideration for mobile robot manufacturers is the cost of the gearboxes they are selecting for their mobile robots and their availability on the market. It is important to strike the correct balance between required performance and budget constraints to ensure the project (and product) remains economically viable. Furthermore, good delivery times for planetary gearboxes are crucial to ensure products are ready to ship to customers. At Apex Dynamics UK, we guarantee delivery within 3-4 weeks, combining high quality products with reasonable prices, excellent customer service and support.

With an array of possibilities to choose from when it comes to planetary gearboxes, there is the potential to find the right fit for each mobile robot and its potential applications. By considering the variables above, manufacturers can make informed decisions and help to ensure they develop robust, best-in-class products, with high performance, low backlash, precision, durability, minimal downtime, and success in their respective applications.

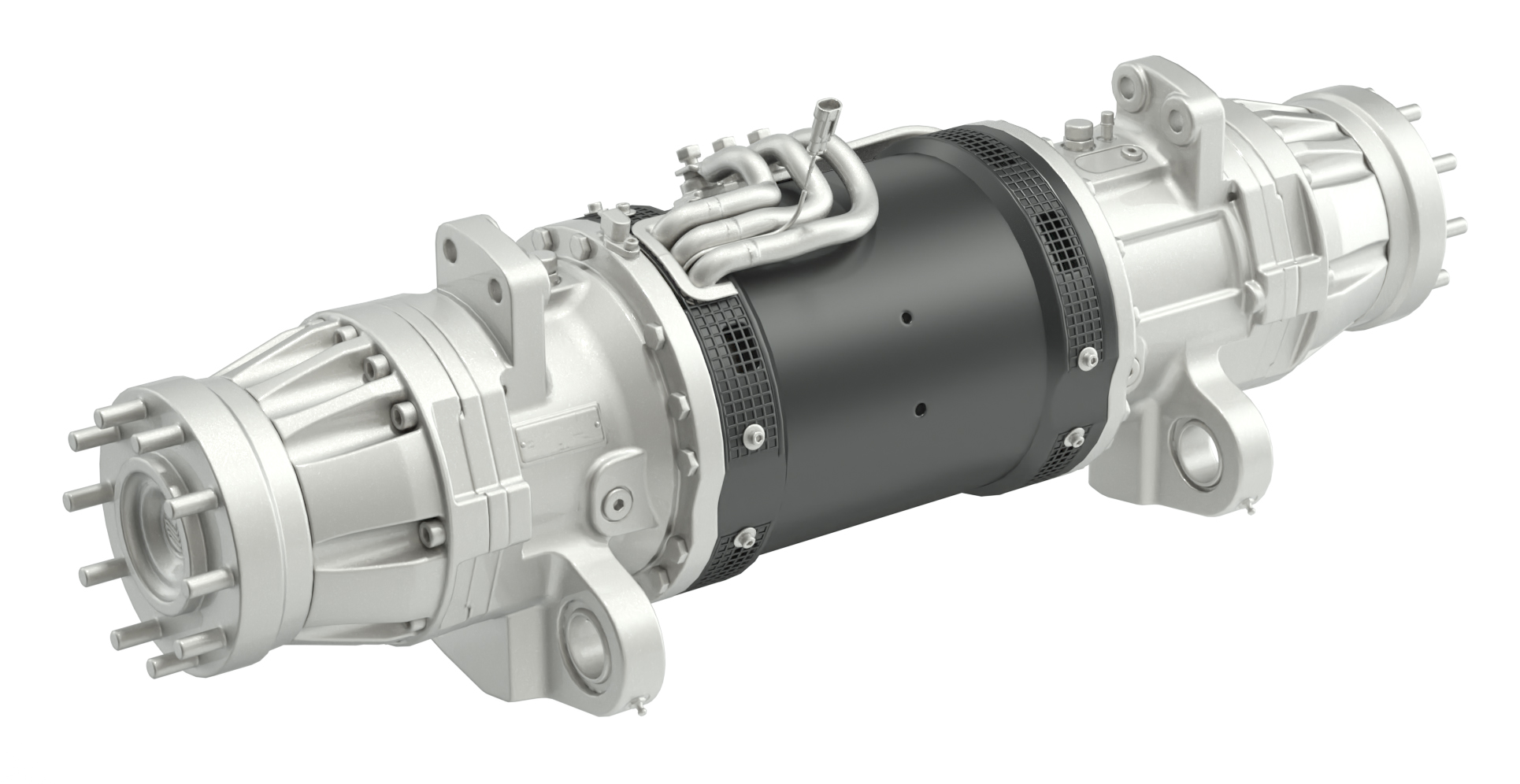

At Apex Dynamics UK, we supply products to the mobile robot industry and our new GL series of precision planetary gearboxes has been specifically designed for AGV applications. With a unique rotary housing that allows a drive wheel and pulley to be mounted over the exterior, Apex Dynamics’ GL helical planetary gearboxes are available with a shaft input (GLS), which allows the gearbox to be driven by belt and pulley. GL gearboxes are fitted with helical planetary gears hardened to 840 HV, patented input and output sealing, and a patented input bearing system that ensures perfect concentricity, making them the ideal choice for mobile robots.