Ferag, a global leader in advanced conveying and sortation solutions, has launched its hi-tech, Swiss engineered overhead pouch and sorter systems to the UK market. The technology offers retail, ecommerce, automotive and general merchandise businesses reliable, high-performance conveying and sortation at speeds of up to 12,000 units per hour.

Based in Zurich, Ferag has its origins in the international print industry, where ultra-reliable, high-speed conveying technology is essential to the time-critical production of newspapers with daily print runs in the millions. With over 60 years’ experience designing, engineering and fabricating, high-speed overhead conveyor systems for mission-critical interlogistics operations, Ferag has now secured a strong presence in the UK intralogistics market by winning three new contracts for solutions in the apparel and retail sectors.

Heading up Ferag’s UK operations, Darcy de Thierry, Managing Director, Ferag UK Ltd, says: “British retailers and manufacturers are experiencing huge structural change. The growing focus for most is on ecommerce orders, which places a heavy emphasis on high-performance fulfilment operations capable of handling thousands upon thousands of single or few-item orders a day.

“Automated systems, such as overhead pouch and sortation solutions, facilitate fast picking, making them increasingly critical to maintaining and growing order volumes. But businesses cannot afford for them to fail – they need well engineered solutions using only the best, hard-wearing components and low-friction materials. That’s where Ferag’s extensive experience within the newspaper industry – where reliability is paramount – will be a tremendous advantage to the UK market.”

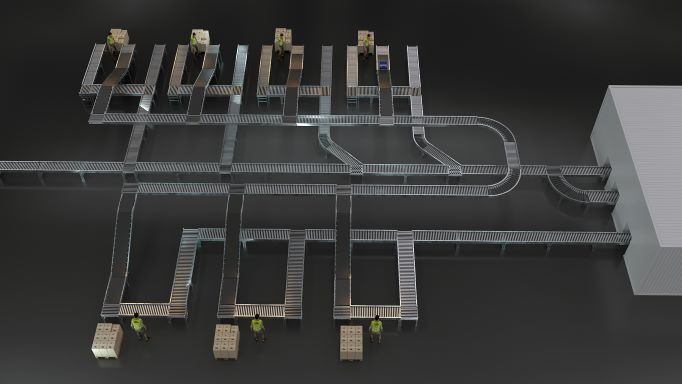

Principle products in Ferag’s extensive range of innovative sorters and conveyors include: Skyfall, an overhead pouch system that combines conveying, buffering, sorting and consolidating, suited to a wide variety of goods weighing up to 20kg. The solution makes efficient use of available overhead space; Denisort, a tilt-tray sorter that provides order picking, conveying and sorting in one seamless and scalable solution; Denisort Compact, a modular vertical sorter designed for items weighing up to 12kg; Deniway, a plate chain conveyor with low-friction rollers for long conveying distances, offering smooth transfers with the minimum number of drive units; and Easychain, a largely maintenance-free continuous and seamless conveying system with an ultra-narrow curve radii, making it well suited to complex, 3D layouts.

Ferag has installed intelligent conveyor and sortation systems for some of the world’s largest brands, such as: DHL, Auchan, Nestle, Zeiss, Cewe, Zalando, Mayoral, Viapost, Peerless Clothing International, Dumoulin, AstraZeneca, Stage, VW, Shoebox, along with many more.

The launch into the UK’s intralogistics market plays to the strengths of Ferag’s international maintenance and support network, where remote and condition monitoring are provided 24/7 and replacement components are readily available to a UK based nationwide team of service engineers.

Ferag AG employs around 550 people worldwide and is represented in more than 18 countries with its own sales and service companies. The business has installed over 3,000 systems on five continents and holds in excess of 9,000 registered patents.