Ensuring your logistics operation is future-proofed is harder than ever, with the pandemic has drastically changing consumer behaviour. It has sped up what was already an upward trajectory for the adoption of online purchasing and digitalisation. In order to thrive, businesses need to ensure continuity of supply, the ability to implement remote staffing and social distancing and an agile supply chain with the capacity to meet increasing consumer demands. The change in consumer behaviour offers many opportunities to businesses. Some advice by robotic and automation solutions provider, CFK, details how you can ensure you are prepared to make the most of these.

The receipt of containerised product presents a challenge for the logistics industry in that it requires a large amount of resource to manually unload the container and palletise it. Not only is this labour intensive it can be a HSE risk due to potentially heavy loads, repetitive work and reaching to build pallets. There are extremely effective solutions in the industry to help reduce the reliance on labour and the HSE risks involved in the whole of this process. Here are some of the technologies that you can integrate to reduce the impact on your business and improve the efficiency of container unloading.

Boom Conveyors for increased throughput and reduced manpower

Boom conveyors come in a range of shapes and sizes but are all based on the same concept, a simple telescopic conveyor which can extend into a container as it is unloaded to reduce the distance walked by your operators and offer a more ergonomic handling environment. Boom conveyors help increase the unloading rate for cases and products by reducing the distance travelled by operators therefore reducing fatigue.

The types of Boom conveyor available are:

Fixed position Telescopic flat belt conveyors – these are ideal for unloading a large range of product sizes as some smaller cases do not handle well on roller conveyors, this version is fixed to the floor in front of a single loading bay and cannot be moved Rail mounted (or mobile)

Telescopic flat belt conveyors – this takes the benefits of the flat belt version but is mounted to rails or onto a substantial mobile base to allow it to be moved from one loading bay to another – this allows you to remove the waiting time of container movements as you can move to a pre-docked and booked in container immediately

Fixed or mobile telescopic roller conveyors – these work in the same way as the flat belt conveyors but utilise roller conveyors

Bendy Boom telescopic conveyors – these conveyors are based on the standard telescopic boom conveyors but have a section of conveyor which can be pivoted to cater for significantly different height vehicles (i.e. Container lorries or smaller panel vans).

Checking System to ensure full traceability

Once the cases or products are unloaded from the container the next critical step is to identify the product and book it into the higher level warehouse management system so that it can be receipted, labelled (if required) and sent to the defined storage destination. This can be an immensely time-consuming task when done manually and can lead to inadvertent human error when performed consistently for long shifts. With the development in scanning and weighing technology there are now inline systems that can perform a number of validation checks on the inbound cases such as…

Five-Sided barcode scanning – using an array of scanners the cases can be scanned on all five exposed sides to detect barcodes fixed at any point or orientation on the cases provided they are visible and in good condition

Case profiling – using laser scanners the cases can be measured precisely to confirm the case dimensions match those associated with the barcode detail, if the case is damaged or incorrect, for the barcode attached, it can be rejected locally without the risk of blocking any downstream equipment ensuring there is no downtime on your line.

Case weighing – the weight of the cases is also a very important factor to check and record in many cases when booking in product, this is another standard element of equipment that can be integrated into the system whilst the cases are in flight.

All of this information can be collated and recorded directly into your warehouse management system, if this is then coupled with an automated palletiser it can be automatically tracked and logged to a specific pallet all without the need for operator intervention.

This equipment has been proven to be highly effective in many of the main e-commerce and high-street brands and is a standard ‘off the shelf’ offering from leading vision companies such as SICK and Cognex.

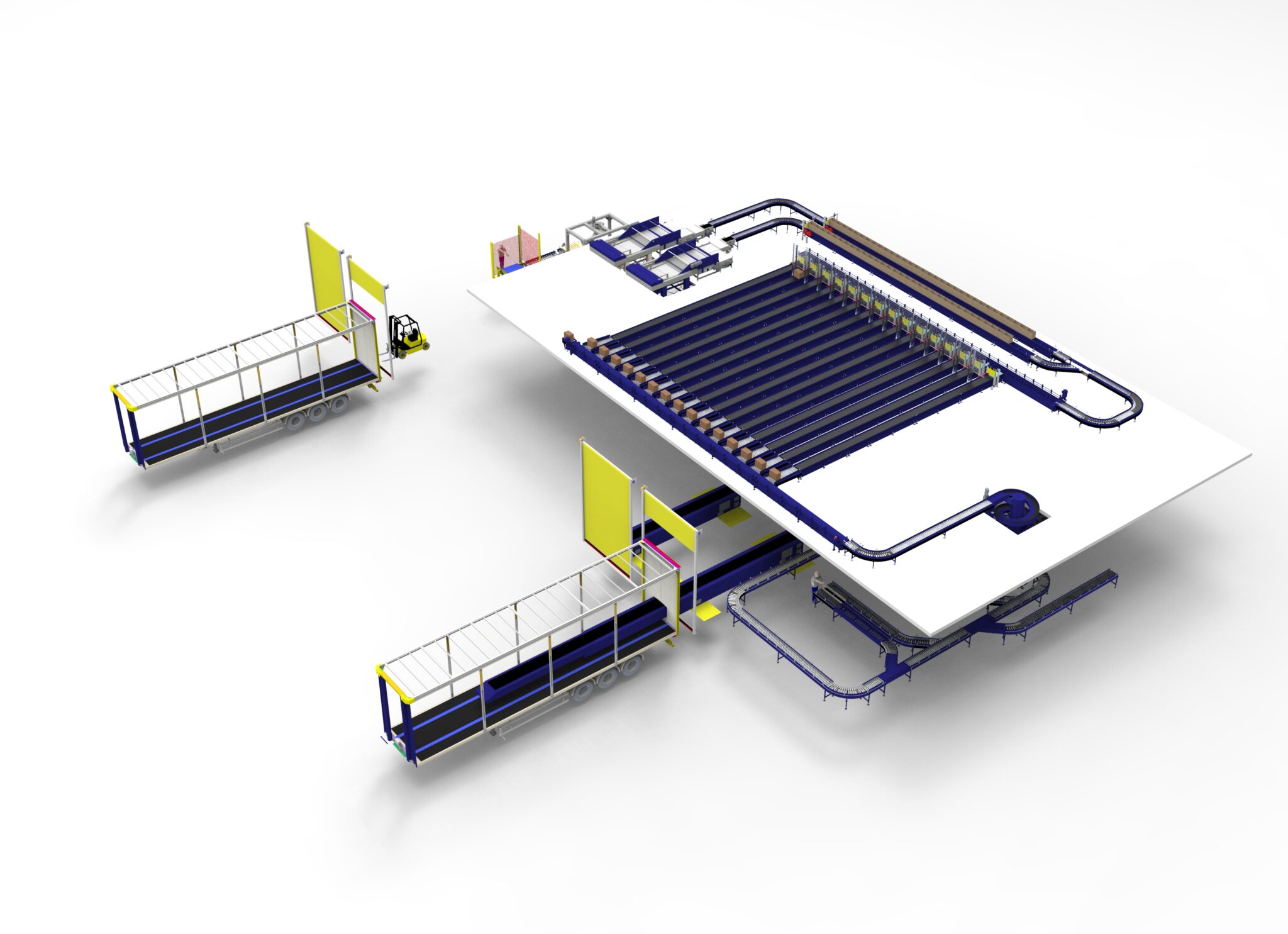

Automated Palletising for a more efficient supply chain

By automating your palletising you’re ensuring a fast flowing and efficient supply chain by speeding up and increasing throughput to meet increased demand, reducing damage and improving safety for your workforce due to reduced manual handling and increased social distancing. An automated palletising system will receive mixed product from a container or multiple containers then quickly sort it into pallets. The palletising system can incorporate a full traceability system which links to the in-line check and enables the user to sort and characterise the end solution by weight and profile as well as using barcodes which enables all products that are loaded onto each pallet to be logged into your warehouse management system. By barcoding each product the system can sort the product into categories. The automated palletising system has the capability to auto wrap and label the pallets as well as offer full traceability.

Automated Guided Vehicles offer increased safety and resilience

Once the product has been palletised it can often need moving across large distances which can be very labour intensive. Automated Guided Vehicles can completely remove the need for operators in high traffic areas. The latest generation of AGVs use natural structures in the environment and don’t need a specific infrastructure or any inductive wires, magnets or reflectors in order to work. They utilise highly automated map building technology and efficient route design to ensure they fit, and can be integrated seamlessly, into an existing plant. The AGV management software can be installed onto the AGV so they don’t need specific fleet management software. Latest generation AGVs are also a cost-effective way of handling large payloads while at the same time allowing organisation to reallocate their staff from the warehouse floor into safer roles. AGVs offer organisations a quick ROI, reduction in costs but also increase resilience by reducing their dependency on manual labour.

Integration of the latest innovation for a fast ROI and a more agile logistics operation

There are many different options to ensure your business is fully prepared for a new purchasing landscape. As a systems integrator CKF do a complete feasibility analysis and then design and develop the full solution for our customers utilising the cutting-edge technology from our partners, OEMs (Original Equipment Manufacturer). We use our extensive knowledge and skilled engineering team to project manage and manufacture the full system and ensure that all elements work optimally in unison to ensure maximum productivity, minimum wastage, reduction of labour cost and better staff utilisation. In collaboration with our partners we offer operators of the new systems training and support to ensure smooth set-up and running of the new system.

Sign-up for our newsletters to keep up-to-date in the logistics sector.