With cost cutting still very much at the top of the business agenda, companies across the world have already started creating improvement plans to tackle operational expenses, writes Simon Thompson (pictured), VP Northern Europe at JAGGAER.

Businesses are focusing on driving value through supplier partnership and are prioritising visibility of stock and procurement strategies optimisation. In fact, one typical business area that is usually seen as no more than a cost centre is procurement and, more specifically, the supply chain. As a result, savvy businesses are reassessing their approach to supplier relationship management, enacting measures that amount to a complete paradigm shift to transform this function in a value centre that can create long-term value as well as reduce costs.

Traditional cost-cutting strategies, that prioritise short-term savings and negotiating the lowest possible prices with suppliers, can backfire over time, potentially leading to quality issues that may escalate into expensive product recalls, customer dissatisfaction, and reputational harm. Strategic partnerships and collaboration within the supply chain can instead become an opportunity to create additional value that goes beyond simply reducing costs, allowing the procurement officer to consolidate spending or uncover shared efficiencies to encompass a range of key issues and benefits such as promoting sustainability, co-investing in innovation and finding new avenues to enhance customer satisfaction. These partnerships can help mitigate supply chain risk, improve resilience, foster digital transformation and facilitate regulatory compliance.

Collaborative procurement strategies

Effective cost management in supply chains therefore extends far beyond reducing raw material costs and covers every stage of the supply chain, from sourcing and logistics to inventory management and payment terms. That’s when collaborative procurement strategies come into play. These strategies are based on building trust and transparency, fostering beneficial partnership with the supplier with the aim of achieving cost saving without compromising quality. Open dialogue and transparency are at the core of this approach, allowing buyers and suppliers to collaborate openly, sharing objectives and creating mutual benefits. Sharing demand forecasts helps suppliers optimise production processes, minimising waste, lowering operational costs and reducing prices.

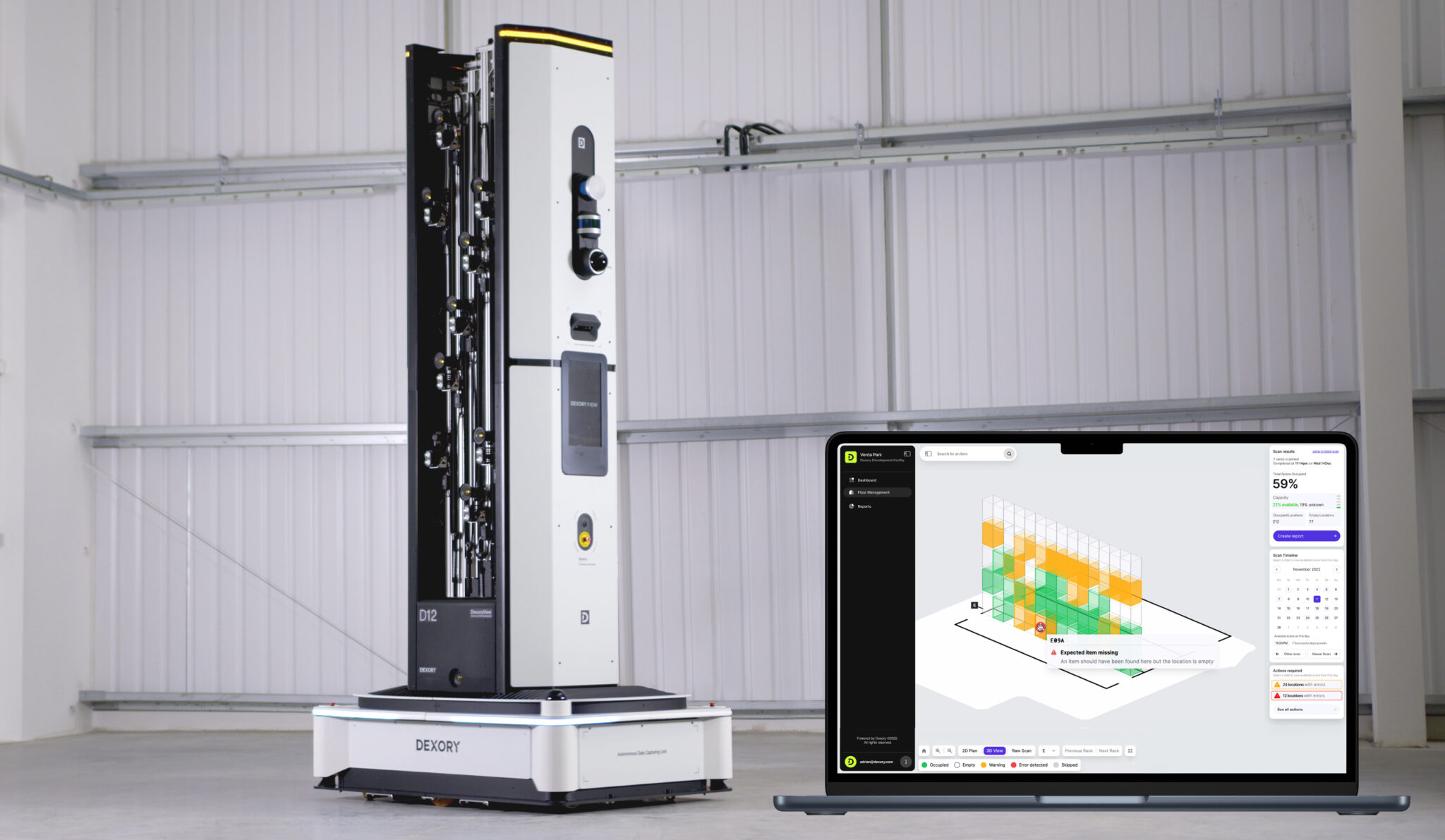

Key to achieving this transparency are real-time procurement platforms that grant visibility to both companies and suppliers and can also improve demand management and inventory needs synchronisation, prevent overproduction, as well as enabling more efficient resources allocation, production schedules and inventory management, ultimately reducing unnecessary costs. While it’s important for procurement to have visibility, trust is a two-way process and a sometimes overlooked component of supplier collaboration is committing to on-time payments. Consistently paying suppliers on time fosters trust, which can lead to improved payment terms or pricing advantages.

Thanks to these platforms it is also possible to enable Just-In-Time (JIT) processes. In fact, partnering with suppliers to implement JIT inventory systems can help minimise excess stock and storage costs, while ensuring timely delivery of goods. This is particularly relevant for industries handling bulky items, perishable goods, or material requiring strict temperature control, such as those managed within the cold chain. In the pharmaceutical sector, for instance, JIT helps reduce waste and improve efficiency by ensuring medicines or devices are ordered and delivered only as needed for production, significantly reducing the likelihood of having to deal with unused or out-of-date stock.

Efficiency gains

Conducting regular supplier relationship evaluations using scorecards provides another avenue for efficiency gains by identifying areas for improvement, uncovering potential cost-saving opportunities, and strengthening collaboration. These evaluations also offer a transparent foundation for discussions and renegotiations with suppliers and offer the opportunity to raise issues or share ideas for improvements such as a new supply route or material. Centralized platforms that automate transactions, facilitate communication, and provide advanced analytics allow businesses to identify inefficiencies and optimize procurement strategies. By leveraging intelligent technologies, companies can enhance decision-making, mitigate risks, and access diverse data sources, without overburdening internal teams or suppliers with excessive manual data entry and updates.

Procurement’s focus is shifting from cost control to driving value creation, and supplier collaboration is emerging as a pivotal strategy for achieving not only sustainable cost savings but also broader operational improvements. Success in this area hinges on building trust, ensuring transparency, and adopting a comprehensive approach that balances cost savings with other factors like quality, supplier diversity, long-term sustainability, and risk management. This approach relies on a strong data foundation across the entire source-to-pay process, supported by advanced spend analytics. With these tools, procurement leaders can develop and implement strategies that deliver significant value for both buyers and suppliers, while nurturing strong, cooperative relationships with every actor of the supply chain.

similar news