Knapp, leading technology partner for value chains, is making its MultiScan master data capture system available to customers through short-term rental or outright purchase.

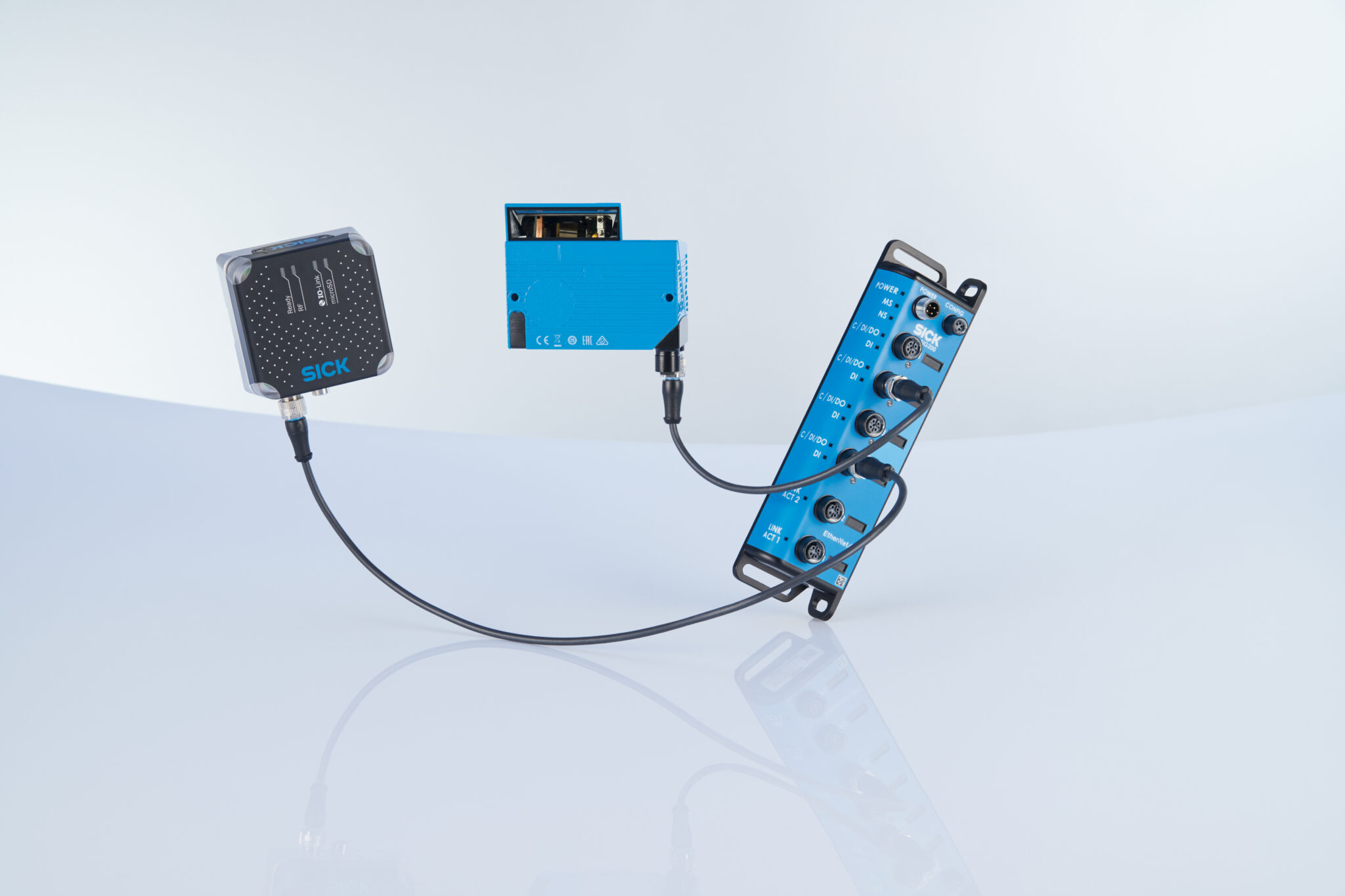

MultiScan is an intelligent and customisable master data capture solution. As well as acquiring article dimensions, MultiScan features integrated weight recording and can also capture other data such as fragility and stackability. The solution records all the data needed to optimise the utilisation of storage space and the efficiency of fulfilment operations.

“The MultiScan system can be particularly beneficial for companies handling seasonal or promotional items of stock,” explained Ben Carroll, IT Business Development Manager for Knapp UK, “as well as for retailers or 3PLs working with multiple vendors, smaller warehouse operators looking to boost efficiency in their e-fulfilment operations or organisations needing to capture article data for robotic systems.”

Maximum efficiency

As well as enhancing manual warehouse operations, capturing accurate master data is essential for automating material flows and achieving maximum efficiency through digitalisation of work processes. MultiScan automatically records all relevant data for an application, transmitting the information to the WMS or ERP system to enable optimal warehouse management. By maximising space utilisation – in totes, on shelves and in racking – and optimising the efficiency of packing operations by fitting more items into each carton or bag, MultiScan enables warehouse operators to achieve environmental benefits and lower transport costs. In addition, improving fulfilment efficiency – by requiring fewer visits to each location and fewer tote retrievals – means shorter picking times for both automated and manual systems, thereby improving the customer experience.

Accurate and versatile

MultiScan is suitable for a wide range of articles and records data with consistent accuracy. Optional precision scales and digital callipers enable measurement of smaller items, starting at 0.01mm and 0.5g. Another accessory, SCANtape, allows wireless measurement and identification of goods sized up to 3m. Further accessories include a bar code scanner and an industrial camera for high-resolution product photos, which can be directly interfaced to merchandising systems. An optional cart and battery mean that MultiScan can be used for mobile operations for up to 16 hours between charging, with the advantage that a 1-hour charge returns the battery to 80% capacity.

Intuitive operation

Featuring intuitive design, MultiScan enables rapid operation and avoids the need for lengthy training. Items can be placed anywhere on the measuring plate and data is captured quickly and automatically at the push of a button. The design is rugged and ergonomic, making it simple to use even when wearing gloves. “The solution’s software is compatible with any end device,” added Ben Carroll, “as well as with various interfaces and all common operating systems. MultiScan is also compatible with KNAPP’s AI-enabled KiSoft Genomix software in order to capture additional attributes and accelerate the process.”