Dematic has recently finalised the delivery and installation of an AutoStore system for Righi Elettroservizi SpA, a leading Italian company in industrial automation, system integration and information technology.

“We have been impressed by Dematic’s global network of industry expertise and its organisational structure, which allows it to efficiently implement the type of high-priority solutions required by our management,” explains Luca Righi, Operation and Supply manager.

The difficulty of material procurement had grown into a global challenge over the last two years, impacting the daily business at Righi Elettroservizi, which determined it needed to develop a quick response to the changed supply chain environment to remain on course with its growth strategy. The company operates nationally and worldwide either directly or through subsidiaries. Thus, its aim was to improve its storage and performance of its production order preparation.

As a response to the ongoing supply chain challenges, Righi Elettroservici targeted expanding its warehouse stock to cope with longer lead times with replenishment seen as a critical component of its strategy. Headquartered in Mercato Saraceno, not far from coastal town Rimini, the company was convinced the Dematic solution would be the best response to the global supply challenges at its site location.

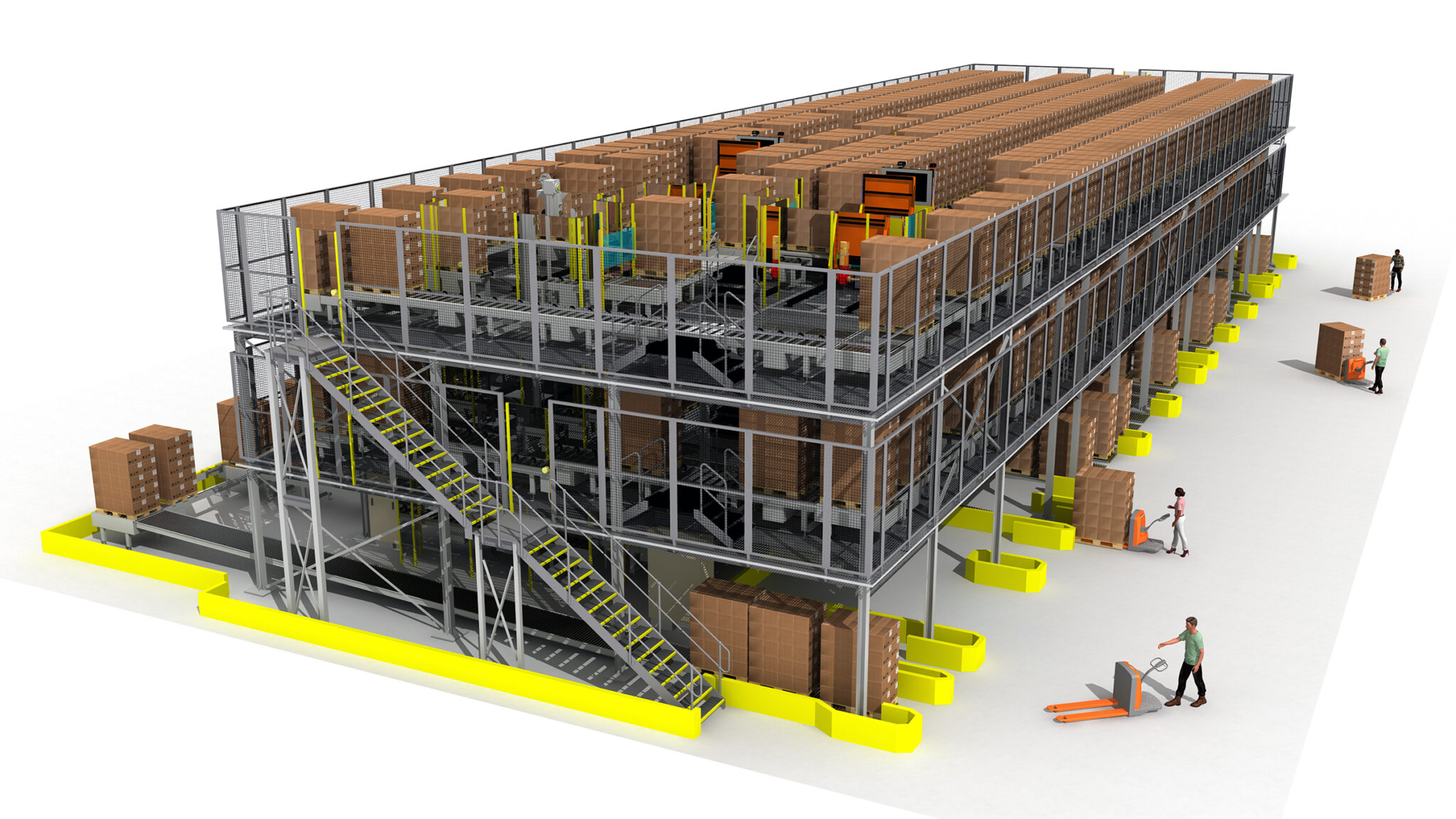

The compact goods-to-person automated storage and retrieval system installed by Dematic, a global leader in the design, installation and support of intelligent automated solutions, requires no additional floor space and facilitates storage of supplemental stock. Installed on an area of 170 square metres (1,830 square feet) the stand-alone system can provide storage for up to 480 cubic metres (5,167 cubic feet) of products. The solution incorporates a 16-level grid with 5,800 bins (330 mm), seven R5 robots and two picking carousel ports as well as a single put-away carousel port.

The automated solution has been integrated into the company’s existing materials storage environment, providing a boost in efficiency, quality and safety. It has also proven to be instrumental in faster and more accurate handling of large quantities of items, which has led to more efficient management of anticipated increases in production volumes.

With the Dematic solution, which took 11 months to complete, the expectation is to accelerate order completion as well as to quickly accommodate customer demands, raising their level of satisfaction. A pick is now completed in 35 seconds, which represents a time savings of nearly 50 percent.

Commissioning of AutoStore

The Dematic solution has also led to marked improvement in material traceability and Righi can more easily pinpoint the path of the material – arrival, storage and exit – within its facility. An added benefit has been the full integration of the Autostore™ system with the company’s previously installed warehouse management system without any new software investment. It has allowed warehouse operators to continue managing the material flow using a system they were already familiar with.

Rosario Filomena, a sales manager with Dematic, comments, “the system provides the benefits the customer anticipated for handling the materials needed for switchboard production, And Righi Elettroservizi, which has been a longtime supplier to Dematic, has become one of our best customers!”

read more

AutoStore Joins Dematic’s Supply Chain Optimisation Portfolio