In the modern age of logistics, the warehouse is no longer a static storage space – it’s a dynamic environment at the heart of the supply chain. Yet, many warehouses today still operate in the dark. These “blind warehouses” lack the visibility, data, and systems needed to react quickly, predict disruptions, or make data-informed decisions.

Limited visibility with Blind warehouses

Blind warehouses are characterised by limited visibility into operations. Inventory counts may be outdated, workflows are manual, and decisions rely on human guesswork or historical trends rather than real-time insights. Why Blind warehouses fall behind:

Inventory inaccuracies: 46% of small to medium sized warehouses report that inaccurate inventory counts cause major fulfilment delays.

Lost productivity: Employees spend unnecessary hours locating stock or manually inputting data.

Delayed decisions: Without a clear operational picture, response times to disruptions are slow.

Cost inefficiencies: Overstocking or stockouts often occur due to poor forecasting and limited data.

Fragmented data: Warehouses often gather data in pieces, leading to disconnected insights that fail to represent the full picture.

The reality is clear: a lack of visibility is no longer sustainable. As customer expectations around speed and accuracy rise, blind decision-making becomes a liability.

What does it mean to become an Observable warehouse?

An Observable warehouse collects and records real-time data from all parts of its operations. This includes: Inventory movement and placement; Autonomous robot paths and performance; Warehouse environmental conditions; Inbound/outbound logistics and cycle times; Labour allocation and productivity.

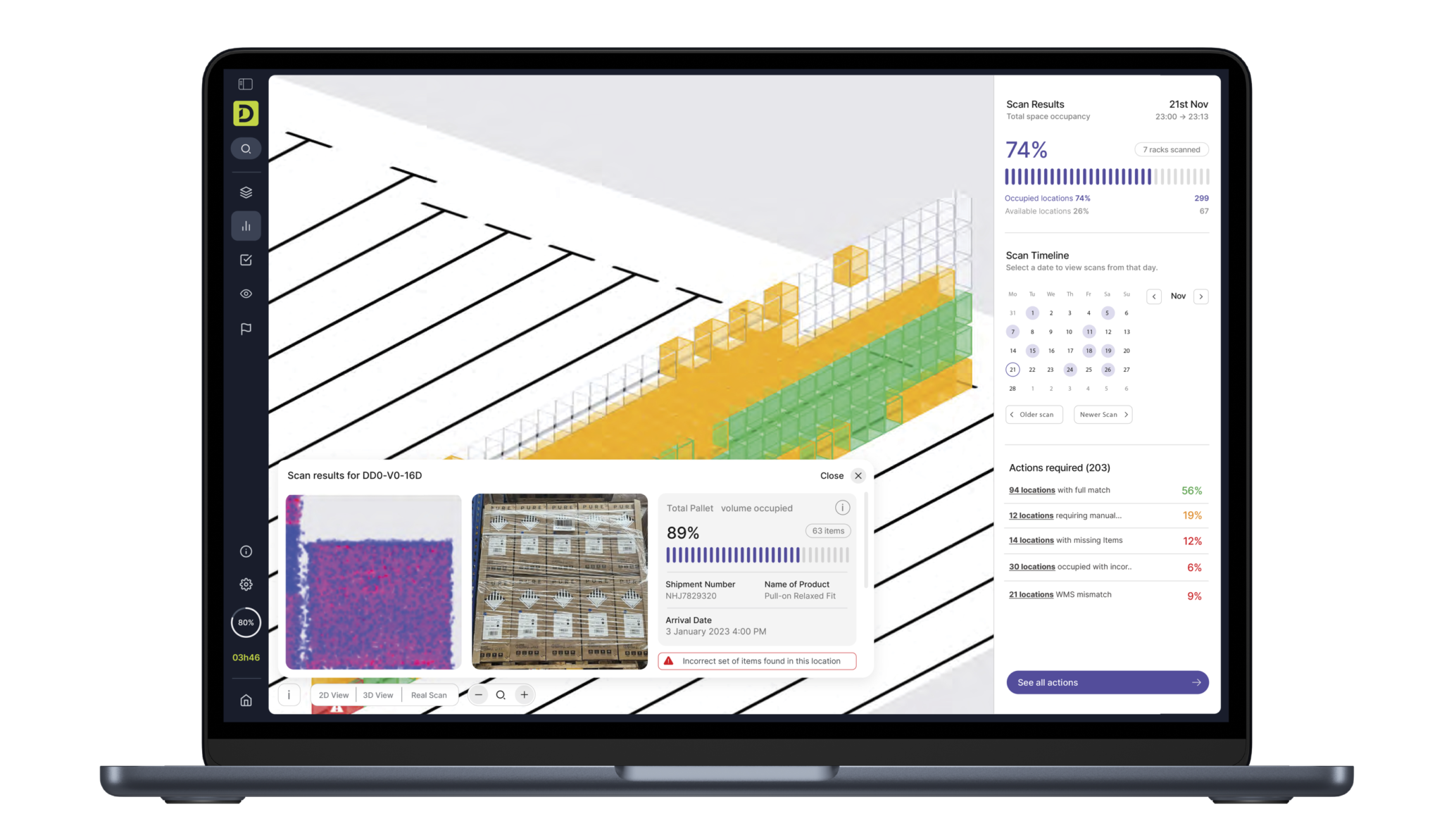

Being observable doesn’t require full automation overnight. It means implementing systems that can provide visibility through sensors, IoT devices, AMRs (Autonomous Mobile Robots), computer vision, or digital twin platforms. For example, Ziegler selected Dexory to provide a scalable, reliable solution capable of operating seamlessly within the warehouse’s existing infrastructure. The deployment of DexoryView has delivered rapid and measurable value for Ziegler’s UK operations, including:

Faster stock recovery and fewer errors: The team is now able to quickly locate missing pallets, detect mispicks early, and address labelling or placement errors in real time – without halting operations. End of costly shutdowns for stock takes: Where full stock takes once required four days and weekend shifts, inventory is now continuously monitored – eliminating the need for disruptive audits and manual reconciliations.

The benefits of visibility

Becoming an Observable warehouse is the foundation for all other advancements. Here are several benefits:

Faster, smarter decisions: Managers gain immediate insights to prioritise tasks or reroute workflows.

Increased productivity: Time spent searching, scanning, and checking can be replaced with actionable data.

Reduced waste and errors: Real-time data reduces the risk of duplication, overstocking, or misplaced inventory.

Foundation for AI and automation: Visibility enables the implementation of intelligent systems that require real-time data to operate effectively.

For example, DCL Logistics has realized significant operational gains since deploying DexoryView:

14% increase in pallet location accuracy: With more precise data, the company has improved inventory reliability, reducing errors and improving fulfillment speed.

10x faster inventory counting: Compared to previously trialled drone-based systems, DexoryView delivers a tenfold increase in the speed of inventory counts – without disruption or downtime.

16 hours of labour saved per day: Eliminating manual inventory checks has freed up staff to focus on high-value strategic initiatives, such as warehouse space optimization and customized projects for clients.

Industry trends driving the need for observability

A few big changes in the industry are driving the move toward more Observable warehouses:

E-commerce growth: Faster delivery expectations mean warehouses must be more agile.

Labour shortages: Observable warehouses help optimise limited human resources.

Supply chain volatility: Data visibility enables real-time responsiveness.

According to a 2025 McKinsey report, companies that invested in real-time warehouse visibility were 33% more likely to exceed customer expectations and reduce fulfilment costs.

Don’t let lack of visibility hold you back

Warehouses can no longer afford to operate without clarity. The first step toward transformation is simple: see clearly. When you do, every other improvement becomes not just possible, but inevitable. Dexory is already helping warehouses across industries make this critical shift. The journey from blind to observable isn’t just a technology upgrade – it’s a mindset shift toward continuous improvement.

similar news

Will 2025 be the year we finally Remove Logistics Blind Spots?