Dexory has secured $19 million in Series A funding led by leading European VC firm Atomico, with participation from existing investors Lakestar, Kindred, Capnamic, and Maersk Growth, the investment arm of the global logistics and container shipping company, Maersk. As part of this investment Atomico Partner Ben Blume will join Dexory’s board of directors.

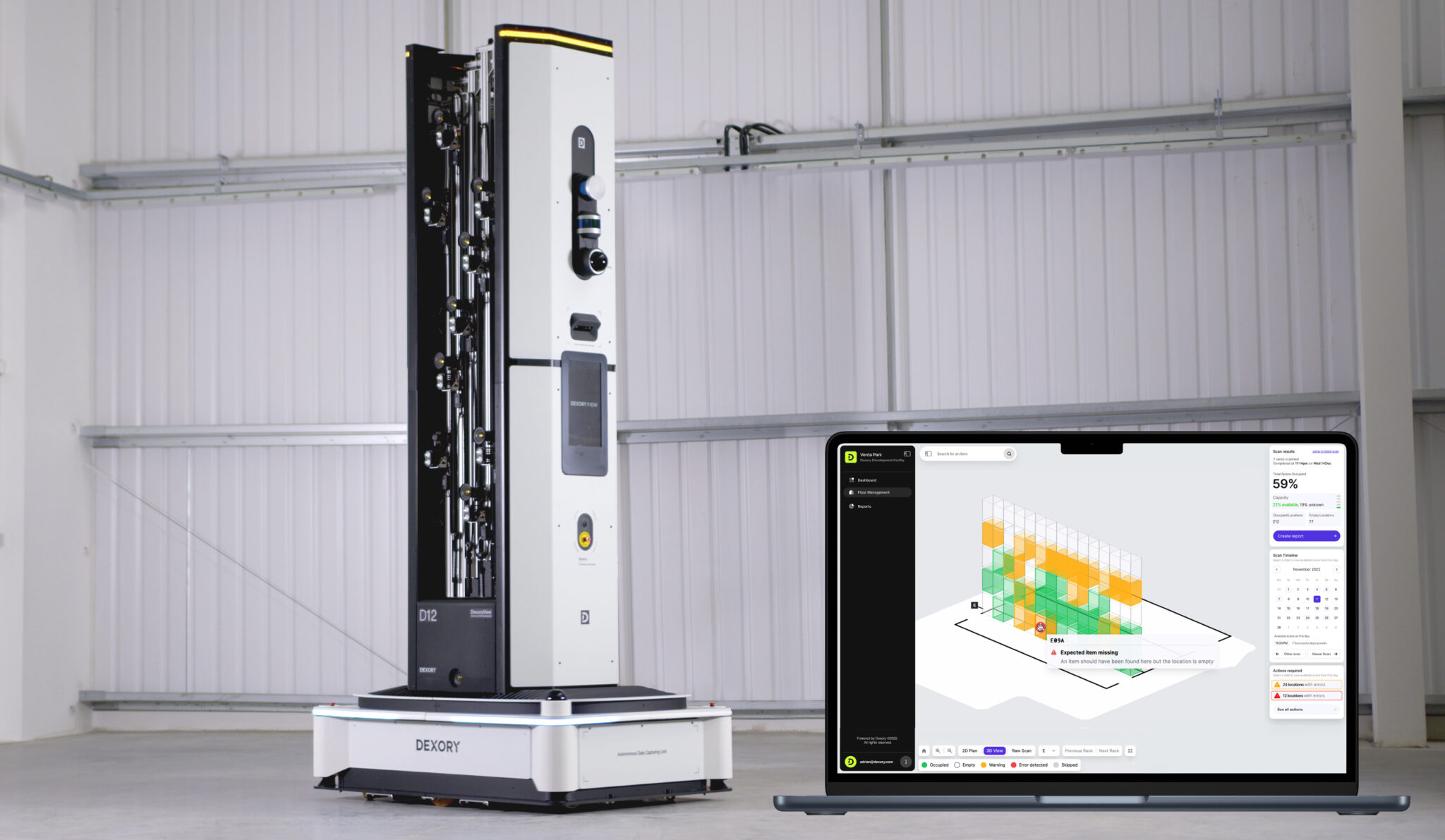

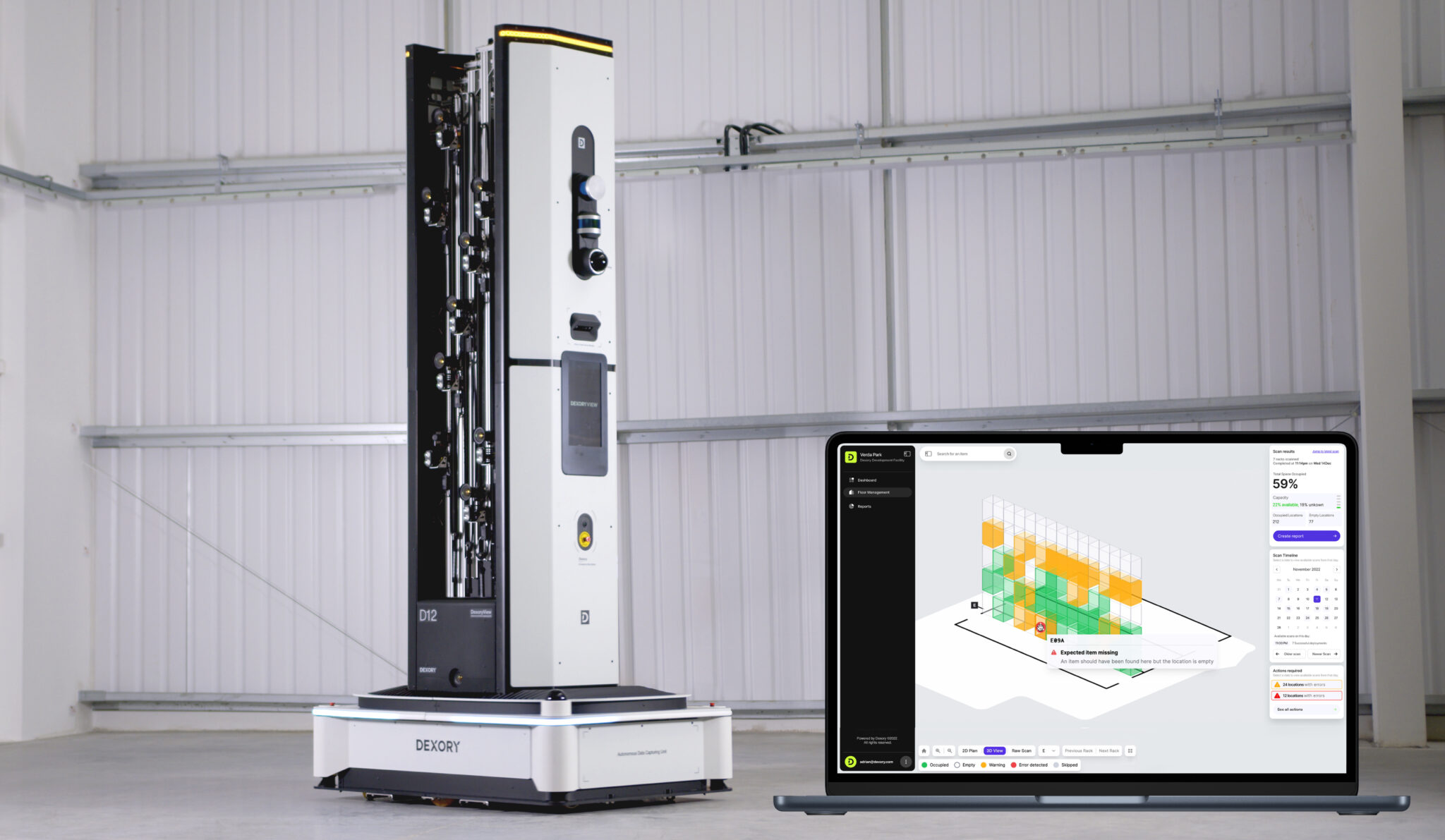

Addressing the urgent need for improved space utilisation and increased efficiencies in warehouses around the world, Dexory combines powerful analytics with autonomous robots capable of capturing rich image and sensor data from across a warehouse. This powerful combination provides comprehensive visibility across warehouses of any size, as well as connecting warehouses across the global supply chain through Dexory’s digital platform, DexoryView.

In the last few years, the combination of a boom in e-commerce, the global Covid-19 pandemic, and the war in Ukraine has sent unprecedented shocks through global supply chains. While the foundational systems that underpin cross-border production and trade have many interconnected moving parts – procurement, manufacturing, packaging, shipping, energy, tracking and distribution – this has been felt particularly acutely in warehouses, the ‘core’ of the supply chain, where goods are stored, sorted, and distributed.

“For those operating warehouses, ensuring 100% fulfilment ‘in time, all the time’ is crucial to meeting the demands of the modern consumer. A critical component to achieving this is high stock accuracy, but staff shortages, manual processes, and the speed demanded by customers means that critical decisions across the supply chain are currently being taken blindly,” said Dexory CEO and co-founder Andrei Danescu. “Technology that is autonomous, real-time, intuitive, and integrated can have a transformative effect on the everyday efficiency, productivity, and accuracy of a warehouse – and form an integral part of revamping businesses supply chain strategies”.

Rising costs, low supply of warehouse units combined with huge demand for goods, and a shortage of labour is putting extreme pressure on the sector to improve space utilisation and increase efficiencies.

Dexory, which is already integrated in leading distribution companies such as Maersk and Menzies Aviation, provides a platform which offers 360 degree visibility into customers’ warehouses, the beating heart of the supply chain. Manual processes often still dominate in these operations and global companies can have up to as many as 500 different warehouse management systems (WMS) running across thousands of their globally distributed warehouses at any one time. This means that expensive manual audits often take place on an infrequent basis, finding lost inventory takes days due to a lack of interoperability between WMS’, and a unified global view is impossible to achieve.

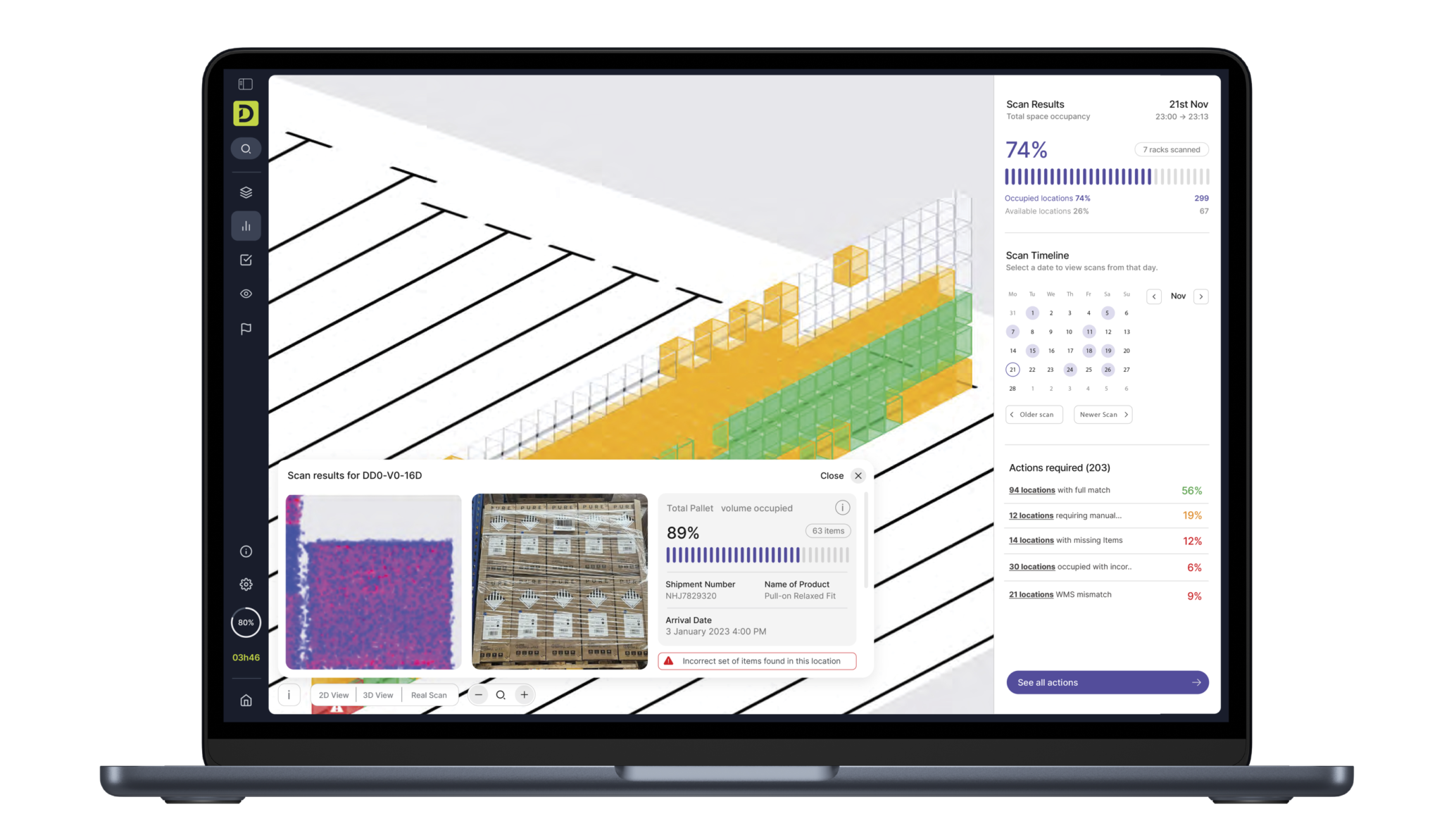

Dexory’s platform, DexoryView, can perform a full warehouse scan in just a matter of hours, around 100x faster than humans, giving customers an immediate view of the core hub in their supply chain. This gives customers enhanced inventory visibility, with DexoryView’s dashboard tracking detailed location of goods, allowing for the quick identification and location of items, accurate information on stock levels and locations, and better decision-making in warehouse operations.

And customers can also use DexoryView as a ‘digital twin’ replica of their warehouse to help not only manage, but get the most out of warehouse performance – allowing for the software to optimise, simulate and predict future scenarios. All of this frees up human workers to focus on more complex activities, leading to improved productivity, better resource allocation, and the ability to handle higher order volumes efficiently.

“For an operation as complex and sophisticated as running a modern warehouse, the current lack of an automated way to capture data about the physical space is a major pain point”, said Atomico Partner Ben Blume, “We’re hugely excited by the promise, and market traction, of Dexory’s technology with leading global logistics companies like Maersk and Menzies Aviation. Through creating a digital replica of the warehouse with their advanced robotic data capture technology, they are able to deploy a platform that is not only seamless and intuitive, but provides powerful and actionable insights too.”

This Series A funding round will be used for international expansion in key markets such as the US, and Central and Northern Europe, with aims to double Dexory’s workforce by the end of the year to support unit deployment functions and increased production. The funding will also be used to continue developing Dexory’s forecasting and simulation technology; as well as accelerating the production of its automated robots in its facility in the U.K.

In doing so, Dexory hopes to continue to embed accurate and real-time data into its customers’ supply chains, making it the new standard for the warehouse of the future.

Dexory was founded in 2015 by three founders, Andrei, Oana and Adrian (pictured), and is based in the UK. The founders are school friends from Romania, who moved to the UK a decade ago with experience accumulated across engineering and tech roles at Formula 1, Google, and IBM. Combining commercial nous with deep technical expertise, the three founders are now working together to help transform warehouse management practices worldwide.