Dexory has added a view optimisation module to its existing suite of warehouse optimisation technologies. Peter MacLeod, Editor, finds out more.

In the fast-paced world of logistics, visibility and efficiency are no longer luxuries – they’re necessities. UK-based scale-up Dexory is addressing these needs head-on with cutting-edge automation and AI-powered optimisation tools. What began as a solution for real-time stock reconciliation has rapidly evolved into a comprehensive warehouse intelligence platform, and its benefits are being harnessed across industries and continents.

Understanding Customer Needs

Customers don’t always know exactly what they need, at least not at first. That’s something Dexory understands deeply. “They come to us with a specific pain point,” Tatiana Kalinina (pictured, below), Dexory’s Vice President Business Development told me during a break in activities at LogiMAT, “but as we dive deeper into their operations, we uncover opportunities for broader value.”

Dexory’s approach begins with a detailed discovery process, analysing a client’s unique warehousing challenges. The initial offering is straightforward: an impressive robot-enabled solution that performs daily, wall-to-wall inventory scans, a tried-and-tested bit of tech about which we’ve previously written in Logistics Business. These scans eliminate the visibility gaps that plague many warehouses and reduce the need for time-consuming, error-prone manual stock checks.

The benefits extend beyond the bottom line. By automating low-value tasks, employees are freed up to focus on higher-level work. One client saw warehouse staff transition from stock counters to operations analysts within weeks. This shift not only boosts morale but also strengthens staff retention – an increasingly critical factor in today’s competitive labour market.

ROI Speaks for Itself

Return on investment is top of mind for every warehouse manager. While Dexory’s solution may seem intangible at first glance, the company has taken a pragmatic approach to proving its value. “We don’t throw numbers around,” Kalinina explains. “We assess each client’s operations in detail and create quantifiable value buckets.”

This method allows Dexory to show measurable ROI, often within 12 months. For some, the savings come from eliminating stock inaccuracies that cause delays or missed deliveries. For others, it’s about reclaiming labour hours or optimising warehouse space. The point is, the ROI is real, and Dexory takes the time to tailor the metrics to each customer’s priorities.

One of the strengths of the Dexory solution is its scalability. The company frequently starts with a pilot deployment in a single warehouse, often chosen for its high complexity or interesting operational issues. From there, expansion tends to happen quickly. “With many of our 3PL customers, we’re seeing growth across multiple sites in under three months,” says Kalinina. “Sometimes even faster.”

This rapid scale is driven by Dexory’s ability to deliver consistent value across varied environments, from massive DCs in Germany to smaller, bonded warehouses where stock traceability is paramount. Whether the goal is speed, accuracy, or compliance, the system has the capability to adapt.

Optimisation Module

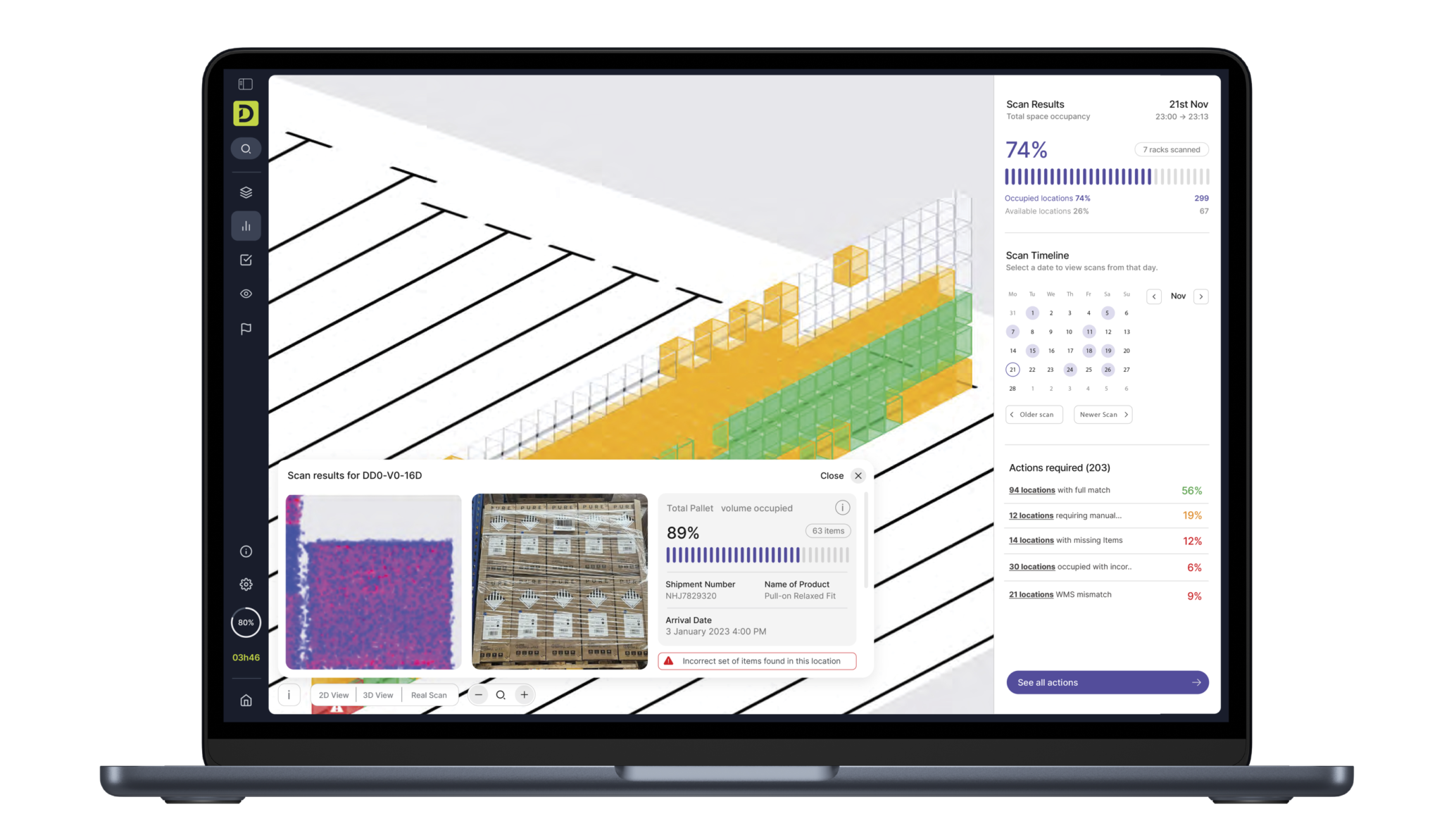

Dexory’s latest innovation is its View Optimisation Module, a powerful extension of its core offering. This new capability taps into the company’s digital twin and data collection backbone to provide actionable insights into warehouse layout, space utilisation, and process flow.

“Inventory accuracy is just the beginning,” says Kalinina. “Now, we’re feeding in wider KPIs, things like congestion, replenishment cycles, outbound flow, and item velocity, to recommend operational changes that drive further efficiency.”

It’s a major leap toward intelligent, self-optimising warehouses. Customers can identify in real-time high-traffic zones, consolidate storage for efficiency, and streamline picking operations.

While Dexory’s roots are in the UK, the company has its sights firmly set on international growth. With a strong presence in Europe, it is investing heavily in its global operations. In particular, the US market, where it has a growing presence, is a major focus.

“We’ve already got our office in Nashville, and our head of US operations is embedded in the market,” Kalinina says. “That boots-on-the-ground presence helps us connect with customers quickly and deliver seamless service.”

The Middle East is also on the company’s radar, especially following a recent funding round that included investors from the region. However, Dexory remains focused on cementing its position in its core markets before expanding further afield.

Best of Both Worlds

Despite its rapid growth, Dexory retains the agility of a startup. The team appears to be able to move quickly, iterate constantly, and maintain a close connection with customers. At the same time, they’ve implemented the processes and systems necessary to scale sustainably.

“We’re already supporting deployments in Australia and delivering hardware on tight timelines,” Kalinina notes. “But we’re also preparing for the future – whether it’s 10, 50, or 100 new warehouse sites.” This blend of startup agility and enterprise readiness is rare, and it’s helping Dexory earn the trust of some of the logistics world’s biggest players.

The Road Ahead

Looking to the future, Dexory is not standing still. The company’s digital twin technology and robust data infrastructure provide a strong foundation for ongoing innovation. “We’re constantly building new modules, always based on customer needs,” Kalinina tells me. In the near term, that means deeper insights into space occupancy, pick path optimisation, and even real-time replenishment recommendations. Over time, it could mean even more predictive and prescriptive capabilities.

Perhaps the strongest testament to Dexory’s value is its customer retention. In the past year, the company has experienced rapid expansion and not a single customer has walked away. “Zero churn,” Kalinina smiles. “We’re proud of that.”

In an industry where time is money and margins are tight, Dexory has demonstrated that visibility, automation, and optimisation aren’t just nice to have – they can prove to be game-changers.