DHL and New York University’s Stern School of Business today released the new DHL Global Connectedness Report 2024, the most comprehensive available analysis of globalization’s state and trajectory. It tracks how flows of trade, capital, information, and people move around the world and measures the globalization of 181 countries and territories.

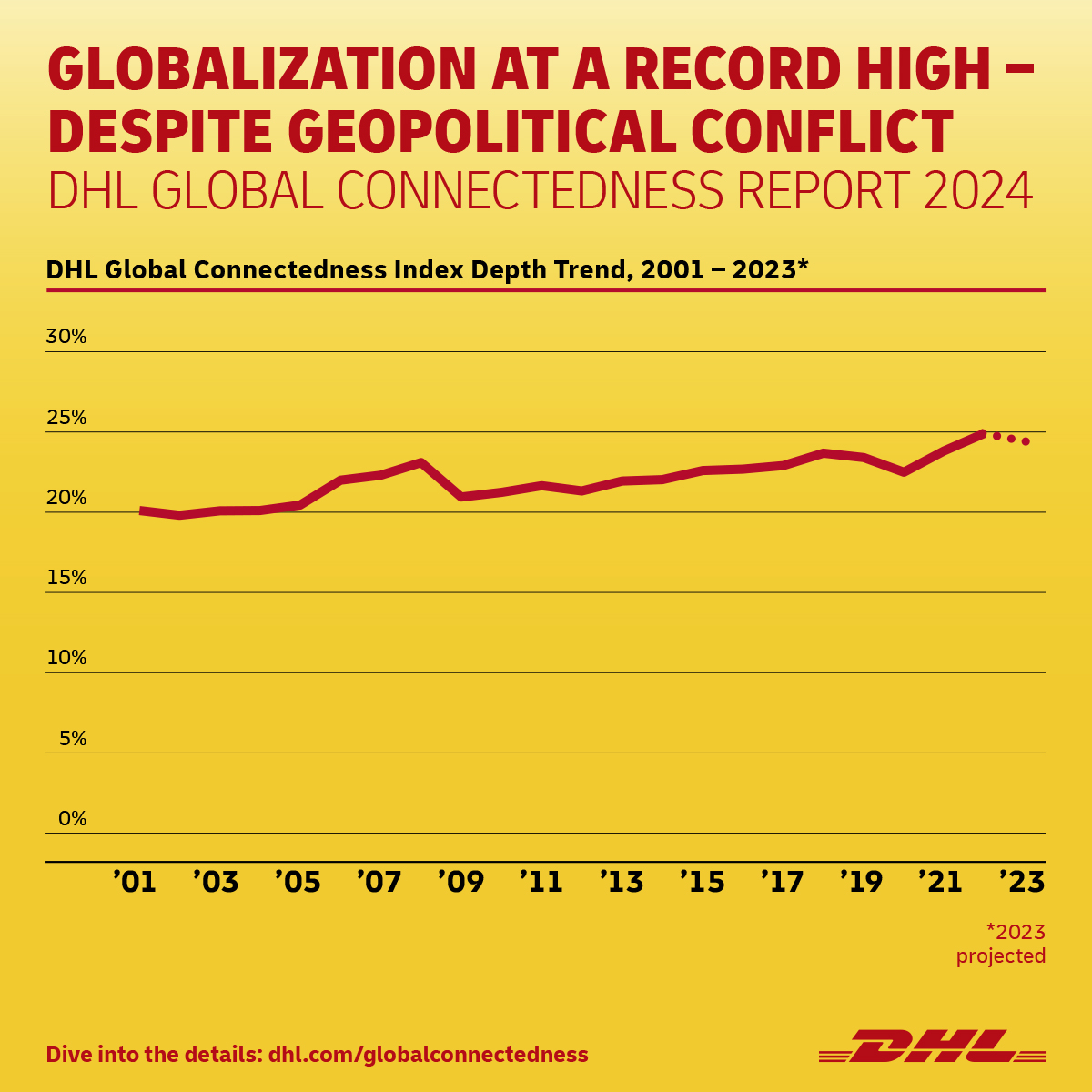

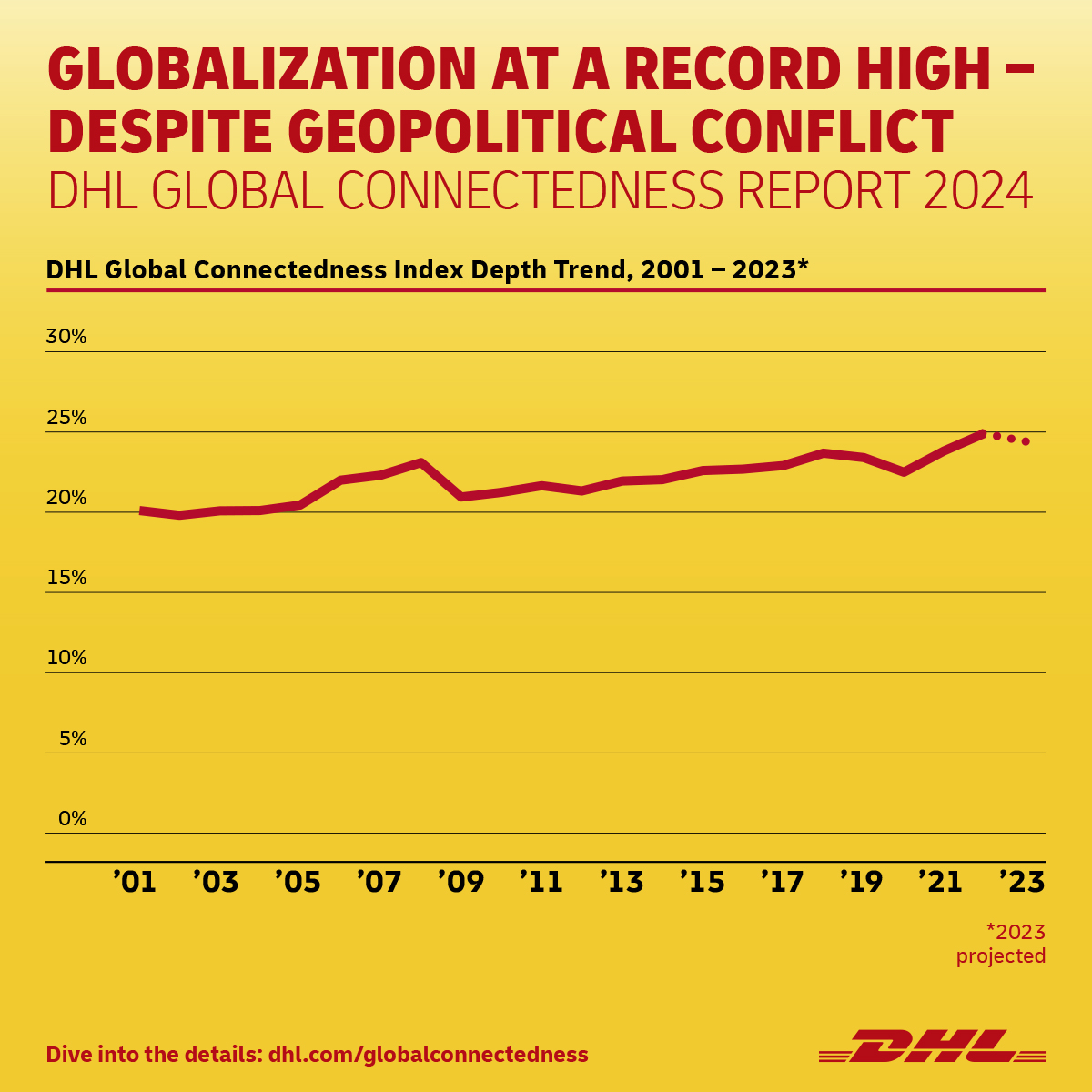

The report reveals that globalization reached a record high in 2022 and remained close to that level in 2023 – despite a series of global shocks over the past decade, including the Covid-19 pandemic, wars in Ukraine and Gaza, the U.S. – China trade conflict, and the UK’s withdrawal from the EU. The evidence strongly rebuts the notion that the growth of global flows has gone into reverse. Trade growth played a crucial role in boosting global connectedness. The share of global output traded internationally was back to a record high level in 2022. After a slowdown in 2023, trade growth is forecast to accelerate in 2024. The globalization of information flows has been especially strong over the past two decades, even though the latest data show a stall in their growth, partly due to less research collaboration between the U.S. and China. Corporate globalization is rising, with companies expanding their international presence and earning more sales abroad.

At the launch of the DHL Global Connectedness Report, John Pearson, CEO DHL Express, said: “The most recent findings of the DHL Global Connectedness Report unequivocally dispel the notion of globalization reversing course. Far from being a mere buzzword, globalization is an influential force that has profoundly reshaped our world and has further great potential. Expanding markets and fostering opportunities empower individuals, businesses, and entire nations to flourish in unique ways. Embracing globalization allows us and our customers to forge a promising future, fostering an increasingly interconnected world, more prosperous for all – and poised for further growth.”

The report affirms the considerable potential to continue growing global flows. It pegs the world’s current level of globalization at only 25%, on a scale from 0% (meaning no flows cross national borders) to 100% (borders and distance have ceased to matter at all).

Ranking of most globalized countries

Singapore achieves the number one spot. The Netherlands and Ireland rank the second and third. 143 countries became more globally connected, while only 38 saw their levels of connectedness decline. Further evidence shows that Europe is the world’s most globally connected region, followed by North America and the Middle East & North Africa.

“Singapore has invested heavily in strengthening our physical and digital connectivity to the world because trade is our lifeblood. We continue to enhance our connectivity and trade links to remain a critical and trusted node in global supply chains, facilitating international trade and flows of capital, information and talent. We look forward to partnering with global companies seeking a launchpad for business growth and supply chain expansion in Asia-Pacific and beyond,” said Ih-Ming Chan, Executive Vice President, Singapore Economic Development Board.

U.S. – China ties diminish, and Russia shows unprecedented decline

The DHL Global Connectedness Report also shows that U.S.-China ties continue to diminish, with the shares of both countries’ flows involving each other decreasing by about one-quarter since 2016. However, both countries remain significantly connected, demonstrating larger flows than almost any other pair of countries. Russia and Europe have decoupled, resulting in Russia facing an unprecedented drop in connectedness, more than twice as much as any previous decline on record among the world’s 20 largest economies. At the same time, the data analysis demonstrates that there is no wider split of the world economy between rival geopolitical blocs.

Globalization has not given way to regionalization

Further, the report shows that predictions of a global shift from globalization to regionalization are not – at least yet – borne out in patterns of international flows. In fact, most international flows are taking place over stable or even longer distances, with a declining share happening inside major geographic regions. In the realm of trade, only North America shows a clear shift to more regionalized trade patterns.

“Deglobalization is still only a risk, not a current reality,” says Steven Altman, Senior Research Scholar and Director of the DHL Initiative on Globalization at NYU Stern’s Center for the Future of Management. “Geopolitical threats and public policy shifts have led many to predict a fracturing of the world economy along geographic or geopolitical lines, or even a retreat from international to domestic business. But the latest data still show that international flows are growing and very few countries are cutting ties with their traditional counterparts. It is important to recognize the resilience of global flows because a lopsided focus on the threats to globalization could make deglobalization a self-fulfilling prophecy.”

Published regularly since 2011, the renowned DHL Global Connectedness Report provides reliable findings on globalization trends by analyzing 15 types of international trade, capital, information, and people flows. The 2024 edition is based on almost nine million data points. It ranks the connectedness of 181 countries, accounting for 99.7 percent of the world’s gross domestic product and 98.7 percent of its population. A collection of 181 one-page country profiles provides concise summaries of individual countries’ globalization patterns.

The report was commissioned by DHL and authored by Steven A. Altman and Caroline R. Bastian of New York University Stern School of Business.

read more

DHL Index: Globalisation resilient during pandemic