Risk mitigation is imperative to reduce the risks of and damage from cyberattacks and other crises, writes Robert Strange (pictured below), Senior Engineer at Neo4j.

Supply chains have evolved into highly connected networks in recent years, driven by technological advancements that have made them ‘smarter’. While these innovations have positively transformed business operations, they have also opened avenues for new vulnerabilities, leaving supply chains susceptible to disruptions in both the physical and digital realms.

The growing risk of cybersecurity is a prime example of these vulnerabilities. The ransomware attack on Blue Yonder, a supply chain management software specialist, highlighted the severe disruptions such incidents can cause. This attack compromised the company’s managed services environment, leading to delays at several grocery and retail stores across the UK – delays not just in delivering goods but also in paying staff and managing schedules.

Blue Yonder’s attack underscores the need for scenario planning and robust mitigation plans to safeguard against these risks. These incidents can bring production to a standstill and significantly disrupt business revenues if plans to contain potential impacts are not mapped out in advance. Data plays a central role in keeping supply chain operations running efficiently and effectively, but the reality is these supply chains are currently not being safeguarded or optimised to withstand real-world disruption. As a result, many businesses are turning their attention to innovative technologies and strategies to strengthen resilience throughout their supply chains.

Overcoming the challenges of supply chain visibility

Supply chains are inherently complex in nature; a vast network of producers, warehouses, transportation systems, distribution ports, and stores from around the world. A single disruption in any part of this network can send the entire system into disarray, making visibility crucial in preventing a domino effect. Nonetheless, extracting valuable insights from raw supply chain data presents its own set of challenges. Traditional data models, which rely on rigid structures of tables, rows, and columns, struggle to effectively capture the intricate relationships between different data sets. Inflexible in their structure, analysts using these models have limited ability to extract valuable insights that could inform a response to disruption.

Mapping connections for smarter supply chains

This is where graph databases come into play. Traditional data models struggle with complex relationships, while graph databases offer a more dynamic approach. In this model, ‘nodes’ represent entities, like people, products, or locations, while ‘edges’ represent the relationship between two nodes – i.e., how they are connected to one another. The unique structure of graph databases is especially valuable for supply chain professionals wanting to benefit from digitally visualising their supply chain as the interconnected network that it is.

To optimise transportation, a supply chain organisation could, for instance, create nodes to represent each wholesaler and retailer. These could be connected by edges to show the distances between them. Then, by running the appropriate query or request in the data model, the analyst should be provided with what should be the ‘best’ – fastest and cheapest – supplier from which goods can be transported ready for purchasing.

Understanding the relationship between different entities in advance can also be invaluable when dealing with unexpected disruption. Take the crisis in the Red Sea, for instance, where shipping companies are facing rising costs and delays due to rebel attacks. Graph technology could allow those managing supply chains to identify alternative routes or solutions pre-emptively, ensuring goods reach suppliers more efficiently, enhancing resilience, and minimising disruption.

The power of graph databases lies in their ability to map complex relationships between entities, making them a crucial tool for uncovering insights. Supply chains, which operate as networked structures, are naturally suited to this model, while the rigid format of traditional models makes it much harder to reveal these relationships.

Predicting and preventing disruption with digital twins

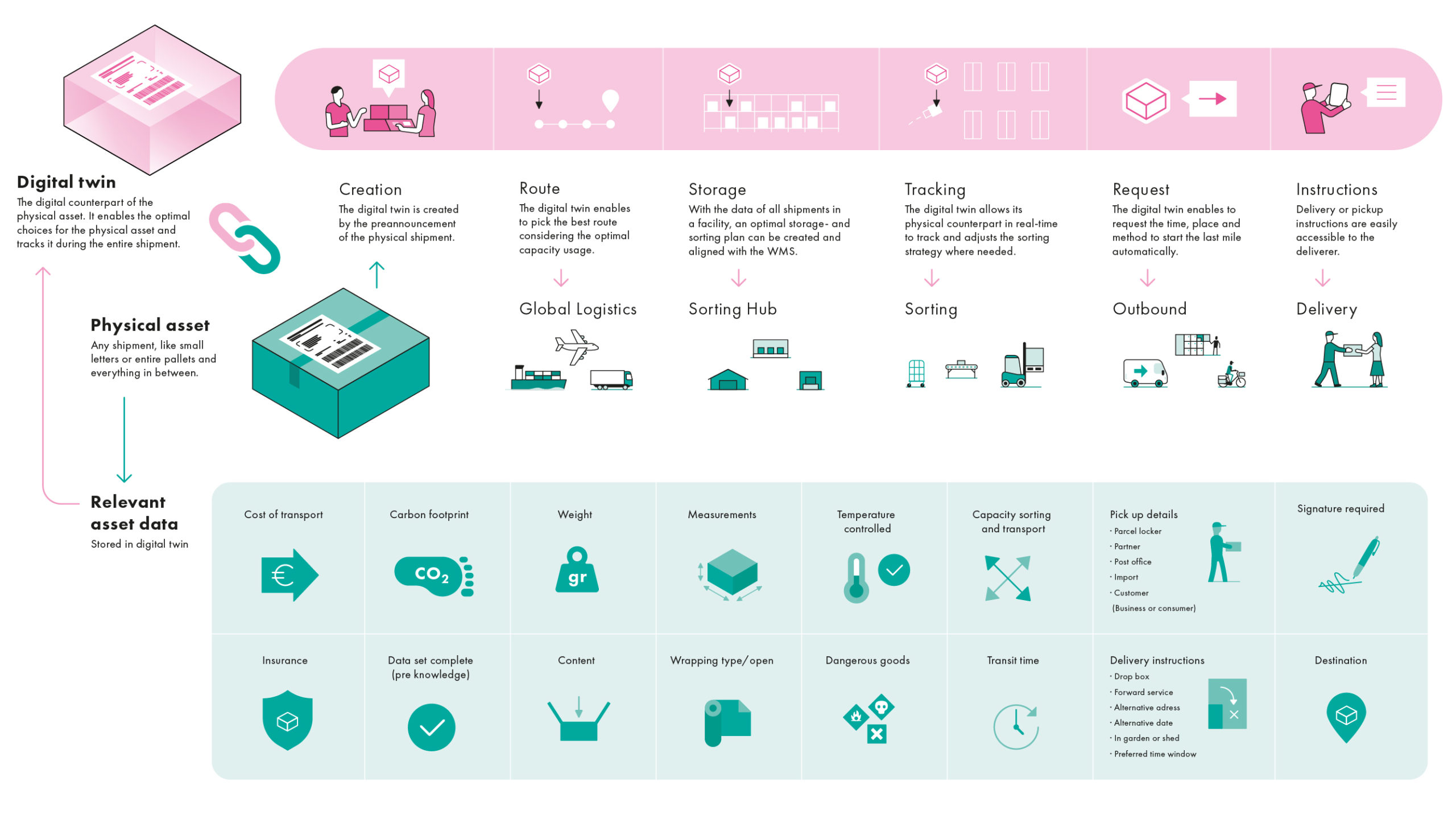

Supply chain resilience isn’t just a case of managing physical disruptions, it’s also about preparing better responses to those in the digital realm. Cyberattacks can significantly disrupt digital operations. As such, businesses are exploring digital twin technology as a tool for proactively combatting potential issues before they arise and conducting post-incident analysis.

Organisations are creating virtual replicas of their supply chains called ‘knowledge graphs’ to test different scenarios and predict multiple outcomes of cybersecurity risks. This means a connected, virtual model provides a comprehensive view of the supply chain and allows companies to understand how these systems interact at both a granular and holistic level. This picture encompasses the users and the groups they belong to, and the permissions granted to each member. As recurring or interconnected events are captured over time, the digital twin becomes more accurate. This enables both cybersecurity and supply chain analysts to act swiftly and more effectively while informing how they respond in the future.

Making these connections visible to cybersecurity analysts helps identify the most critical vulnerabilities and the potential attack paths that threaten resources. Analysts can then assess the likelihood of successful attacks by attaching the probabilities to each of those pathways, enabling them to reinforce security measures accordingly.

This insight is valuable because it clearly signposts when organisations need to map out other viable routes, reassess transit times, and evaluate cost implications. By combining cybersecurity modelling with supply chain optimisation, organisations create a powerful strategy that allows them to stay ahead of disruptions and re-prioritise resources in quicker succession.

Getting a grip on future events

As supply chains become more interconnected and worldly disruptions more unpredictable, organisations should aim to make the most of their connected data. By leveraging graph databases, companies can uncover insights into the relationships within their data, allowing them to proactively identify vulnerabilities and navigate uncertainty with confidence.

similar news