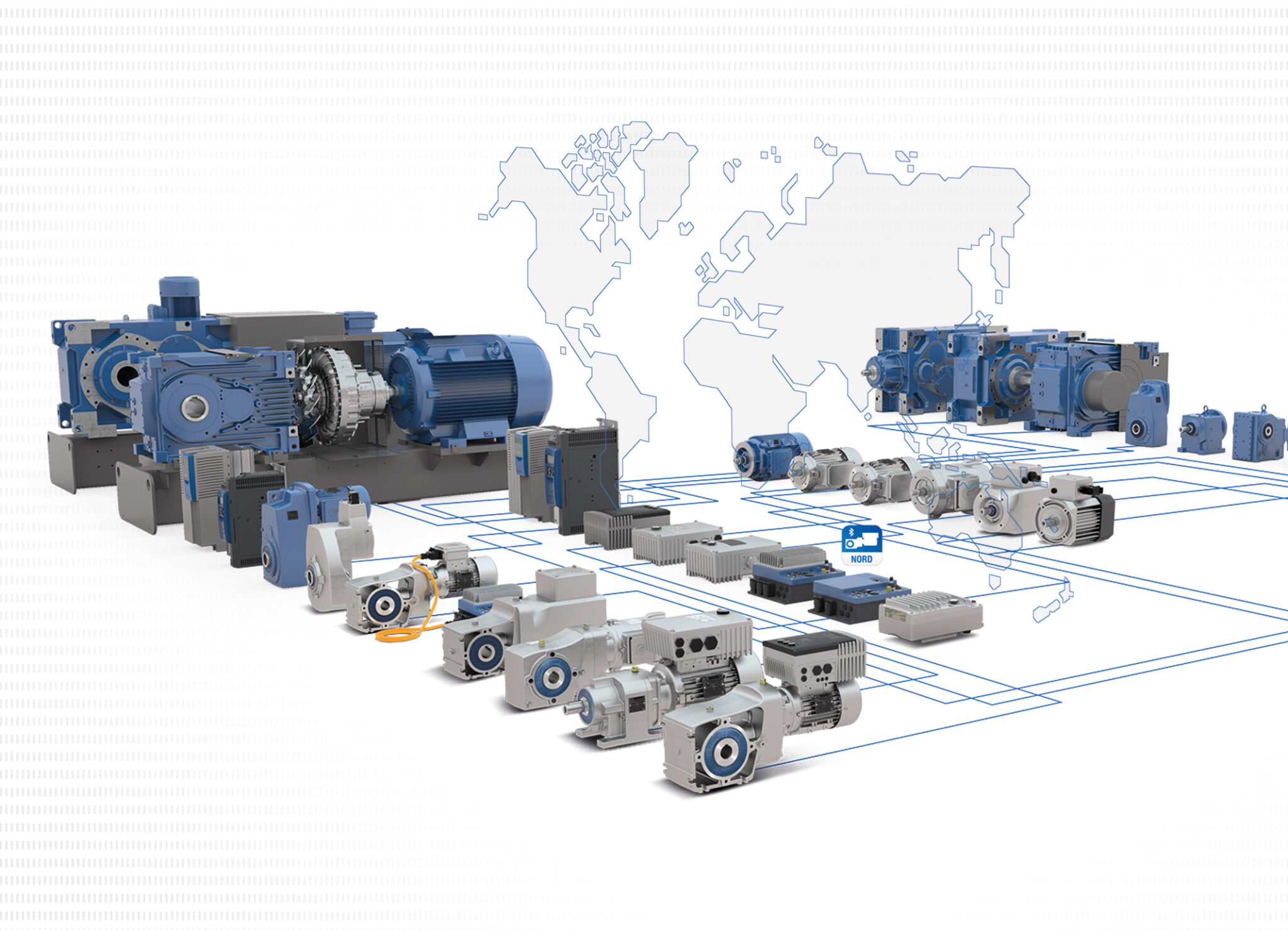

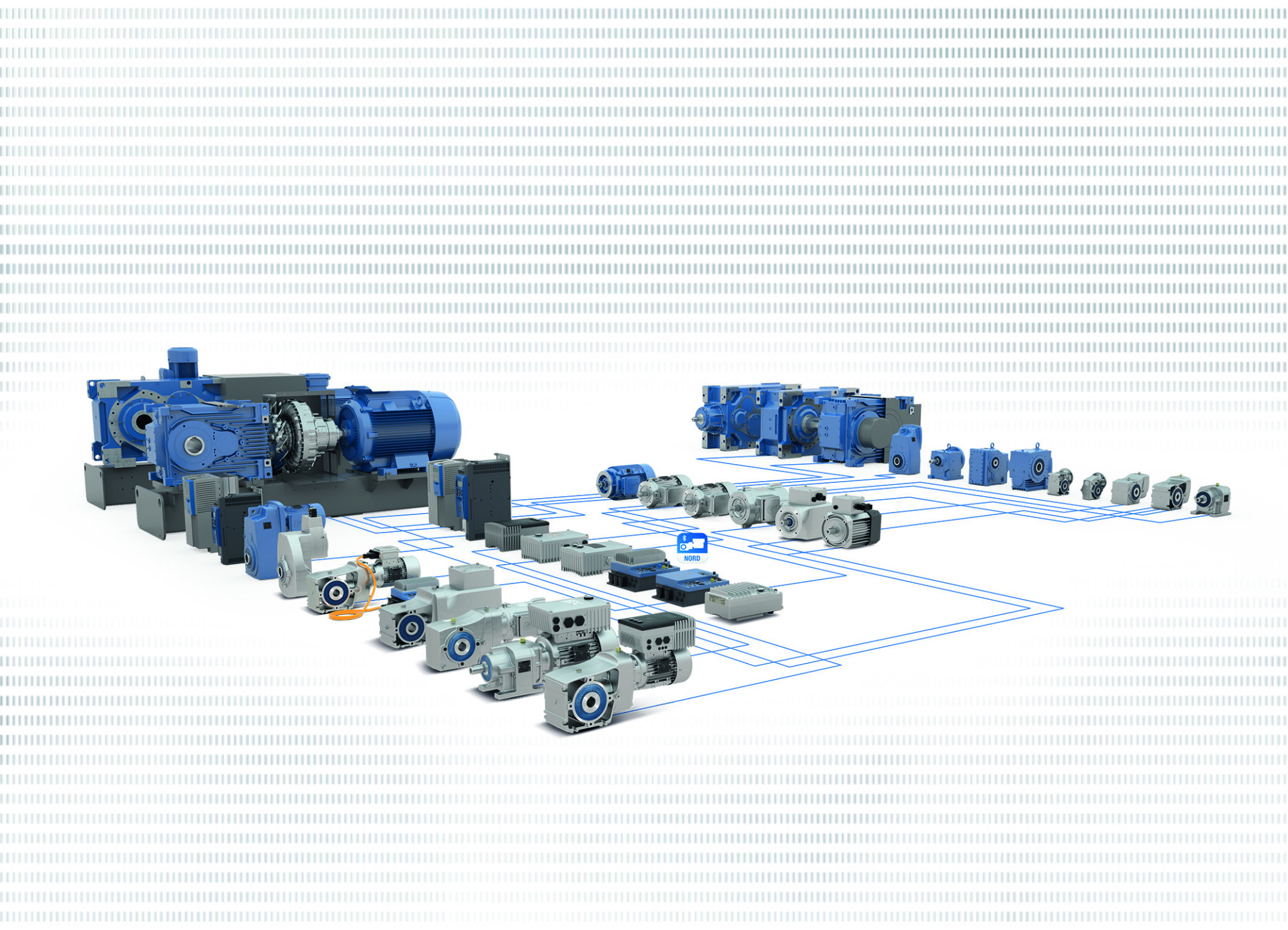

Whether conveying goods or lifting heavy loads, every movement needs a drive system. However, different applications have different requirements. As a developer of drive solutions, NORD offers via its modular product range all components of drive technology that can be combined in various configurations.

NORD implements the appropriate selection, design and calculation of the drives. Drive systems consisting

of gear unit, motor and drive electronics thus become tailor-made solutions for specific industry applications. Hence, the company is able to fulfil a wide range of specific requirements.

A modular system offering numerous solutions

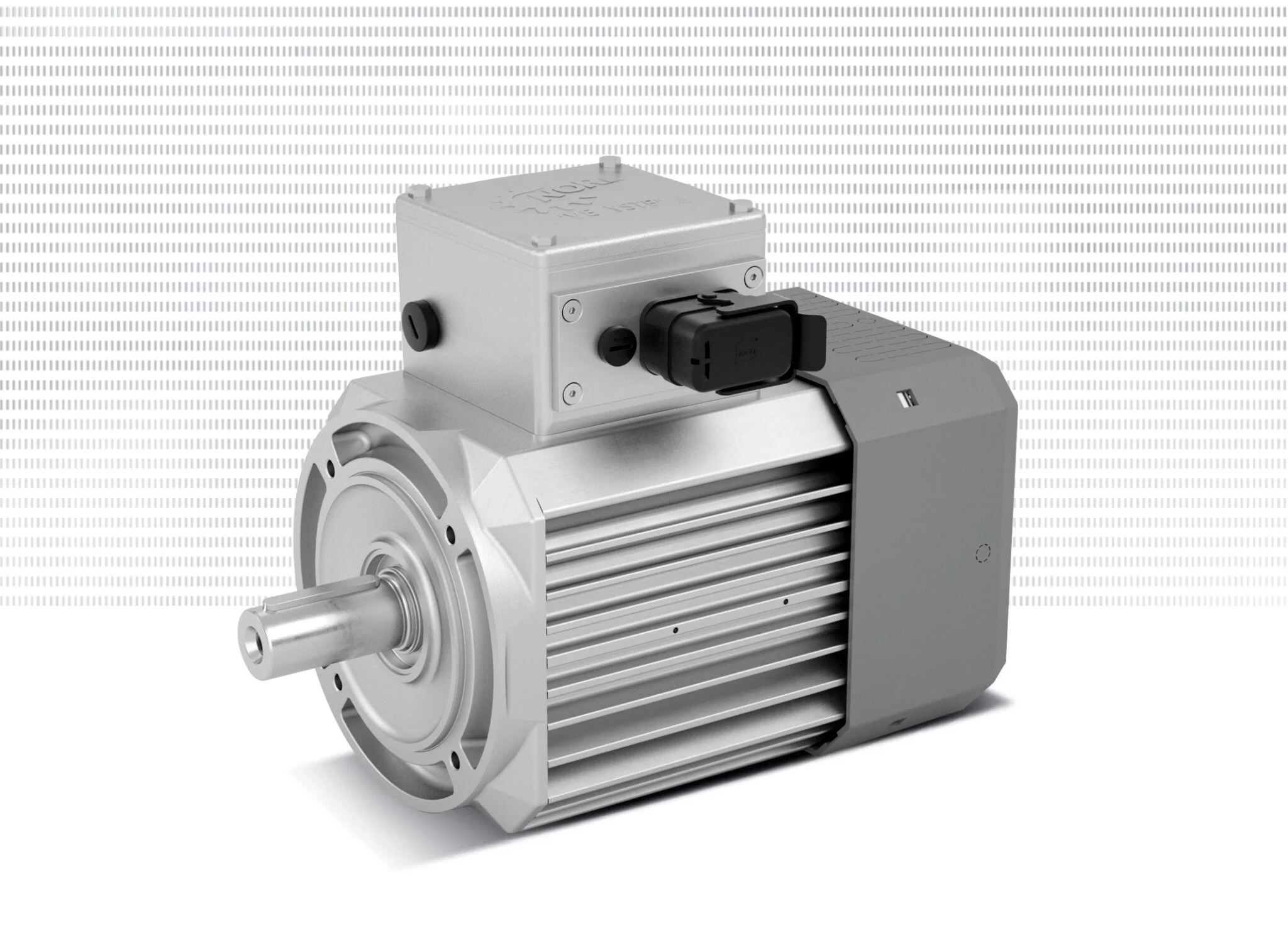

One example is the requirement for energy efficiency. NORD has electric motors that can be used worldwide and comply with all relevant international regulations. With its IE5+ synchronous motors, the developer surpasses the efficiencies of the currently highest defined energy efficiency class (IE5). They are also part of the integrated gear unit/motor concept DuoDrive that combines the IE5+ motor with a single-stage helical gear unit in one housing. DuoDrive achieves one of the highest efficiencies on the market within this power class. Users also benefit from expertise and additional services, such as the NORD ECO efficiency analysis that allows the implementation of upcoming drive tasks with optimal energy consumption.

Another current example is condition monitoring that NORD can integrate into its drive solutions. With an IIoT solution, it is possible to determine and analyse drive and status data via the integrated PLC of the frequency inverter. The data can also be made available to the central systems of the users. This provides important information for predictive maintenance, allowing machinery and equipment to be maintained proactively, while reducing downtimes and increasing overall system efficiency.

Solutions to optimise user performance

“Requirements are changing – and we are actively following this path” reports Jörg Niermann, Head of

Marketing at NORD. “We are continuously developing our drive components to provide our customers with

solutions that help them progress technically, economically and environmentally.” By combining a wide

modular product range with technical expertise and knowledge in more than 100 industries, NORD creates

drive systems that are tailored to specific needs and delivered as complete solutions from a single source.

Similar News…