Bonfiglioli’s tailored drive solutions are at the heart of a smarter, more connected future for manufacturers of AGVs and AMRs, writes Editor Peter MacLeod.

As demand for autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) surges across logistics and warehouse environments, Bonfiglioli, a long-established Italian manufacturer of gear motors and drive systems, is turning its attention to providing customised, compact, and connected solutions for OEMs. Cristiano Cattan, Global Key Account Manager, sat down with us at LogiMAT to discuss the company’s evolution and innovation trajectory.

“We’re seeing significant growth in the AMR space,” Cattan explains. “And what we’ve learned is that this is a very different business from traditional industrial markets. OEMs don’t want off-the-shelf components, they want tailored solutions.”

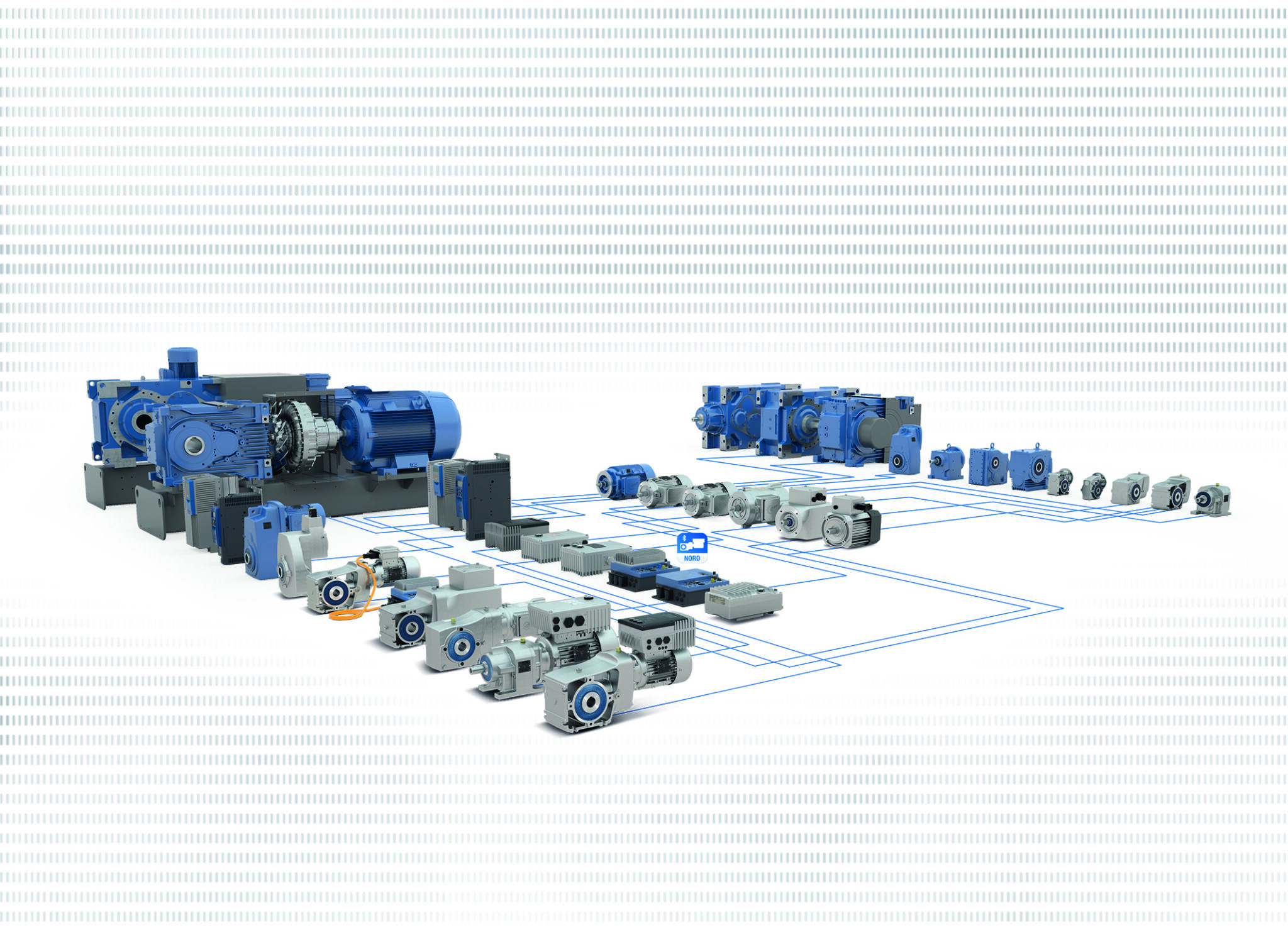

Bonfiglioli, known historically for industrial gearboxes, continues to expand its offering of integrated systems that combine motors, gear units, and drive controllers. This shift is more than a product evolution, it’s a strategic move to meet customer demands for turnkey solutions and to help them reduce their roster of component suppliers.

“Today, customers are coming to us not for a gearbox, but for a compact, all-in-one drive solution,” says Cattan. “They’re saying, ‘Here’s the performance spec and physical dimensions, can you build something that fits?’ And we’re answering yes, with a collaborative engineering approach between their R&D and ours.”

Valued Partner

This high-touch engagement has made Bonfiglioli a valued partner for OEMs building AMRs and AGVs, especially in space-constrained applications. It’s also pushing the company deeper into electronic integration. The 2023 acquisition of Selcom Group, an Italian electronics manufacturer, has bolstered Bonfiglioli’s in-house capabilities in drive control and edge computing, opening the door to smarter, IoT-enabled systems.

“We now offer solutions that include condition monitoring and predictive maintenance,” says Cattan. “Our gear motors can report live data on temperature, vibration and load. That means operators can identify wear or potential failures before they cause downtime.”

These insights are transmitted either through the customer’s PLC or via Bonfiglioli’s edge computing devices, enabling residual lifetime analysis of components like bearings and motors. “Customers don’t want to stop a line, even for a second,” Cattan (pictured below) adds. “So being able to plan maintenance before failure is a real value-add.”

Broad Portfolio

Despite these advances, Bonfiglioli’s challenge remains market perception. “We’re still seen by many as just a gearbox supplier,” Cattan says. “But we have a broad portfolio and deep flexibility to go beyond it. We want the industry to know that Bonfiglioli offers full, intelligent drive solutions.”

Indeed, that flexibility has proven crucial, not only in AMRs but also in fixed logistics applications. While Bonfiglioli isn’t embedded in global giants such as Amazon or DHL, Cattan notes a rising interest in their smart conveyor solutions, especially for airport baggage handling and intralogistics systems.

As it evolves its product portfolio, Bonfiglioli is also positioned for a global customer base. “We have production and service locations in Europe, the US, China, and India,” says Cattan. “That global footprint is important for OEMs looking for consistent quality and local support in every major market.”

Looking ahead, Bonfiglioli is preparing to launch a new integrated AGV drive solution later this year. “It’s made entirely in Italy – motor, gear, controller, all in one. That gives us total control over quality and design, and helps our customers reduce their supplier base without compromising performance.”

For Bonfiglioli, the future is compact, smart, and collaborative. And as the AMR and logistics sectors continue to demand speed, flexibility and intelligence, it is really gearing up to meet it.

similar news

Italian Specialist Bonfiglioli to Present Electric Drives at LogiMAT