With margins under pressure and labour in short supply, forward thinking logistics service providers are taking a new, radical approach to winning business using flexible automation, writes Jo Bradley (pictured), Business Development Manager at Sparck Technologies.

There is an emerging sea change in the traditional 3PL–client relationship around automation. Whereas a 3PL would normally win a contract first and then possibly install automation if it was thought appropriate for efficient and profitable execution, now some 3PLs are looking to invest in automation first and then pitch their solutions to potential clients.

The risks associated with automation for the 3PL have always been regarded as too high – particularly, with the predominance of short contract lengths. So what’s changed? The catalyst has been the emergence of readily available, low-Capex and highly flexible automation – the likes of intelligent mobile robots and advanced fit-to-size packaging systems.

A typical contract with a client is for around two or three years, and now with so much uncertainty in the economy, clients tend to be looking for shorter rather than longer commitments. That would almost certainly be less than the time required to achieve a positive Return on Investment (RoI) for many traditional forms of automation.

The risk for the 3PL has always been that if the automation is tailored to the needs of a specific client, and that client doesn’t renew – or worse, goes out of business – the 3PL may not achieve as fast an RoI as expected. Even if the client is retained, volumes achieved in existing or renewed contracts may well be lower than planned – positive RoI is delayed, and the equipment may not easily allow for the needs of an additional customer taking up the now spare capacity.

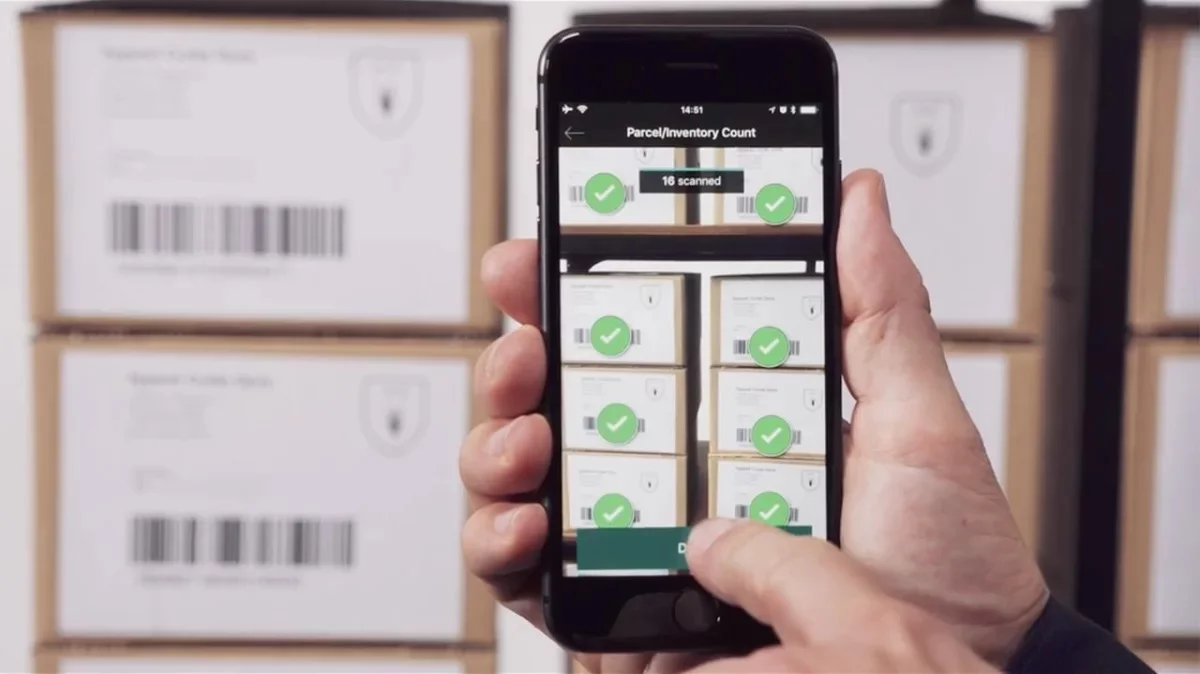

That at least has been the traditional thinking. Now, however, highly flexible automation is changing the dynamics of the warehouse, particularly around ecommerce operations – and this is reshaping how 3PLs can present their service offerings. Autonomous Mobile Robots (AMRs) are transforming order picking processes and within the packing area, a common pain point for both throughput and labour, advanced automated fit-to-size packaging systems are offering scale at peak and flexibility to cater for a wide variety of order profiles – and that can be across several clients.

Automated fit-to-size packaging systems not only offer the efficiencies of high volume throughput, low labour content, improved material use and better transport efficiency that 3PLs and their clients demand, but critically, they also provide the essential flexibility that will future-proof the investment.

Looking at efficiencies, put simply, advanced right-sized packaging systems, such as Sparck Technologies’ CVP Everest and Impack machines, 3D scan the item or items, work out the optimal shape and size of box, and cut, build, seal and label each package at speeds of up to 1,100 packages per hour. Both solutions can have up to three card mills feeding continuous fanfold card of different widths (60cm, 80cm, 100cm for example), which ensures optimal use of card ‘on the fly’, reducing waste and minimising cost. Or in the case of a 3PL, the three card mills could hold individually branded card feeds allowing multiple brands (clients) to be packed by a single machine.

Over the last couple of years Sparck Technologies has analysed some 10 million packages across sectors from the toy industry to multinational contract logistics and fulfilment companies, so we can reasonably claim that our figures are robust. Of course, achievable improvements depend on how efficient the existing arrangements are, but on average box volumes are reduced by up to 50% or more (83% has been recorded) with benefits in more efficient use of costly transport and greater consumer satisfaction – not least through the elimination of void fill.

Meanwhile, average savings in cardboard used can run at up to 30% or better – for one global logistics company the calculations range from 36% on the widest board, to 60% on the narrowest – a saving that goes straight to the bottom line.

On the labour side, with throughputs of up to 500 boxes/hour on the Impack line, or 1,100 on the Everest, anywhere up to 20 manual packing stations can be replaced by one or two line operators: labour which, if you are lucky enough to have, can be redeployed to more rewarding and value-adding tasks. The potential for significant cost reduction is obvious.

So we can demonstrate serious cost-saving efficiencies – what about flexibility? These packaging systems are ‘flexible’ in a number of senses. Firstly they can pack orders for several clients in random sequence (identified by bar code). This can be achieved either with the preprinted branded fanfold card feed, or we can also offer in-line mono or CYMK printing of neutral card on three sides – from a simple ‘This Way Up’ message to QR/AR codes or full colour customer branding.

Therefore, there is no downtime or changeover period as different client’s orders come down the line, and a new customer’s needs can be accommodated literally as soon as the artwork is digitised. Obviously, the ability to construct ‘right size’ boxes from a small number of stock widths obviates the need to carry large numbers of SKUs of preforms (even larger numbers if they are customer-branded) which will in any case be only approximately ‘right size’.

But we can also offer flexibility in a different sense. It may be that even with all the efficiency gains outlined, payback within the life of a contract is not certain. So Sparck Technologies’ packaging systems can be acquired on lease rather than outright purchase. The 3PL can minimise risk from a downturn – or, more happily, lease extra lines if business is booming.

This low-risk approach, which combines verifiable efficiency gains and maximum flexibility, is being adopted by a growing number of leading 3PLs in Germany, The Netherlands and the UK – high profile names, such as CEVA Logistics, Van Eupen and Global Freight Management.

Creative thinking around automation is actively helping 3PLs win new business, and just as importantly, is playing an essential role in delivering enhanced value to existing clients, helping service providers to retain customers, protect margin and extend client contracts.