Wix.com Ltd., a global SaaS platform to create, manage and grow an online presence, today announced the launch of its native shipping solution. Wix has partnered with Shippo, a shipping platform for modern eCommerce, to seamlessly provide Wix business owners with a shipping solution that gives them access to Shippo’s feature-rich shipping capabilities directly from the Wix Dashboard.

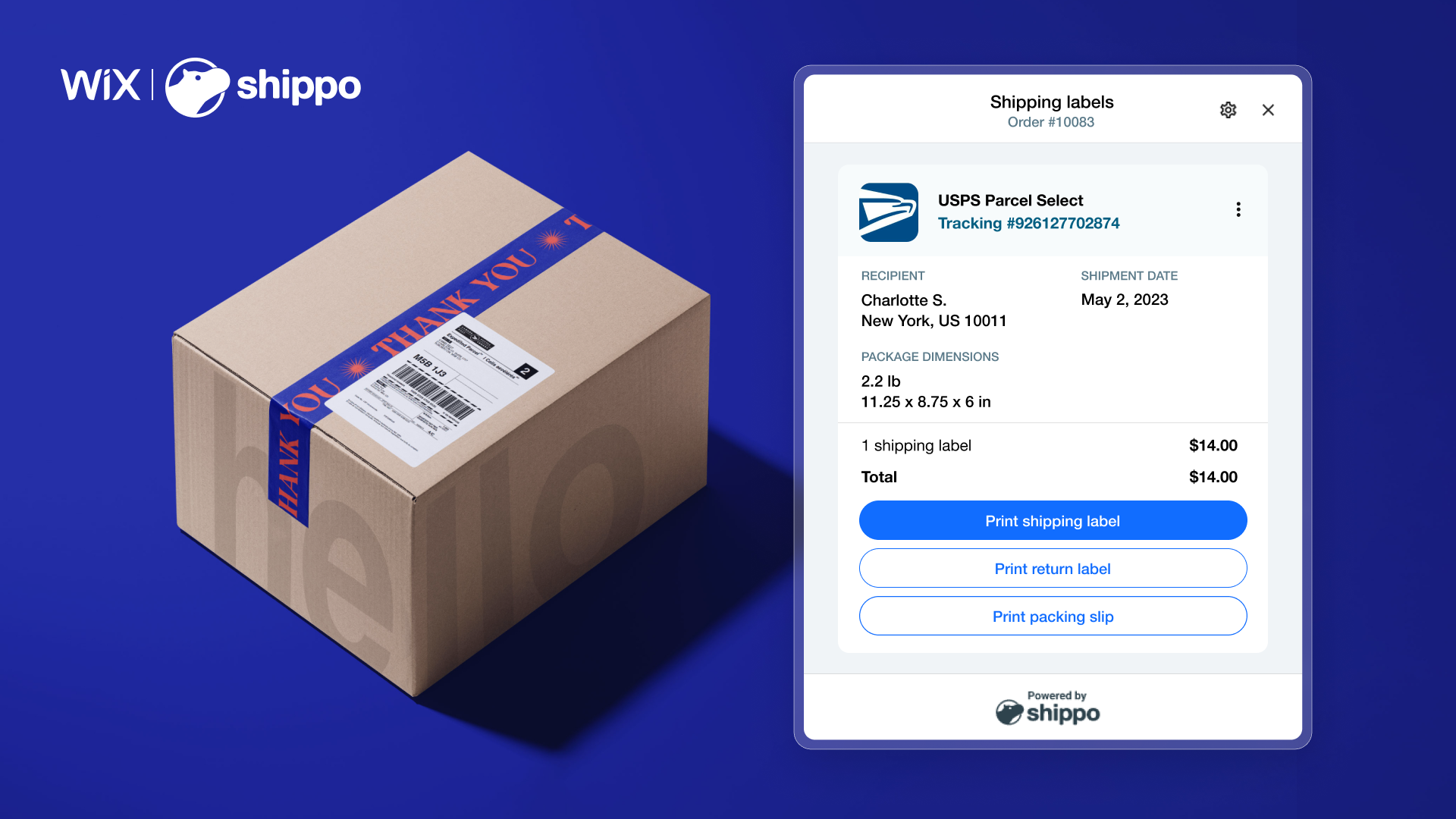

Wix’s comprehensive online platform combined with Shippo’s end-to-end shipping technology provides business owners with the ability to easily and professionally fulfil their eCommerce orders, reducing the complexities they face when fulfilling orders independently. This solution, powered by Shippo’s new Shipping Elements suite of modular embeddable shipping components, gives merchants access to a robust rate engine, tracking and returns flows, and the ability to purchase and print shipping labels without leaving their orders page.

Benefits of Wix Shipping include:

• Fulfilling orders faster: From within the Wix Dashboard, business owners can buy and print shipping labels, as well as print return labels. This removes the need for additional shipping applications, accounts, and fees to fulfil orders without friction.

• Managing inventory and shipping in one place: Users can fulfil orders in the same place they manage products, inventory, and other aspects of their business for a more streamlined process.

• Receiving carrier benefits: Business owners have access to pre-negotiated rates, discounts on top carriers, and flexible shipping options for any shipment volume. Additionally, every region has its own local carriers, ensuring full geographical coverage and a large variety of top-carrier options and preferred shipping rates.

“We are constantly improving our platform, developing advanced tools and partnering with industry leaders, to provide merchants with all the tools they need to successfully run and grow their business directly from our platform. Helping our users get their products to their customers in a cost-efficient and reliable way is mission critical,” said Arik Perez, Head of Wix eCommerce. “Shipping can be a complicated process with many moving parts and with Shippo’s leading shipping solutions, business owners using Wix can be assured that their shipping needs are met, and decrease logistics headaches, all while providing better experiences for their customers, and scaling their sales.”

“Here at Shippo we live and breathe e-commerce shipping, and we’re passionate about sharing our technical capabilities and knowledge with our partners,” said Andreas Lieber, Shippo’s COO. “That’s why teaming up with Wix is such a great fit. With Wix Shipping powered by Shippo, we’re able to make shipping faster, easier, and more affordable for their users. It’s also a testament to the effectiveness of our Shipping Elements offering, which simplifies the process of connecting with e-commerce platforms and fulfilling our mission of building the shipping layer of the internet.”

Wix Shipping powered by Shippo’s Shipping Elements is now available for Wix users based in the US, UK, Canada, and Germany with plans for more geographies in the future.

Founded in 2013, Shippo is the leading shipping platform for modern e-commerce. More than 120,000 businesses, including top e-commerce platforms, marketplaces, warehouses, and brands, trust Shippo to navigate the complexities of shipping and fuel growth. With Shippo’s platform, businesses of all sizes can access 37 global carriers, get real-time shipping rates, print labels, automate international paperwork, track packages, facilitate returns, and more.