Cimcorp is a pioneer in intralogistics solutions, simplifying material flows and improving customers’ profitability by offering innovative and efficient solutions for automation. The company’s high-level technical skills combined with software know-how have created a unique formula for success in grocery retail automation. Through its automated logistics systems, Cimcorp provides its customers with the freedom to focus on their core business and offers them peace of mind.

From field to store within 24 hours

Freshness is a paramount consumer requirement that poses challenges for grocery logistics. With Cimcorp’s solution, grocery retailers have been able to dramatically reduce logistics delivery times from field to store.

“The grocery industry is extremely competitive, as shoppers change consuming habits fast and change stores even faster,” says Kari Miikkulainen, Director of Warehouse & Distribution Industry Sales at Cimcorp. “Today, stores offering the freshest, most seasonal produce win. Our job is to help industry players provide their shoppers with more high-quality fresh produce in less time.”

Optimizing intralogistics can, at its best, halve the time taken for produce to travel from field to store. For example, Cimcorp’s intralogistics solution has revolutionized the order-fulfillment process of the Spanish supermarket giant, Mercadona, enabling the delivery of fresh and seasonal produce to stores within 24 hours. By reducing lead times and optimizing order flows, Mercadona has extended shelf life for its perishable goods, reduced food waste and enhanced the overall customer experience.

Quality is another key criterion for consumers when shopping for groceries. In order picking, speed and precision are decisive for product quality, considering that there is typically a wide assortment of fresh produce articles. Boasting the largest range of groceries in the discount segment, German food retailer, Netto Marken-Discount also automated its fresh produce logistics with Cimcorp.

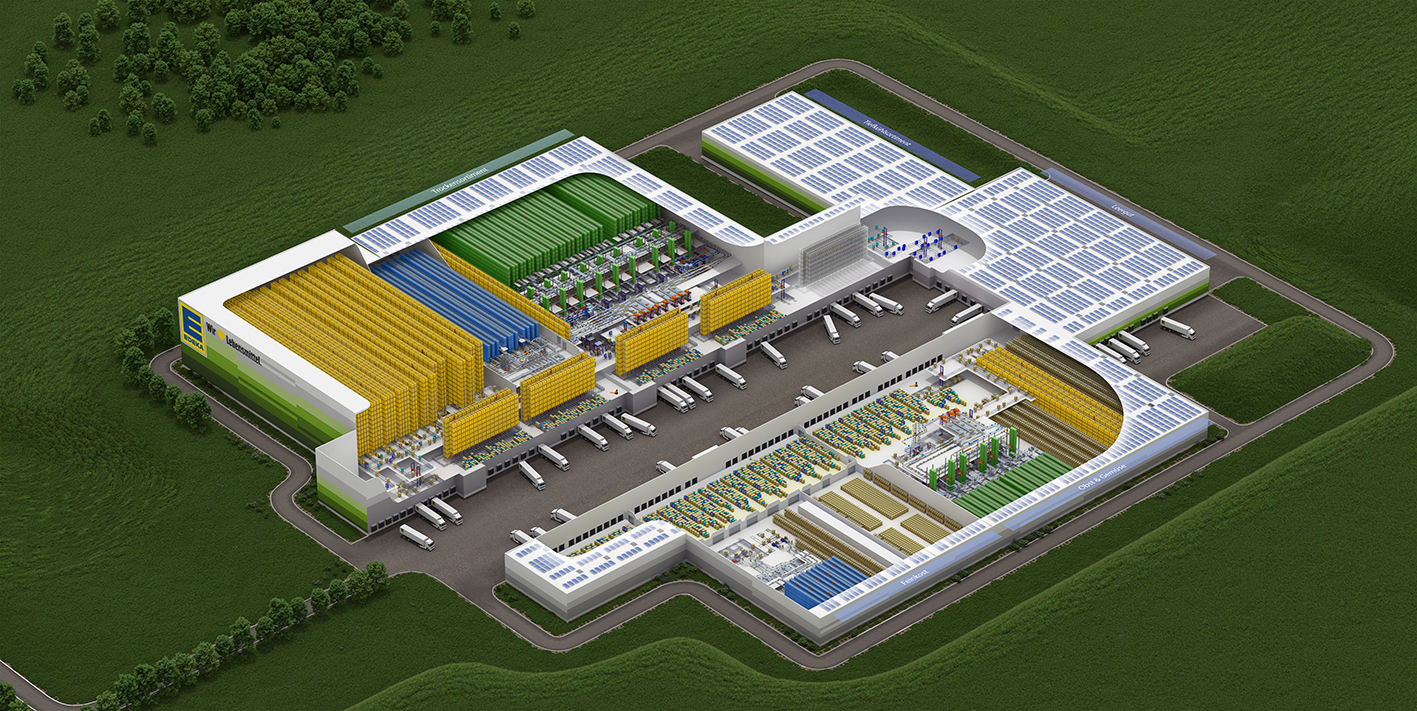

Fresh produce has a limited shelf life and the longer it takes to get to the store, the greater the chance that it will spoil or lose its nutritional value. With Cimcorp’s automation expertise, Edeka Freienbrink – part of the largest German supermarket chain, Edeka Group – delivers fresh produce to its stores within 4-5 hours of receiving orders.

Securing employee safety and wellbeing

Automation can also alleviate ergonomic and labour issues, enabling operations to run in a faster and safer way. As labour availability continues to be a major challenge, employees in manual warehouses need to work harder and faster to fulfill orders accurately and on time. This poses significant ergonomic hazards and risk of injury.

“The order-fulfillment process is automated; we trust our robots with the heavy lifting,” says Miikkulainen. “Trusting automation maximizes the center’s output capacity, increasing the quality and productivity of the staff at work. This collaborative, human-robotics knowledge ensures that everything inside the four walls of the distribution center is optimized, and no orders are ever late.”

At Edeka Freienbrink, the Cimcorp system takes care of the heavy lifting and physical work, allowing Edeka to rely on fewer people at the facility and making it easier to manage. Automation leads to a more pleasant work environment, allowing employees to focus on problem solving and critical thinking.

Mercadona’s approach to the benefits of automation is very employee-centric. The accuracy and quality of picked pallets, as well as shortened lead times, are always reflected through the effect on people. Securing employee safety and avoiding excessive workload are top priorities for the Spanish grocer.

Towards more eco-friendly supply chains

Automation and strategically planned intralogistics can enable businesses to become greener. As a pioneer in intralogistics solutions for grocery retail, Cimcorp is a partner that puts sustainability, social responsibility and governance plans into action. An inventory and supply system that flows smoothly encourages long-term resilience and complies with future requirements for transparency and sustainability, while also reducing carbon footprint and fresh-produce wastage.

In addition to successfully accelerating the intralogistics of customers around the world, Cimcorp has helped many grocers to utilize reusable plastic crates (RPCs). RPCs can help to minimize environmental impact beyond food waste. RPCs can be used thousands of times, replacing cardboard boxes as the method of transport for fresh produce from the farm to the store shelf. For example, Cimcorp has helped Mercadona to match automation and RPCs for excellent results.

Cimcorp’s Warehouse Control System (WCS) helps organize intralogistics and streamline the overall supply chain in a more sustainable way. Through optimizing the loading of delivery vehicles, customers can utilize their vehicle space more efficiently, which leads to fuller trucks and therefore fewer trucks. This means driving fewer kilometers on the road, reducing both CO2 emissions and pollution from exhaust fumes.

read more

Cimcorp to Automate Fresh Food Distribution for Spain’s Mercadona