Lead-acid battery, lithium-ion technology or fuel cell? To operate economically and efficiently, you need to identify the most suitable energy system for your particular transport processes. This decision depends on many factors and therefore requires a high degree of experience. The intralogistics and energy experts of the Hamburg-based intralogistics provider STILL gave a comprehensive overview of the different energy systems during a recent “Energy” webinar and explained the advantages and disadvantages of each system in a clear and hands-on way.

Energy is becoming an increasingly important issue in intralogistics. The European Union aims to have a climate-neutral economy by 2050 at the latest – Germany even wants to achieve this goal much sooner. This means that CO2 emissions must then be avoided as far as possible or stored to the same extent as they are emitted. In order to achieve this goal, the EU Commission and the individual countries are now imposing laws and regulations to oblige everyone to make their contribution. These include increased CO2 taxes, expensive emission certificates and a complete ban on internal combustion engines, which will make electric drives mandatory for all vehicles by 2030 at the latest.

In addition, consumers are also becoming more sensitive with regard to the climate neutrality of services and products. For this reason, companies are also increasingly looking to ensure that their supply chains meet sustainability requirements. Suppliers, for instance, must provide certificates on the origin of raw materials, production conditions and the CO2 footprint. A good ecological balance sheet is thus increasingly becoming a competitive advantage.

Looking for the right energy system

One thing is true throughout Europe: Energy is precious, it is becoming ever more precious and therefore the consumption and use of energy must be managed intelligently. In intralogistics, this begins with the selection of the appropriate energy system for the drive of industrial trucks. The current choices are lead-acid batteries, lithium-ion technology, or fuel cell systems. But no matter which system is chosen, this decision will have an impact. On the infrastructure of warehouses and production sites, on the choice of transport systems, on operating costs and ultimately on the size of the investment.

“Each of these energy systems has its own special features and requires certain prerequisites in handling,” explained Dyrk Draenkow, product manager for energy systems, during the webinar. To come to a sustainable and economically efficient decision, the overall picture must be considered: transport processes, the desired handling performance, the type of vehicles and, of course, the infrastructure of the warehouse.

Suitability criteria

According to Björn Grünke, also product manager for energy systems, this leads to five criteria that can be used to identify systems that are optimally suited to the respective requirements: vehicle availability, infrastructure aspects, acquisition and operating costs, as well as sustainability. According to the expert, lead-acid batteries have a rather mediocre overall result in this analysis. While their performance in terms of vehicle availability is mediocre, they are not at all convincing in terms of infrastructure due to their high storage space requirements.

On the other hand, they come out on top when it comes to investment costs. Compared to all known energy systems, the purchase price of lead-acid batteries is very low at around 150 euros per kilowatt hour. However, this bonus is offset by the system’s only moderately efficient operating costs. And when it comes to sustainability, this energy system can only partially convince the STILL experts.

“This technology is exhausted. No further developments towards significantly shorter charging times or higher power density are to be expected,” said Draenkow and added: “However, if we disregard the limitations described, this type of battery will remain a reliable and very useful energy system for the next few years. It is especially suitable for users who have only a few vehicles and only a few working hours to deal with.”

Lithium-ion technology

Li-ion batteries can be interim charged at any time – and that within a very short time, without damaging the battery or shortening its service life. This makes it possible to use the vehicle flexibly, around the clock, without having to change the battery: lithium-ion technology thus ensures maximum availability even in multi-shift operation. And as far as charging time is concerned: in most cases, as experience has shown us, one hour of charging means up to three hours of driving.

Moreover, this energy system places very few demands on the infrastructure. When it comes to investment costs, the situation is somewhat different: Lithium-ion batteries still have a higher purchase price than lead-acid batteries. It is about two to three times as high.

“However, lithium-ion batteries have at least twice the service life with the same capacity. If you look at the general price development of lithium-ion cells since 2010, the trend is clear: They are getting cheaper and cheaper,” says Grünke. The system also stands out when it comes to sustainability. Charging and control options for increasing efficiency are constantly being developed further, while at the same time the acquisition costs for the system are being reduced.

Fuel cell systems

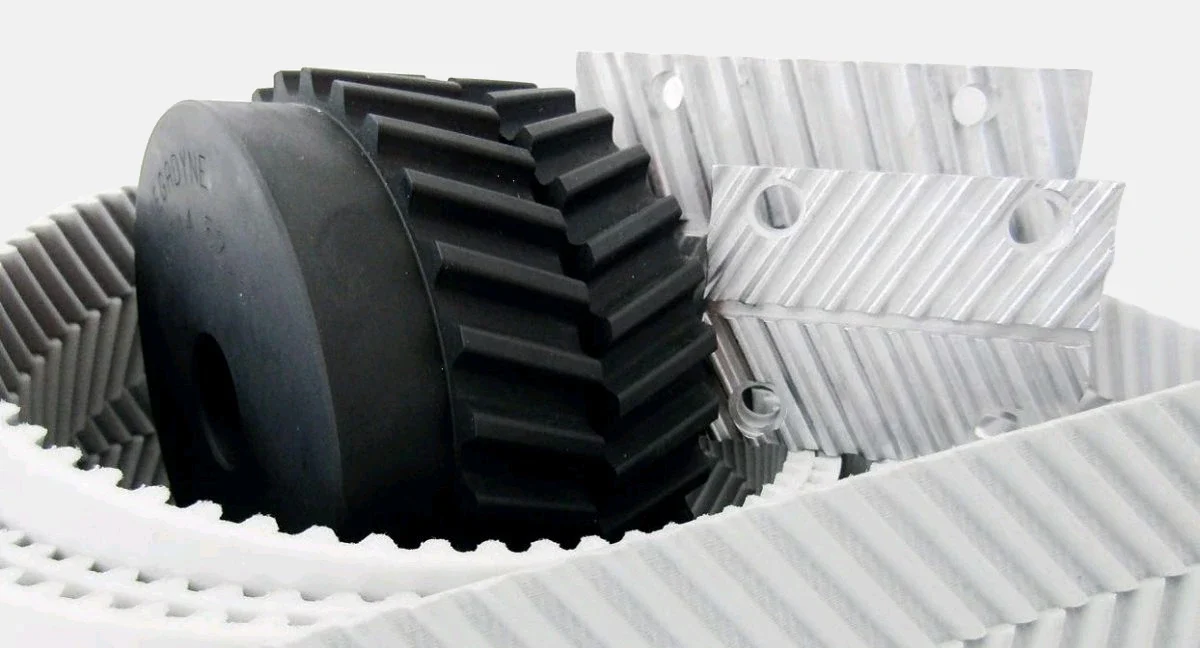

What is special about this energy system is that the electricity is generated within the vehicle and no longer comes out of the socket. Draenkow says: “When we talk about a fuel cell in intralogistics, we mean a so-called battery replacement module. This corresponds to a specific battery trough in terms of size, weight and shape. This means that an existing lead-acid or lithium-ion battery can be replaced one-to-one with this module. All the components necessary for a fuel cell are assembled in such a module.”

This includes the fuel cell itself, the so-called stacks. These convert the energy stored in hydrogen into electrical energy. This energy is then used to charge the integrated Li-ion battery. This is needed to supply the vehicle with continuous power. Also part of the system is a high-pressure hydrogen tank, including a fuelling nozzle and other components. It is an all-in-one system.

Since the system does not have to be charged but refuelled, there is no downtime at chargers or sockets. After only 2-3 minutes at the hydrogen pump, the vehicle is available again at full capacity. This creates maximum flexibility in terms of operating times and allows for tough demands and/or multi-shift operation without restrictions. Experience shows that a tank filling can allow up to eight hours of use, depending on the vehicle type and use.

However, the hydrogen required must be delivered by tanker truck. Or you can make yourself completely independent and produce the hydrogen yourself with your own electrolyser on the premises. This, however, requires additional electricity. If you want to be sure not to emit any CO2 in the process, you can produce the “green” energy yourself: by wind turbine and or photovoltaics.

Of course, this involves a certain amount of effort, which is why fuel cell technology can only be rated as moderately suitable in terms of the infrastructure criterion. And with regard to investment costs: On the one hand, a “fuel cell ready” vehicle must be purchased new ex works. On the other hand, costs arise for the acquisition of the suitable fuel cell system. These are currently priced at a factor of 4-5 of a lead-acid battery. And to create the necessary infrastructure still requires high investments, so that it is currently hardly possible to profitably use fuel cells for vehicles.

However, funding programmes at the national and European level are helping to make this business case “green” in economic terms in the future. Subsidies are available both for the equipment of the vehicles and for the infrastructure. Draenkow comments: “Basically, what will apply to the future of fuel cells is the economies of scale: the more hydrogen consumers there are on the premises, the faster the costs per kilogram of hydrogen can be reduced.”

Summary

The efficiency of an energy system always depends on the particular application. Unfortunately, there is no single system for all applications. Guidance in this very confusing situation is provided by the intralogistics and energy experts of the Hamburg-based intralogistics supplier STILL – for example during the energy webinar, but they are also available anytime to offer advice and support to companies that are about to make an investment decision.