ABM will present complete drive solutions for a wide range of intralogistics applications at the upcoming LogiMAT in Stuttgart (19–21 March) in Hall 3 at Booth 3B15. The system supplier tailors the drive solutions in close cooperation with the customer to his unique application and requirements – while maintaining a strong focus on ensuring sustainability and efficiency of the proposed drive package.

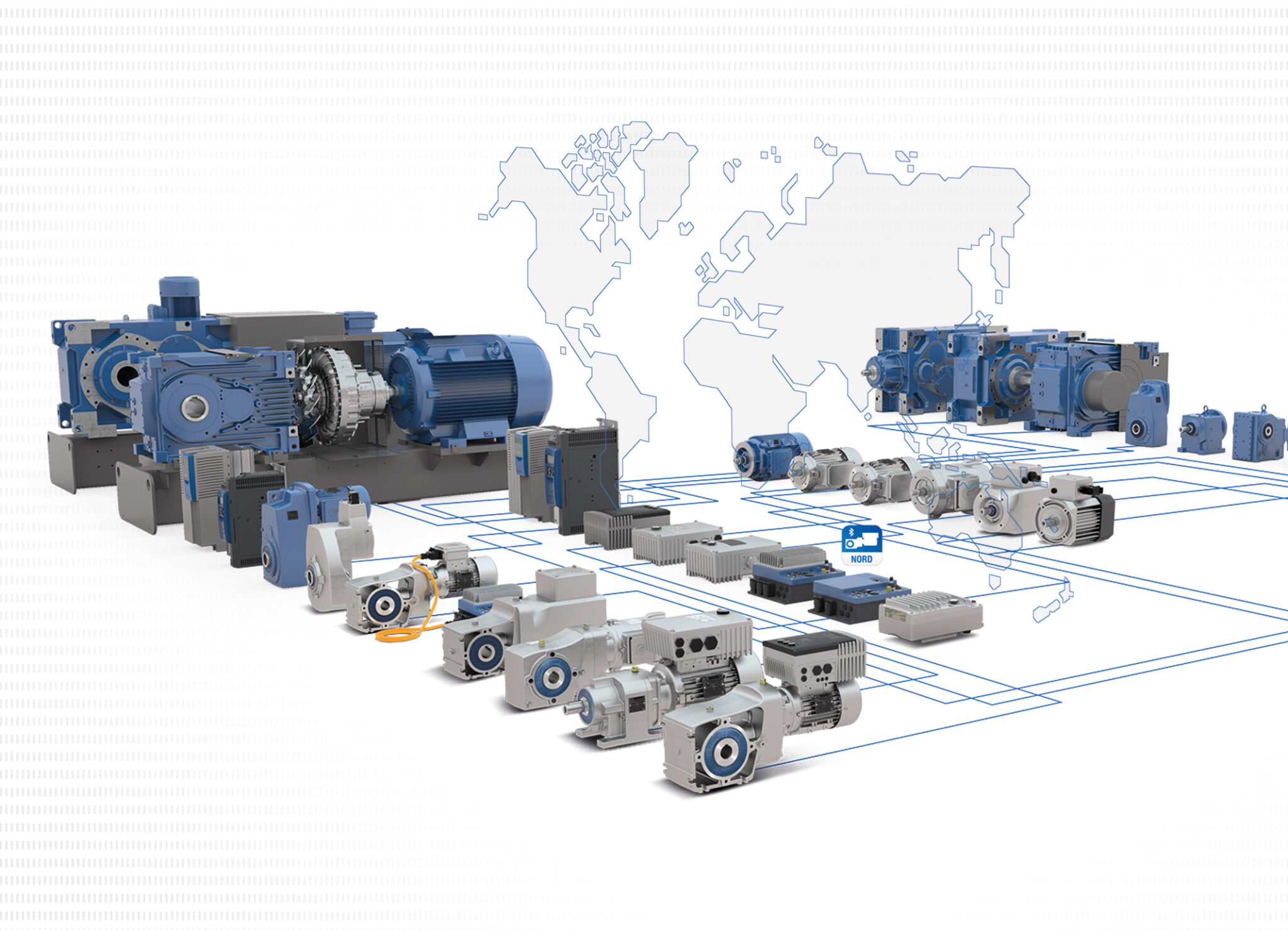

As a full-service provider, ABM develops and manufactures drive systems for stationary and mobile applications in all areas of intralogistics. In electric buses or trucks they are used, for example, for auxiliary units such as hydraulic pumps, air compressors and cooling fans. They are also installed in pallet trucks, forklift trucks and automated guided vehicles (AGVs) as well as in container and pallet conveyors, cranes and industrial doors. The system solutions consist of motors, gearboxes, brakes and inverters – selectively for mains or battery power supply.

Drive Components for Traction, Lifting and Steering

ABM offers all drive solutions for driving, lifting and steering of forklift trucks as a single source. The motors, gearboxes and inverters comply with strict environmental requirements, are safe and are extremely responsive for precise movements even at low speeds. One of the available drive options are the two stage bevel gearbox units of the series TDB. These drive units come with plug-and-play capability for easy integration and are both powerful and energy-efficient. They offer high power densities at optimum efficiencies. The compact series is available with manual or individual steering as well as with integrated electric steering drive.

The drive specialist will present the TDH series electric-steering hub-wheel drive units with inverters for AGVs, pallet jacks, cleaning machines, industrial trucks or track-bound vehicles. These units are compact, robust and capable of handling high static and dynamic wheel loads. For the motor control specific sensors that record speed, rotor position and temperature are included.

Driven with High Energy Efficiency

The wide product range includes induction motors as well as the sustainable and high-efficiency Sinochron motors. Because Sinochron motors already meet the requirements of premium energy efficiency class IE5, users do not have to worry about compliance with legal regulations. The synchronous motor has a compact design and can easily be integrated into systems. With the unique feature sensorless control, the inverter calculates the rotor speed and the instantaneous rotor angle from electrical feedback. With this data, the currents for torque generation can be fed precisely to the motor. The motor can be optimally controlled over a wide speed range with a high starting torque – without the need for expensive sensors.

The comprehensive product range also contains helical gearboxes with torques from 30 to 2000 Nm, parallel shaft gearboxes with 50 to 2300 Nm and angular gearboxes with 60 to 450 Nm. They can be supplied with flanges, solid shafts or hollow shafts. Also available are brakes and sensors.

Via an intelligent modular system, the provider can adapt the various gearbox configurations to the respective application and rapidly deliver a drive solution with high cost efficiency with regard to functionality and efficiency. ABM also offers industry-tailored concepts. For special applications, ABM can also develop completely new system solutions as partners in close cooperation with customers.

Integrated Drive System for Accumulation Roller Conveyors

One innovation example is the highly integrated drive system for accumulation roller conveyors. During development focus was placed on compactness, maximum efficiency and cost. Efficient and dynamic motors are installed as direct drives for small loads. For higher loads – such as in pallet conveyors – the drives can be combined with angular, helical or parallel shaft gearboxes. Added to that is an inverter series designed especially for intralogistics applications. This series is available in three sizes with power outputs of up to 2.2 kW and a high overload capacity of 250 per cent. With the series, ABM covers all common applications in container and pallet conveyor systems. And because most drives in intralogistics only operate at part load, the Sinochron motor with sensorless control are the perfect match.

Externally Excited Motor

An externally excited motor for e-mobility, which is still under development at ABM, is also sustainable and efficient. At its booth, ABM will offer an early look at the innovation, which is completely free of rare earth magnets. The good field weakening behaviour mirrors the torque/speed requirements for traction drives, because they can be controlled more efficient and variable. ABM supplies drive solutions for intralogistics as a single source. The customer receives a tailored, installation-optimized, highly energy-efficient solution for the given application. With this, ABM continues to pursue its goal of delivering high-quality, reliable drive solutions and as a partner supporting its customers with engineering and manufacturing expertise.

Read more here:

Drive Specialist ABM Greiffenberger to Display at LogiMAT