The September 2025 issue of Logistics Business magazine is packed with insights into the technologies, strategies and solutions reshaping global supply chains. A strong focus is placed on artificial intelligence and automation, with Samsara showcasing its latest driver safety and fleet optimisation tech from the Beyond event in San Diego. Further AI coverage includes interviews with Coupa’s international head and Transporeon, both exploring how data-driven platforms are transforming spend management and freight visibility.

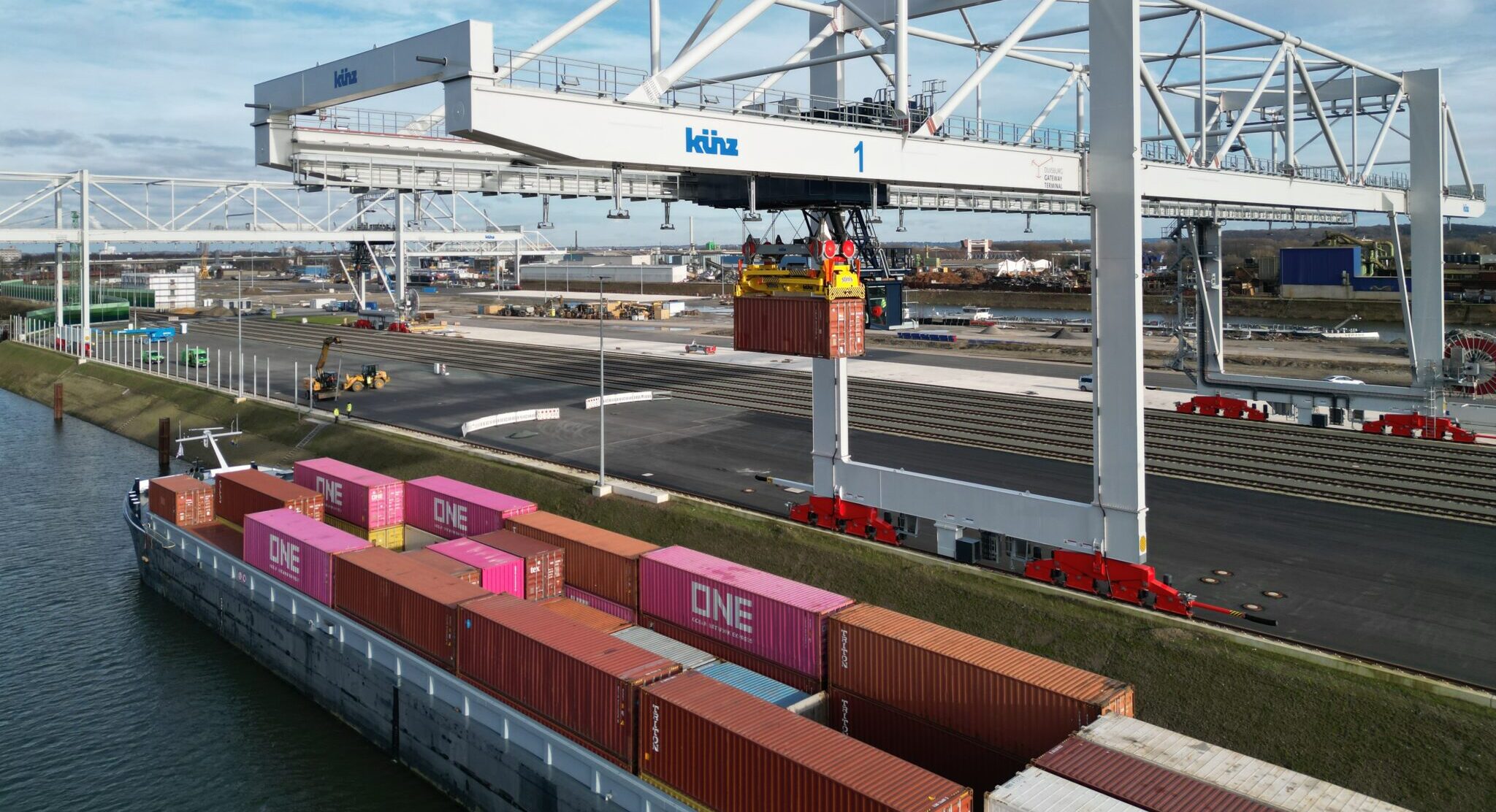

Supply chain strategy takes centre stage in an exclusive interview with Siemens’ Alexander Tschentscher, who advocates a shift from reactive resilience to strategic robustness. Meanwhile, Ewals Cargo Care shares how its “warehouse on wheels” model and modal shift approach are reducing emissions while expanding operations across Europe. Port innovation is also in the spotlight as PEMA President Achim Dries outlines how ports and terminals are digitising, automating, and gradually weaning off diesel in favour of electrification and smart power management.

Inside the warehouse, automation continues to surge. Hyster discusses its big-truck innovations at TOC Europe, and a new automated distribution centre in Coventry demonstrates what’s possible in modern DC design. Case studies from CLAAS, Axfood, and others show how internal logistics and fulfilment strategies are evolving to meet increasingly complex demands.

Sustainability is another dominant theme throughout this edition. The magazine looks at how plastic pallets, automated packaging and green fuels—such as HVO used by DHL’s Formula 1 fleet—are cutting carbon without compromising performance. E-commerce brands like Bathroom Mountain and major supply chain software providers such as Soloplan and IFS also feature prominently, revealing how automation, AI and smart planning tools are supporting faster, leaner, and more resilient operations.

From warehouse doors to multimodal transport, and from predictive software to people-centric AI, this issue offers a comprehensive and engaging snapshot of the forces shaping logistics in 2025.