Effective October 15th, Peter Edelmann has been appointed as the new CEO of leading intralogistics company SSI Schaefer. In this role, Edelmann (pictured, right) takes over from Steffen Bersch, who has led the company for the past three and a half years.

Peter Edelmann has many years of management experience, including over twenty years with the Voith Group, most recently as a member of the Group’s Management Board. Furthermore, Peter Edelmann has managed the companies Kaefer Isoliertechnik in Bremen and B&C Industrieholding in Vienna as CEO. In addition, he holds various supervisory and advisory board mandates.

As a further member of the two-member Group Executive Board, Olaf Hedden has been appointed CFO. He will also take over on October 15, 2023, succeeding Bruno Krauss.

Olaf Hedden has many years of management experience. He began his career at Metallgesellschaft and later worked for several years at Rheinmetall, his most recent role was as CFO of Rheinmetall Automotive AG. In addition, he is also familiar with medium-sized structures through his work as a Spokesman of the Executive Board of Läpple AG.

Dr. Kay Mayland, Chairman of the Advisory Board of the SSI Schaefer Group, comments: “The Advisory Board and shareholders of SSI Schaefer Group are convinced that in Peter Edelmann and Olaf Hedden, they have found a very experienced team for the overall management of the SSI Schaefer Group. With their many years of expertise with industrial companies of different sizes and sectors, they will give the company new impetus. At the same time, we would like to thank Steffen Bersch and Bruno Krauss for the work they have done and wish them all the best for the future, both professionally and privately.”

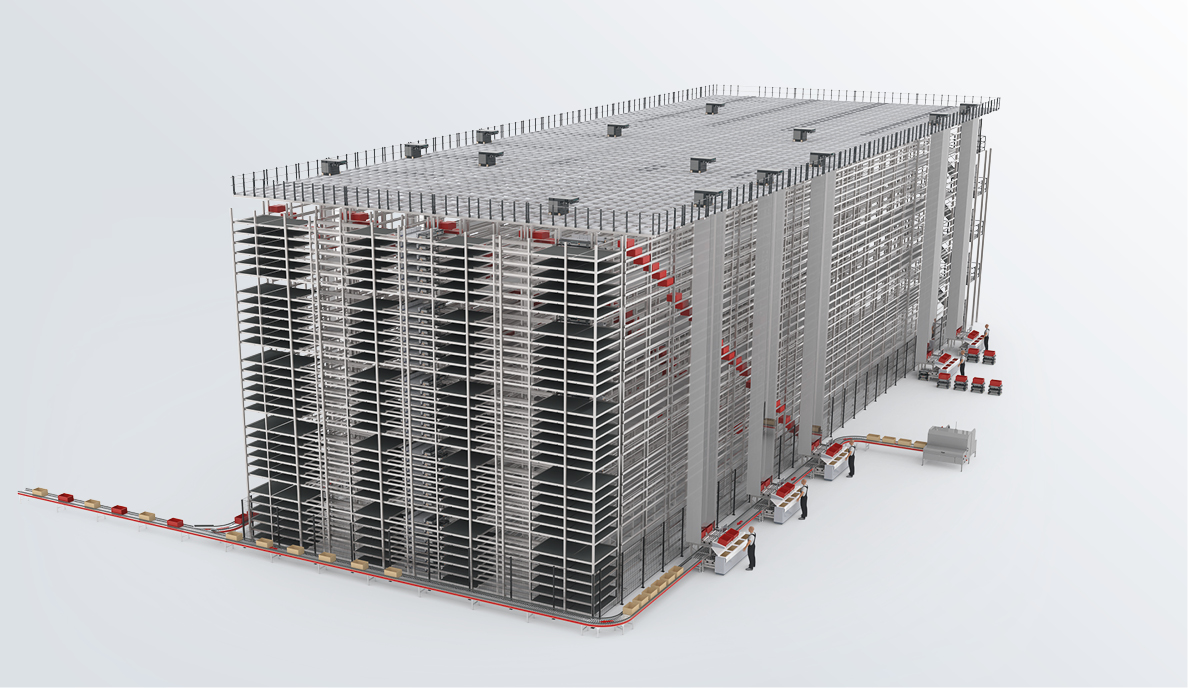

The SSI Schaefer Group is a leading global solution provider for all areas of intralogistics. With innovative technologies and software, the company empowers customers to increase the efficiency and sustainability of their storage, picking, and transport processes. SSI Schaefer offers small and medium-sized enterprises, as well as large companies, cost-effective material handling solutions with industry expertise from a single source. From fully automated warehouses with tailored service and maintenance packages, to robotics and automated guided vehicles, to manual and semi-automatic systems such as workstations, racks, and containers, the company offers a complete solution. SSI Schaefer has also become one of the largest vendors of software for internal material flow. Its comprehensive software portfolio handles everything from warehouse management to material flow control. With state-of-the-art real-time analysis, intelligent data processing and optimization algorithms, it offers every possible option for integrated, sustainable resource management.

SSI Schaefer employs around 10,000 people at its international headquarters in Neunkirchen (Germany) and globally in more than 70 operating companies and seven production facilities on six continents.