Dexory has secured additional investment with Schenker Ventures, the corporate investment arm of DB Schenker, strengthening further their position in the market. This investment will allow greater focus on introducing the DexoryView solution across Europe and into the US in the coming months.

Following the recent $19m Series A funding announcement in June, this partnership continues to strengthen Dexory’s leading position on providing real time visibility across the supply chain.

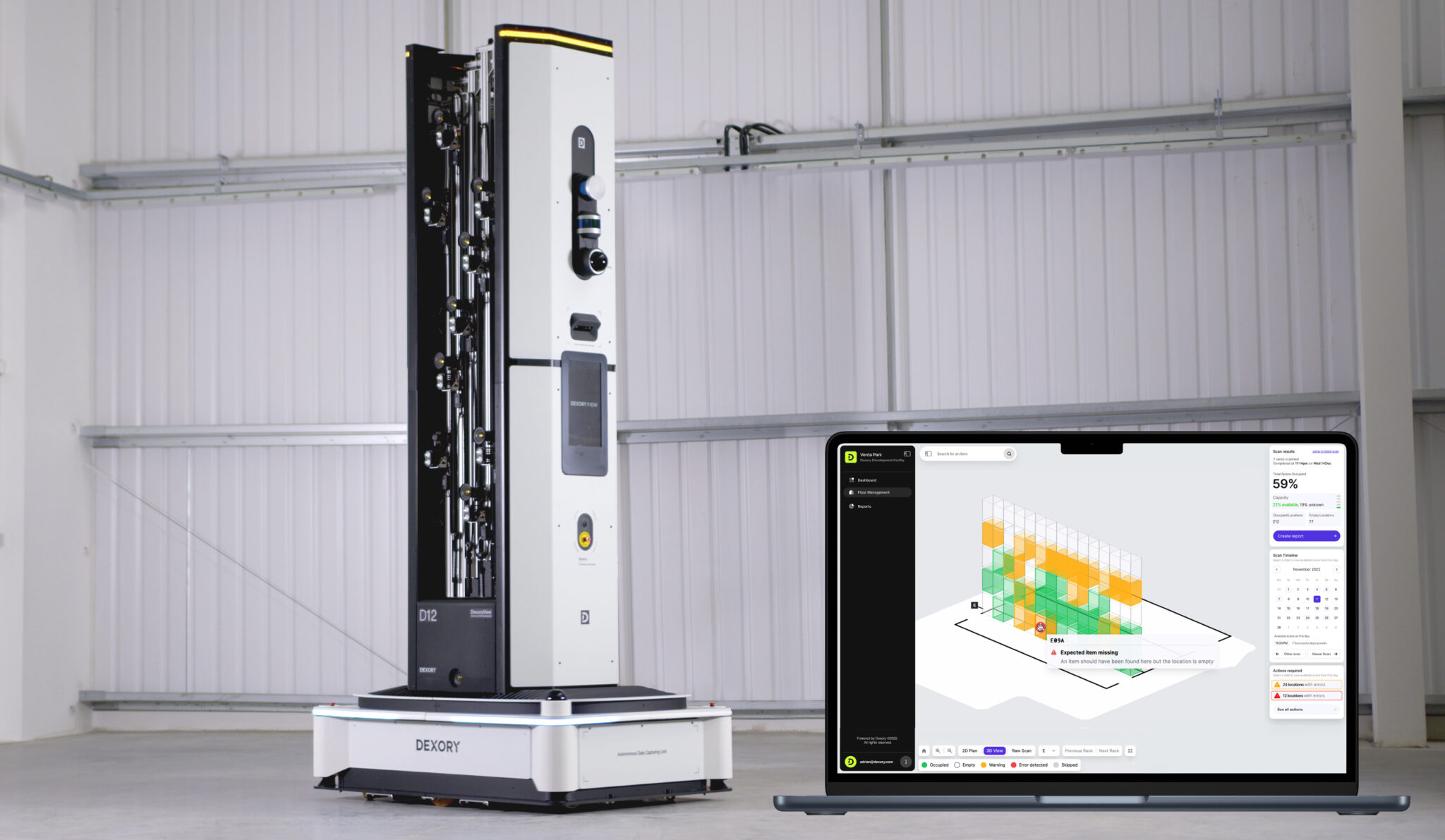

Dexory’s solution addresses the urgent need for improved visibility, better space utilisation and increased efficiency in warehouse operations around the world. Dexory brings together autonomous robots, capable of capturing rich image and sensor data from across a warehouse, with powerful analytics and insights. This powerful combination provides comprehensive visibility across individual warehouses of any size, as well as connecting sites across the global supply chain through Dexory’s digital platform, DexoryView.

For warehouse operators, guaranteeing flawless ‘on-time, every time’ order fulfilment is paramount to satisfying the expectations of today’s consumers. “Technology that operates autonomously, provides real-time insights, possesses intuitive interfaces, and seamlessly integrates can lead to a revolutionary transformation in the day-to-day efficiency, productivity and precision of warehouse operations”, says Andrei Danescu, CEO and Co-founder of Dexory. “I’m delighted DB Schenker shares our vision for full visibility across supply chains and have great confidence in our technology, ambitions and growth plans. Their industry expertise will help us grow into new territories and maximise the capabilities of the tech while bringing fantastic value to their sites, a great partnership for both.”

DexoryView, a one of a kind platform, conducts comprehensive warehouse scans within a few hours – a 100 times faster than human efforts and other inventory collection technologies. Moreover, DexoryView serves as a digital replica of the physical warehouse, nurturing not only management but also performance optimisation. This innovative feature empowers the software to simulate, optimise, and forecast future scenarios, freeing warehouse colleagues to engage in more complex tasks.

“The potential and evident success of Dexory’s technology within the global logistics landscape in a short space of time is impressive. Dexory has engineered a solution that not only boasts seamlessness and user-friendliness, but also provides a remarkable depth and speed of inventory data collections setting Dexory apart, enabling efficient and accurate insight.” says Paulina Banszerus, Head of Venture Capital, Schenker Ventures.

The strong execution-driven team behind the vision for DexoryView goes beyond inventory management, the technology’s visualisation is impressive, whilst being scalable in the future. And that’s what makes Dexory a great fit to our innovative portfolio. We’re really pleased to be part of Dexory’s exciting future.”

With ongoing conversations to partner with DB Schenker in the various territories, Dexory aims to continue to embed accurate real-time data into its customers’ supply chains worldwide, making it the new standard for the warehouse of the future.