This is the time of year when the majority of online retailers are going through their peak sales period in the run up to Christmas. During the pandemic and lockdown period almost every business with an ecommerce dimension saw sales peaks that were higher than anything they have ever encountered. And despite the fact the pandemic is probably behind us, growth in online sales have continued to soar. In any event, with events such as Halloween and Black Friday having driven sales this year, it is not hard to foresee that demand for online items will continue in the run-up to the festive season.

To cope with this, advanced preparation and planning done beforehand will pay off. The systems and procedures you have put in place to handle significantly increased seasonal volumes should mean that even with temporary hired-in resource, things will still go relatively smoothly. Or will they?

Even before they experienced business during the pandemic, most online resellers could cite at least one experience of underestimating the impact of the festive season. And in order not to repeat that, a common practice is to hire in agency staff at a premium to help with the increased workload. On Christmas Eve, all being well, they can sit back and breathe a sigh of relief, knowing they have just about coped, once again.

Extra sales at Christmas

And it is easy to see why, with the extra sales and profits potentially generated at Christmas, the short-term cost of the labour involved is easily justified. However, cost aside, using temporary labour at any time can bring problems. With greater awareness of the consequences of illness to others, staff are likely to take time off if they suffer from this year’s flu or another bout of Covid. That will inevitably put pressure on your existing operations but recruiting temporary replacements or adding short-term capacity over the peak season may not be easy.

Even if it is possible to recruit effectively, the main problem with temporary employees is user unfamiliarity. With even the best designed and implemented systems there is a minimum level of training needed for temporary staff to be able to function, even at a basic level. New staff will be well short of the experience and knowledge of regular staff, no matter how well you train them. They will not know the environment, the product, or the processes. So inevitably they will be less productive, absorb more supervisor time, and generate more errors which require correction and incur time and cost. They may also cost you a few lost sales, and some unwanted customer issues.

Minimise labour

So, is there a solution to this? Is it possible to minimise the requirement for additional labour in the Christmas period and still meet order fulfilment targets? Well yes, there is, and it seems odd that many companies would rather have a heavy financial outlay on extra staff at Christmas than deploy an IT system that could lessen or potentially even eradicate the need for those staff.

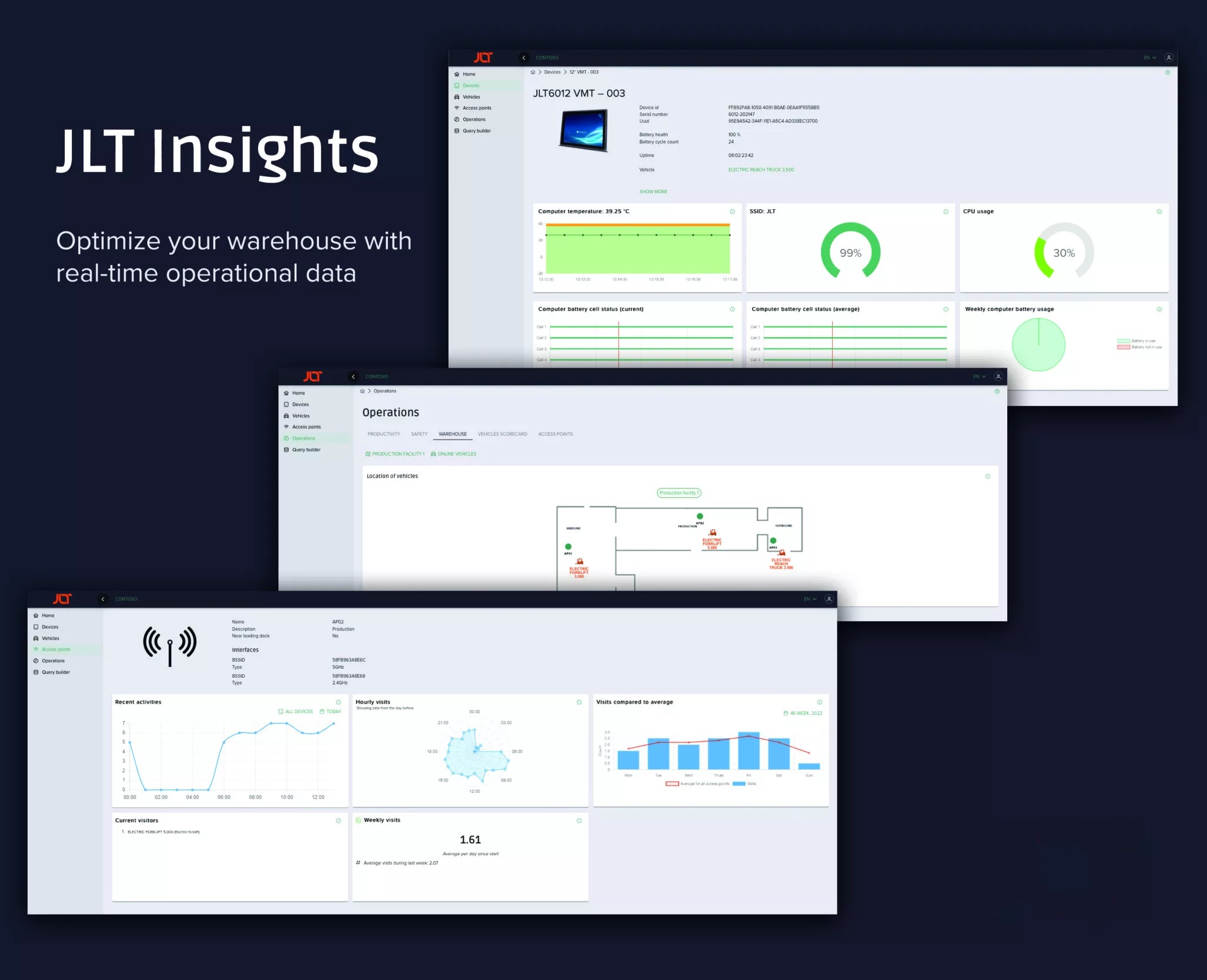

The die is cast for this year, no doubt, but that does not mean things cannot be improved for the future. While some extra cost is always likely there are many ways that deploying the right IT system, particularly a warehouse management system (WMS), can help. This would not only reduce your seasonal expense, but also minimise your costs and boost productivity all year round.

To paraphrase a well-known expression: “A WMS is not just for Christmas.” Not only will it help you manage workloads and reduce excess labour costs at Christmas, it will bring joy all year round! A WMS is designed to manage your physical stock with optimum efficiency by using simple, efficient, and secure processes for all activities from receipt through to despatch. As these are largely system driven which will reduce reliance on staff knowledge, a particular benefit when using temporary labour.

A WMS will ensure that all the information you need about received goods is correctly recorded. It will then automatically instruct putaway to a system generated location, removing the need for staff to know where product is normally stored. When you receive an order, it will direct your pickers to the correct location to find the stock, taking into account any date or FIFO (first-in-first-out) rotation. It will then manage your pack and despatch process, ensuring you deliver the right product and quantity.

Accuracy, efficiency, productivity, and discipline

The benefits of using a WMS – accuracy, efficiency, productivity, and discipline – are magnified when you use the system in real-time with a dedicated app for handheld devices. This allows everything you do to be recorded in real-time, making your stock data accurate to the minute. It also means you can build in as much barcode verification as you need, trapping errors immediately and ensuring the complete accuracy of everything you receive, pick and despatch.

Having a WMS gives you a solid foundation of operational ‘best practice’ which can deliver even greater benefits at your seasonal peak. When you need extra staff, equipping them with an inexpensive handheld device reduces their training needs, so they can be effective almost immediately. As their work is system-directed and verified by real-time scanning, errors and supervisor intervention are cut to a minimum, allowing permanent staff to focus on their own roles.

To save the punchline to the end, the best part of this is the cost. A WMS like ProSKU WMS Cloud – which is available as software-as-a-service (SaaS) and paid for monthly – needs little cost justification for the normal benefits it can provide. It will make your operation lean, efficient and competitive all year long. That will be a benefit to you every year when sales peaks are likely to be significantly higher than normal. When you consider the high (and recurring) cost of temporary seasonal labour, and how using a WMS could lessen this, the investment becomes positively insignificant.