Renovotec, the UK’s fastest-growing rugged hardware, software and services provider for supply chain companies is launching a rental campaign for the latest Epson Colorworks C6000 and C6500 Series custom label printers, targeting manufacturing and logistics users, Renovotec announced today. Epson Colorworks are highly flexible, custom printers, capable of printing one-stage colour labels on demand, in user-defined quantities and designs – slashing print time and label inventory costs say Renovotec.

The Colorworks C6000 printer delivers up to 4-inch print widths and the C6500 up to 8 inches. Both printers improve inventory management and product identification to keep supply chains connected and running smoothly.

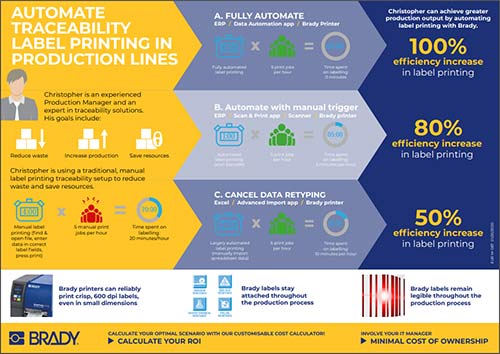

They improve traceability with colour coding, by ensuring that the right products are directed to the right place; reduce supply chain errors, using colour to make labels easier to track, avoiding mistakes; and improve the cost-efficiency of the user’s label production by reducing waste and eliminating the cost of pre-printed labels, according to the manufacturer.

In addition to generic 3PL, logistics and manufacturing companies, target supply chain users for Epson Colorworks printers include retail, healthcare and pharmaceutical and food and catering companies.

Commenting on Renovotec’s decision to launch sales and rental offers for Epson Colorworks products, managing director Richard Gilliard says: “We scour the market to identify best-in-class products and technologies for our supply chain customers, then try to make them as cost-affordable as possible with rental and other options. This latest Epson colour printer technology is ideal for today’s e-commerce marketplace, where speed and flexibility are essential.”