Peak season is a chaotic and profitable time for the majority of retailers and wider value chain. Websites and ecommerce engines need to be fully functioning, able to accept orders and fulfil deliveries – and warehouses and fulfilment centres need to be ready to meet customers’ delivery needs fast. Alongside this, last mile delivery operators need to ensure they have the right processes and systems in place to ship goods on time. In contrast, instore retail must make sure that its warehouses are operationally capable of picking, packing and sending goods to stores in time for shoppers to buy their products over the festive season.

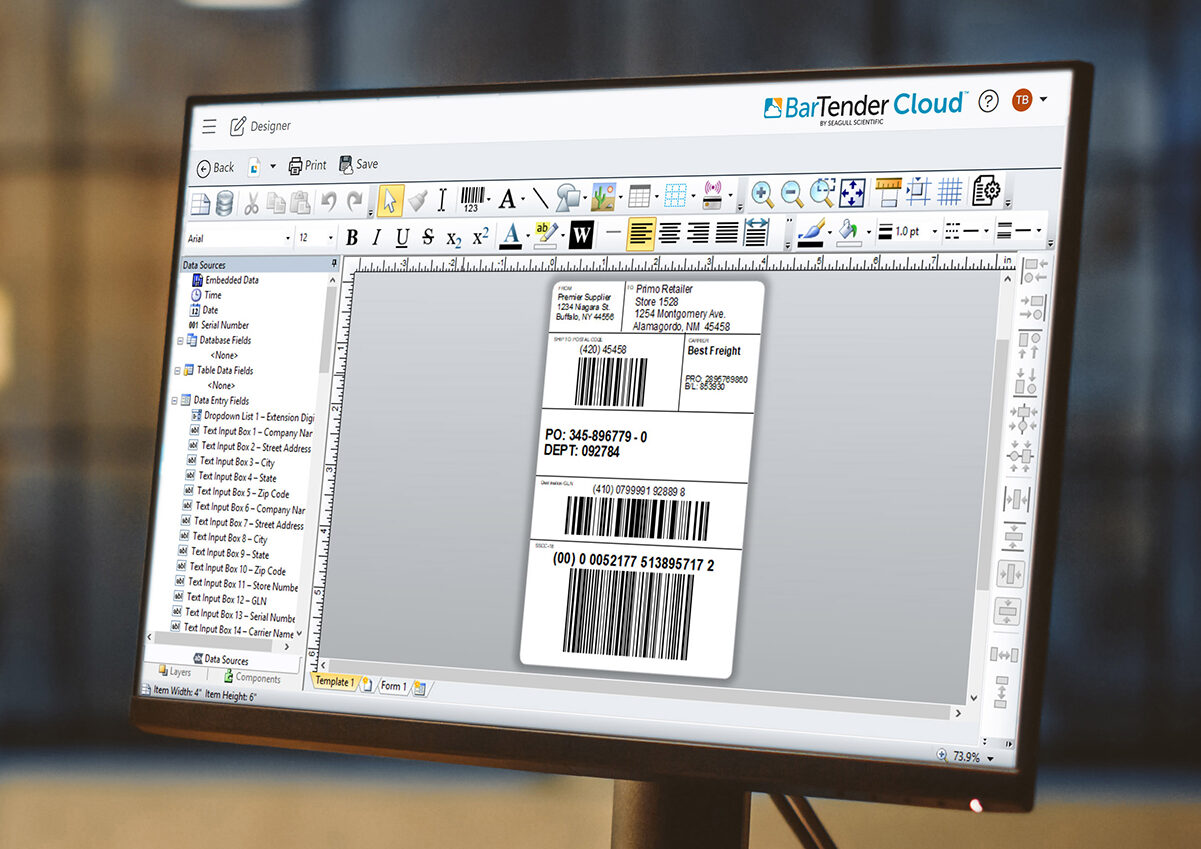

Therefore, for many retailers, third-party logistics operators, warehouses and last mile shipment providers, organising logistics operations effectively with packaging labelling forms a crucial part of their success through and beyond the peak season. Its value, as part of the process, is understated. Jay Kim, Managing Director BIXOLON Europe GmbH explains the important role of using linerless mobile printers to print labels that can be used to organise warehouse operations, support with last mile delivery, and communicate with consumers.

How mobility is refining warehouse operations

Within many warehouse and fulfilment centres there are often stations placed around the distribution centre where printing takes place. This is because many sites and their operational processes have been designed for stationary label printers. While traditionally effective at printing labels, it means processes were designed around the location of printers – meaning that warehouses and staff duties were created with this in mind. It is not uncommon, for example, to see printing stations that have parcels taken to them by warehouse staff, to have labels printed and stuck onto goods. In many instances, labels printed come with liners too. This is problematic because when the liner is removed from the label – often a backing – it needs to be disposed of correctly in additional bins.

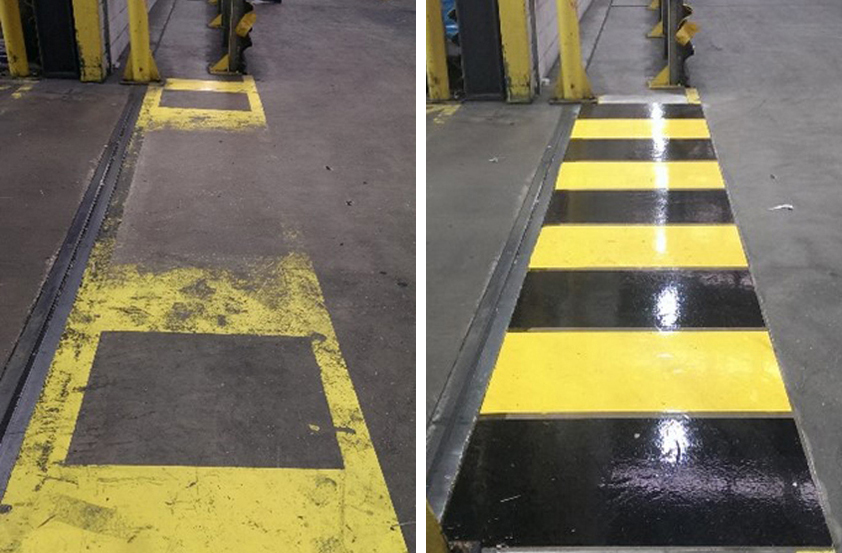

These bins take up a lot of space and liners can end up on the floor by accident, causing health and safety slip hazards. This becomes important to review across the supply chain too. When you consider some ecommerce retailers are shipping hundreds or thousands of goods daily, and many last mile delivery and shipping operators – like DHL, UPS and the Fedex- are responsible for managing and delivering even higher volumes of goods than that.

Another scenario within warehouses and fulfilment centres that is ripe for improvement is shelf labelling. Often, labels on shelves need to be changed quickly within warehouses. Through peak or any important seasonal period this might happen more frequently as products move around the warehouse or label codes or pricing changes. Traditionally, staff would have printed labels at a stationary printing station and then would walk to each appropriate shelf and change the label – a time consuming process. They’d have to first print the labels, then change them and then dispose of the liners. Again, more waste containers are needed and liners often end up on the floor accidently, causing a slip hazard.

Redesigning efficiency and productivity around mobile linerless printing

This is where mobile, linerless printing offers a better solution. Arming staff with mobile devices and mobile linerless printers enables them to travel around warehouses and fulfilment centres freely. They have autonomy to take on more, their roles can be enhanced and they can become more productive – for instance, using this technology has the potential to enable teams to pick, pack and ship more goods more effectively over peak periods. Which is crucial when its often a struggle to recruit and retain extra staff through and beyond this period.

Traditionally, over 10 years ago, mobile printing was perceived as expensive too, but this perception is now long outdated, and times have changed. The tables have turned. Mobile, linerless printing offers cost and efficiency benefits that supersede many stationary printing solutions and processes. This is because the reels of printing paper used contain more paper to print on; and they don’t need to make space for an extra liner that backs onto the label. The paper being used is often more eco-friendly because it has no liner and because it comes from sustainable resources.

Often less paper is used when printing too. Organisations only need to print as much label as they need, to convey the key information that is necessary to have on the label, at the time of printing. This approach replaces the idea of using a traditional, standard sized set of labels, which often sees the printing space on labels not being used optimally. For instance, an oversized label might be used incorrectly to share only a little bit of information and the traditional liners would need to be disposed of properly too – in this case using the precise amount of paper to print on, via a mobile linerless printer, would be less wasteful, more cost effective and more impactful. Especially since the print quality is better and more robust too.

Further, workflows can be redesigned accordingly, and since more can be printed from a roll, there is less waste to throw away when the roll is complete – also, fewer liners can be found on the ground in the warehouse or fulfilment centre causing health and safety problems.

Improving communication with customers during last mile delivery

It’s not only the warehouse and fulfilment centre that stands to gain from mobile linerless printing. The last mile does too. Often, during the final phase of delivery, when parcels are delivered at consumers’ homes they either accept their goods because they are “in”, or they don’t. When someone is not around to receive, sign-for and accept their parcel, often the delivery company leaves a note. Postal and delivery companies regularly do this.

When leaving a note, the delivery person often writes a message on a card to say when they stopped off to deliver the parcel, and it explains to the consumer how they can collect their delivery given they were not around to accept it. This communication process with customers can fail and cause a bad customer experience if the handwriting and information shared on the delivery note is not legible. Often, information presented can be inaccurate too.

To combat this, linerless mobile printers are increasingly being used to improve the customer communication process. A linerless label can be printed and attached to the delivery note, which is then posted through the consumer’s door. A standard set up could be designed to convey all the necessary accurate information to the customer about how they can collect their new parcel. This process can function alongside other customer proof of delivery processes and support them too. Further, since liners are not used with mobile printers, there is no litter and waste, presenting an additional environmental benefit.

Gone are the days when mobile printing was considered expensive and ineffective. We’ve all seen the power of mobile to transform many field service operations – warehouse, logistics, retail and e-commerce teams are not excluded from these wins. Mobile, linerless label printers, when used alongside mobile devices in warehouses, fulfilment centres, and during last-mile deliveries, have the potential to transform operational processes.

It makes you wonder why any retail, ecommerce or warehouse team doesn’t consider exploring its benefits – especially when many organisations are considering how they can improve their costs and operations to save money for themselves and for their customers.