Brady Corporation offers a new, more cost-efficient solution to quickly detect unstable Li-ion batteries in storage. Able to automatically measure 0,5°C temperature differences per second, the solution provides the accuracy and speed needed to isolate unstable batteries before they become a safety risk.

Fast and accurate

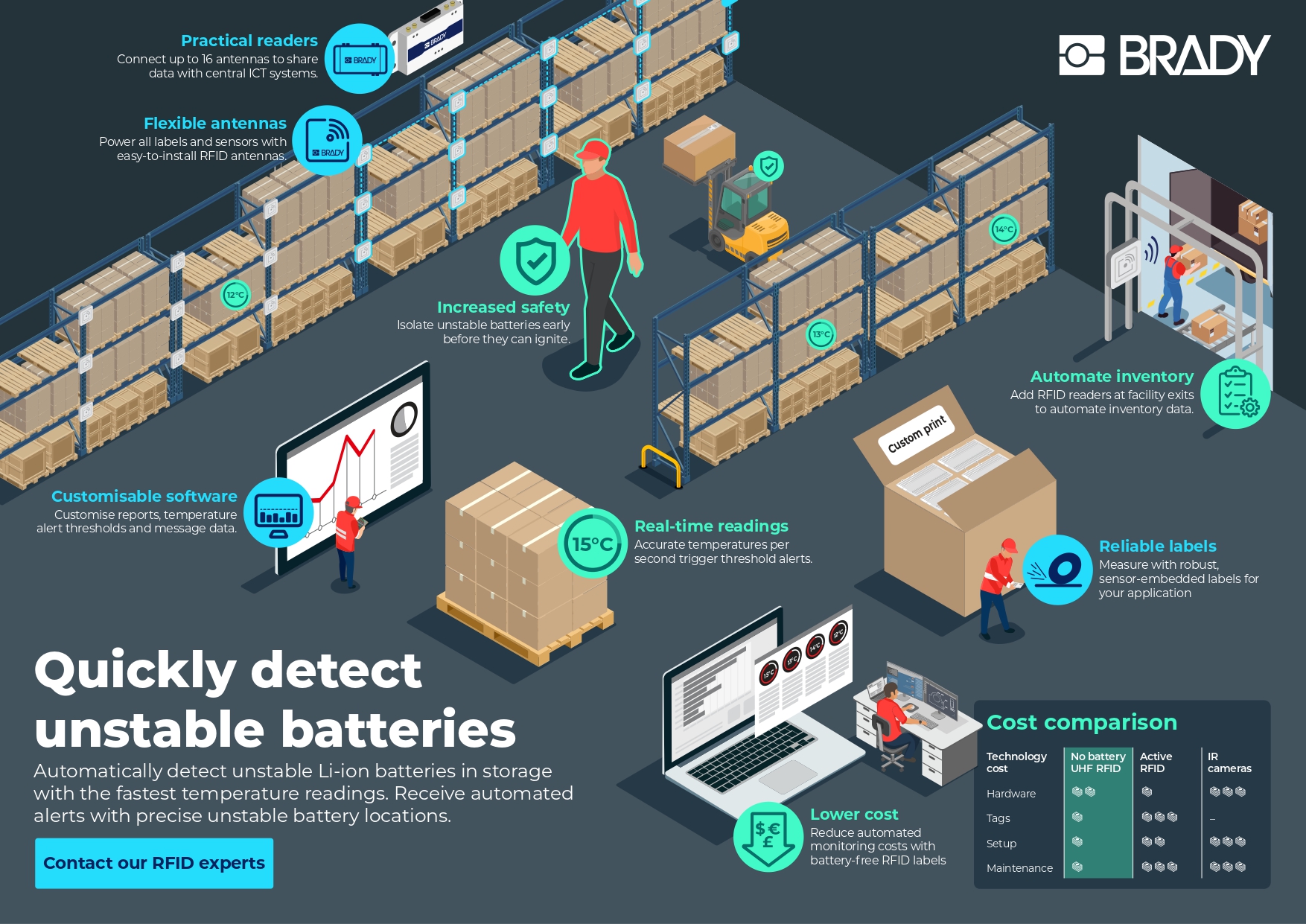

Brady´s new battery temperature monitoring solution involves 3 components: self-adhesive battery-free UHF RFID labels with embedded temperature sensors, RFID readers with up to 16 antennas, and a customisable RFID software platform.

The self-adhesive UHF RFID-embedded labels can be applied inside battery cell boxes for fast temperature change detection. Alternatively, every battery cell can be labelled with Brady´s on-metal, printable UHF RFID labels to enable more elaborate advantages in Li-ion battery supply chains. Every second, the RFID antennas and readers automatically power all labels and sensors in range to collect temperature readings with 0,5°C accuracy. Every temperature reading, and matching battery storage location, is collected by the RFID software platform. When customisable temperature thresholds are reached, the software platform triggers 3rd party devices via standard API.

With almost continuous, automated and accurate temperature monitoring, warehouse stakeholders can receive early warnings via sms, email or even racking warning lights. They can be guided in time to specific warehouse locations for unstable Li-ion battery isolation. Alternatively, Brady´s software platform API can also trigger an autonomous vehicle to automatically remove an unstable battery.

Cost-effective

Battery-free UHF RFID labels with embedded sensors are a more cost-effective battery temperature monitoring solution than powered RFID tags or IR cameras. UHF RFID labels and their temperature sensors receive power wirelessly from RFID antennas and readers in range. They are available at significantly lower costs – up to 5 times less than battery-powered RFID tags – and do not require maintenance.

The number of RFID readers needed to completely cover storage locations in a warehouse heavily depends on warehouse setup, racking height and storage volume per racking compartment. Brady can connect up to 16 antennas to a single RFID reader that provides high accuracy, high speed temperature monitoring for all storage locations in 12 metre wide and 4 metre high racking.

The automated, and almost continuous, nature of the temperature monitoring solution enables Li-ion battery manufacturers and logistics companies to significantly increase safety and reduce risk at advantageous costs.

Automated inventories

By adding an RFID reader gate at designated warehouse exits, Brady´s solution can also enable automated, real-time warehouse inventories. RFID labelled items are read by Brady´s RFID readers the moment their label enters reader range. When they pass through a designated RFID reader gate, these items can easily be subtracted from the inventory by the RFID software platform.

When used in this way, the solution can provide cost-effective battery track & trace inside the warehouse from entry to exit, complete with battery cell box or battery cell temperature fluctuation in between.

similar news