A compact and agile AirRob automated storage system by Libiao Robotics has been installed in the Shanghai warehouse of a specialist lean supply chain management service company.

Founded in 2001, Shanghai Shine-Link International Logistics (SLC) services the specific storage and distribution needs of precision-driven, high-end industrials, from medical devices to advanced electronics, and chemical reagents to mechanical parts. It offers a wide range of services, including supply chain management, international transportation, and various value-added activities.

With a client list comprising international brands such as Coty, Siemens, Pioneer, and Leica, SLC’s services are highly sought-after by companies whose exacting supply chain and fulfilment standards are considered above the normal needs of the average industrial customer. It has recently added a major medical devices, disinfection and hygiene products manufacturer to its list of prestigious customers.

“Smart Logistics” Model

SLC’s stated focus is on providing lean supply chain management services to international multinational companies based on accurate, timely and personalised IoT and digital services. It has developed a “smart logistics” business model with IT at its core, the goals of which include visual management of logistics processes, intelligent traceability management of products, intelligent warehousing and distribution management, and smart supply chain coordination management.

A significant element of this smart philosophy lies within the four walls of its warehouse facilities, where it embraces cutting-edge systems and practices to attract and retain customers requiring a 3PL that can go above and beyond the average SLAs for the sector. Therefore, to best service the medical device company’s particular storage and global distribution requirements, SLC converted a small area of its Shanghai distribution warehouse to a high-density, highly efficient Libiao AirRob storage system.

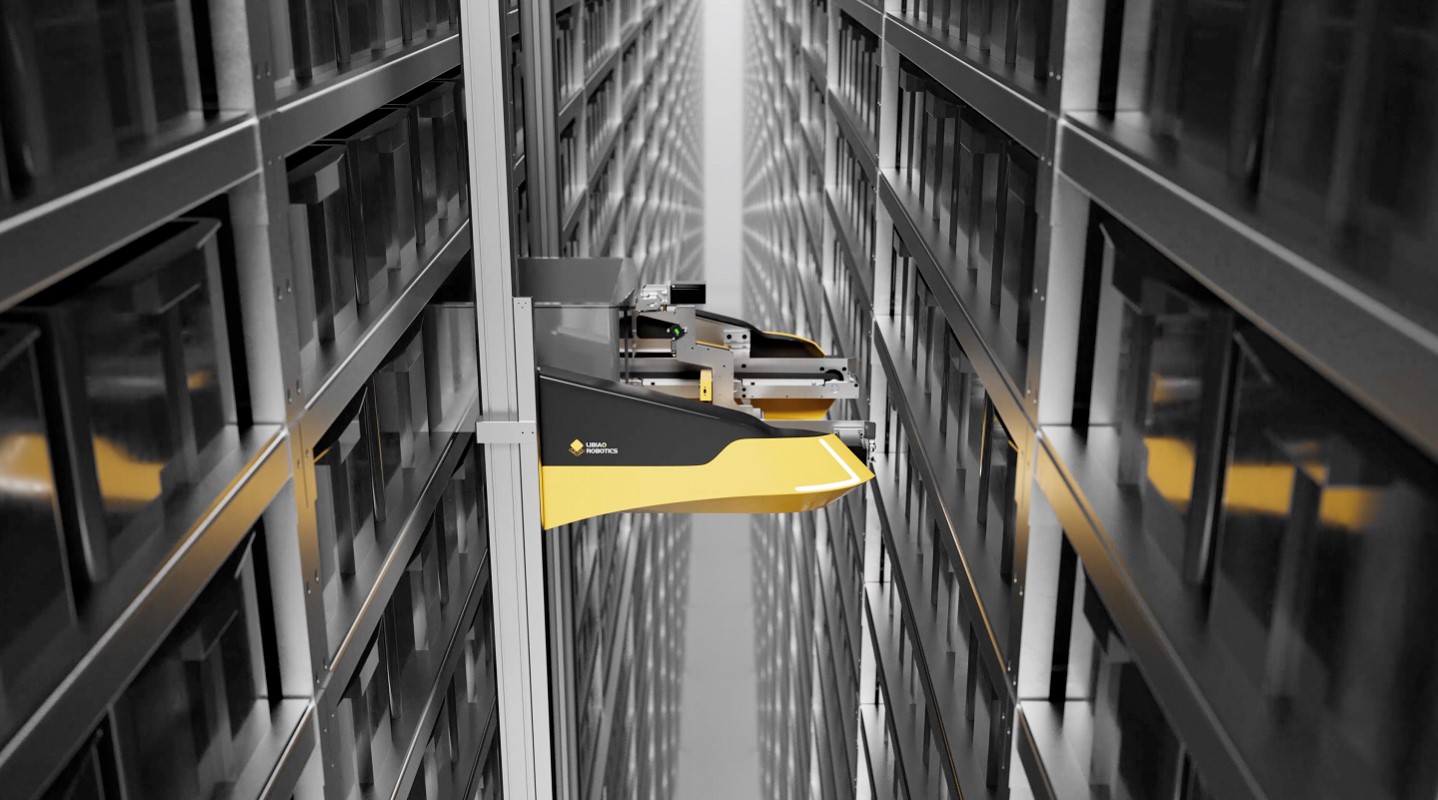

The system Libiao designed for SLC comprises an arrangement of standard warehouse racking serviced by just three hard-working AirRob robots which travel vertically and horizontally on the racking to store and retrieve goods quickly and efficiently. These are serviced by a small fleet of nine ‘floorbots’, which transport the goods to one of seven workstations, where the items are then readied for dispatch.

Reduced Energy Consumption

The multi-award-winning AirRob system offers significant advantages over traditional automated warehouse systems. Its modular design enables rapid installation on existing standard racking within one-to-four weeks without the need to alter existing infrastructure or flooring, making it ideal for retrofits or brownfield developments. AirRob operates in aisle widths as narrow as 0.85 meters, enhancing storage density by up to 30%. Each bot consumes just 150 watts per hour – lower than a microwave – reducing energy usage by one-third compared to similar systems. Its scalability allows for quick and easy expansion to meet growing demands. Additionally, AirRob’s efficient operation can triple throughput efficiency, offering a typical return on investment (ROI) within 12–24 months.

Ding Ling, General Manager of IT BU at SLC, commented on the project: “After going out to the market to compare the different systems and solutions that were available, we decided to select AirRob primarily for three main reasons. Firstly, the fact that Libiao Robotics is the inventor of this type of solution; secondly, the solution represents a good ROI for us; and thirdly, we were attracted by the potential energy savings we can make with AirRob.”

“We’re particularly proud to have been chosen as a supplier to such a prestigious and demanding customer,” said Ronan Shen, Libiao Robotics’ VP of Global Sales. “Not only have we provided a system that meets the precise needs of SLC, but we have managed to successfully achieve this in a particularly space-constrained area of a busy warehouse, without disruption to its ongoing operations. Furthermore, the project represents the first AirRob installation in the medical supplies sector, an industry that lends itself well to the characteristics of AirRob, such as high efficiency and accuracy, a high density of storage, low energy usage, and the careful handling of delicate or valuable items.”

This smaller-than-usual AirRob installation at SLC’s Shanghai facility perfectly illustrates that companies can automate some repetitive tasks or part of their operations at a relatively low cost point, yet still make significant gains in efficiency and accuracy.

similar news