Telefónica Tech, Telefónica’s digital business unit, and Dexory, robotics and data intelligence company, have announced their alliance to promote automated warehouse management.

Both companies will combine their technological capabilities to digitally transform the logistics sector with an innovative service that combines Telefónica Tech’s IoT connectivity and its integration capabilities with Dexory’s AI-powered digital twin platform DexoryView.

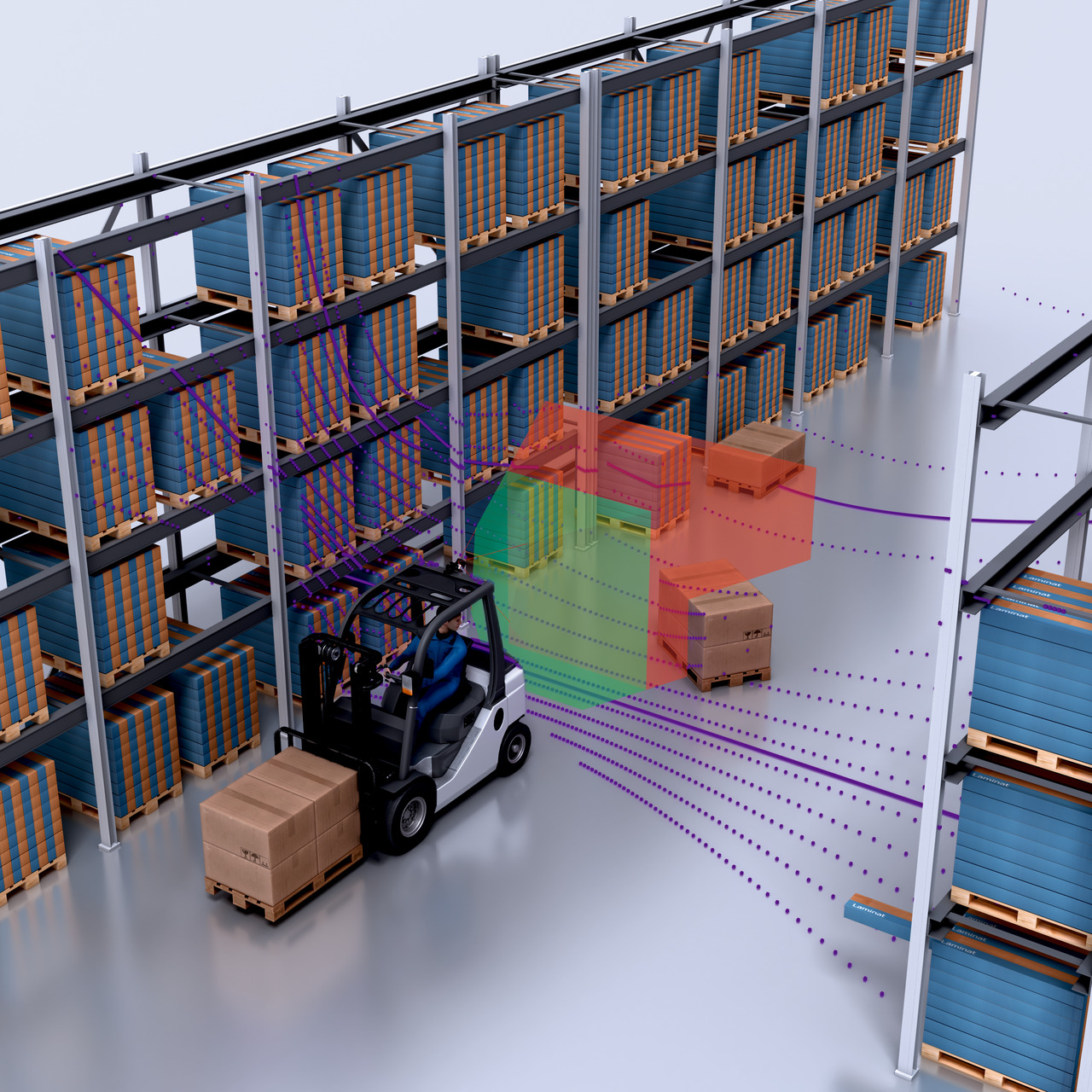

DexoryView uses fully autonomous robots to gather vast amounts of data from warehouses. The robots use advanced optical cameras and LiDAR sensors. These sensors allow Dexory’s robots to measure distances and map spaces and are capable of scanning up-to 10,000 locations per hour.

The data gathered by the robots is analysed in real-time and visualised on the DexoryView platform thanks to Telefónica Tech’s IoT connectivity, providing powerful and accurate information of the inventory accuracy as well as suggestions on optimising the warehouse space. The robots deployed in the warehouse capture data in real time on the status, volume, dimensions and location of the items, using identifiers and barcodes.

Automate Warehouse Inventories

In addition, thanks to its integration capabilities and specialisation in the industrial sector, Telefónica Tech will be in charge of integrating this service with the customers’ Warehouse Management Systems (WMS) to synchronise and comprehensively manage all warehouse operations (location of materials, stock management, task and resource planning, goods in and out, demand planning, etc.).

Alfredo Serret, Global Director IoT at Telefónica Tech, explains: “The alliance with Dexory allows us to strengthen our portfolio of digital services for the industrial sector, which plays a key role in the country’s competitiveness. This service, which combines Dexory’s robotic technology and AI with our IoT capabilities, will enable logistics, distribution and manufacturing companies to simplify the warehouse inventory process by providing them with real-time visibility and accurate data”.

Oana Jinga, Chief Commercial and Product Officer and Co-Founder at Dexory, says: “As in all areas of business, data is key to driving businesses forward. With DexoryView, warehouse operators and managers are able to tap into rich data that will help them strategically guide their businesses forward and unlock new opportunities for them. Partnering with Telefonica Tech will allow Dexory to scale our solutions quickly in the Spanish market and unlock the power of real-time data in warehouses across the region.”

Total control and optimisation of operations

The launch of this service will revolutionize the daily activity of the logistics sector, which will move from having outdated inventory reports to automating the process to have total control of what happens in warehouses and be able to identify inefficiencies and optimize operations. Connected autonomous robots will reduce inventory errors and provide companies with more accurate data on which to base better business decisions. They will also speed up the search for empty locations so that space can be managed more efficiently and will also shorten the time taken to investigate and resolve problems such as the search for lost objects or the detection of erroneous product references.

The warehouse inventory automation service will help the sector to accurately forecast demand, stock and capacity, and will guarantee greater safety by delegating to robots many of the higher-risk tasks that employees have previously performed.

similar news