As Linde MH reinvents the role of the forklift to best service a smart, automated world, Peter MacLeod spoke to two of its senior managers to scratch further below the surface.

At LogiMAT 2025, Linde Material Handling’s shift from forklift manufacturer to strategic intralogistics partner was clear. I sat down with two of its senior leaders, Ulrike Just (Executive Vice President Sales & Service, EMEA) and Torsten Rochelmeyer (Senior Director Strategy & Solution Portfolio), to explore how Linde is helping customers navigate today’s operational challenges – and to have an educated guess at what the warehouse of the future might look like.

Changing Landscape

When I visited Linde’s Aschaffenburg facility last autumn, the company had just unveiled its new three- and four-wheel electric forklift trucks up to 2.0 tonnes. While these trucks remain essential to warehouse operations, their role is evolving. At LogiMAT, forklifts were present but were not necessarily the focal point. That’s no accident, as Just explains: “Our customers aren’t just looking for equipment – they want a “sparring partner”. Someone who helps them optimise logistics processes, understands digitalisation, energy, safety, and can guide them toward automation.”

Rochelmeyer agrees: “The forklift is just one piece of the puzzle. Customers need help optimising entire systems under increasing cost pressure. That includes safety, data, and energy management.”

Linde’s shift from product supplier to holistic intralogistics advisor is deliberate. The company is leveraging its vast sales and service footprint to deliver scalable, integrated solutions across borders. “We’ve seen huge growth through our international key accounts,” says Just. “We’re unique in being able to offer customers a single point of contact for managing a global fleet. Our main competitor, Toyota, has the footprint, but we provide the network depth and advisory capabilities smaller players can’t match.”

One surprising takeaway is that many large customers don’t even know how many forklifts they operate. “We help them get control of that,” Just says. “It’s about fleet transparency and performance optimisation.”

Automation and Digitalisation

Warehousing is Linde’s fastest-growing vertical, particularly in automation. “We see major growth potential in automation, complex energy and safety solutions, and digitalisation,” says Just.

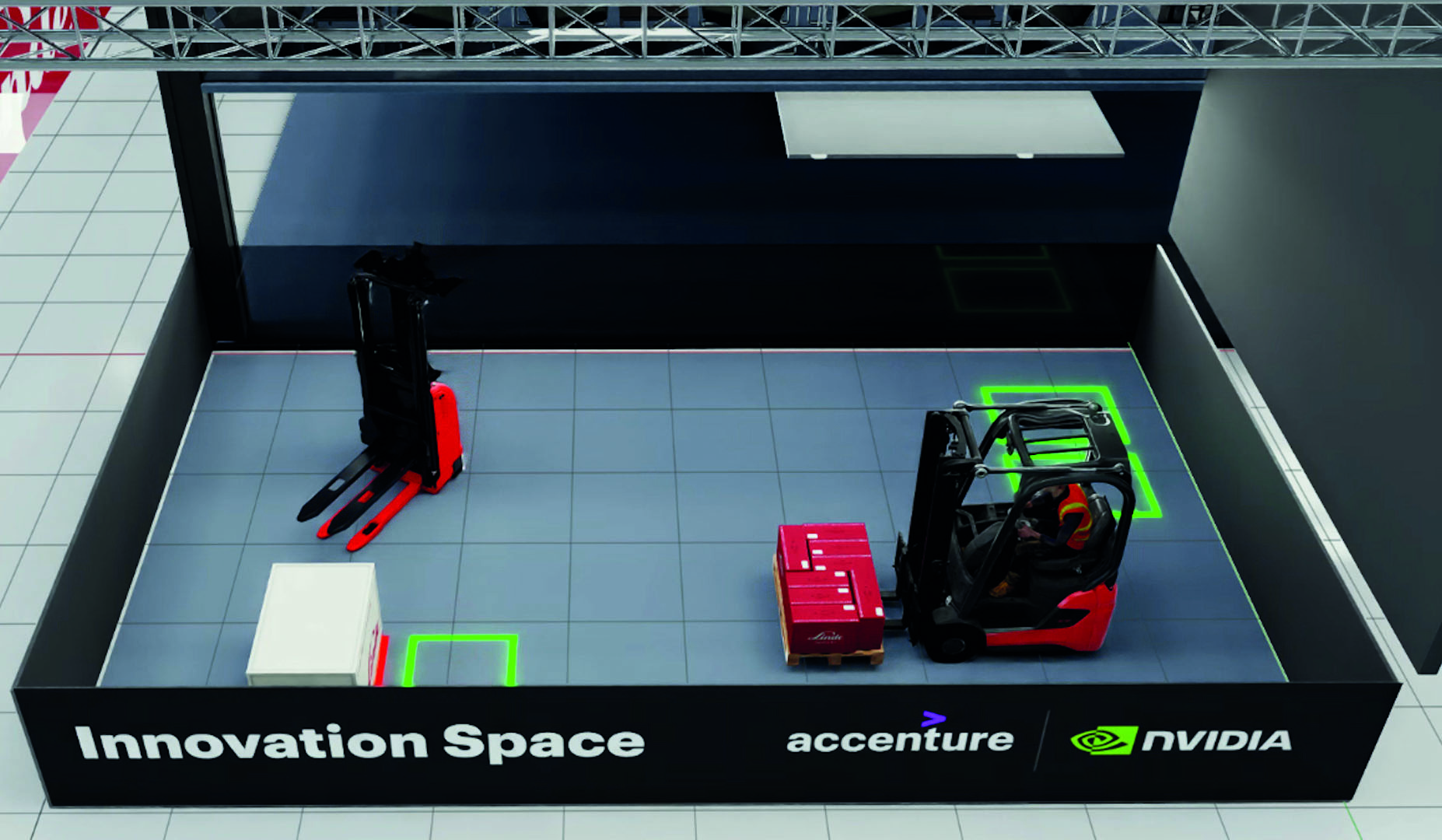

With partners Nvidia and Accenture, Linde is taking AI integration to a new level. “We’re developing physical AI for AGVs so they can react in real time. For instance, AGVs will soon be able to retrieve pallets even if they’re not perfectly placed, which will be a massive efficiency gain,” Just explains.

The second focus is a digital twin of the warehouse, created through sensors that allow for simulation and optimisation of layouts and flows before any physical changes are made. Rochelmeyer highlighted how critical this is for brownfield sites: “Not every customer is ready to invest €30 million in a new warehouse. But many can deploy five AGVs to improve one process. With Nvidia’s Omniverse, they can simulate changes in real time and test outcomes in 3D.”

Sustainability in Action

Linde’s sustainability efforts are twofold: helping customers reduce emissions, while decarbonising its own operations. Its fleet management software, myLinde, works with its connect:charger to monitor energy usage, optimise charging, and reduce carbon output. “Customers can track how much CO₂ they’re saving and report on sustainability improvements to their own stakeholders,” Rochelmeyer tells me.

Within its own facilities, Linde has committed to carbon neutrality by 2050, with a 40% reduction target by 2030. This commitment was recently recognised with an EcoVadis sustainability award.

“We’ve joined the Science Based Target Initiative (SBTI) and have tailored decarbonisation strategies for each plant,” Just says. “That includes switching to green energy, even though it costs more, and building hydrogen infrastructure.”

Linde even powers its internal logistics with hydrogen trucks. “We have hydrogen forklifts moving masts from fabrication to assembly inside our own facility,” added Rochelmeyer.

Hydrogen: Not Yet Mainstream

Hydrogen fuel cells remain an intriguing – but not yet commercially widespread – alternative to battery electric. Linde is ready for it, though: all new forklifts are fuel-cell compatible. “Today, hydrogen demand is mostly driven by pilot projects with OEMs like BMW and Daimler,” says Rochelmeyer. “The business case isn’t quite there for broader adoption due to high infrastructure costs. But when the time comes, we’ll be ready.”

Government support and regional policy will play a key role in speeding up adoption. “Some regions are already more advanced. It’s about timing; too early and it’s costly, too late and you miss the boat,” he adds.

Forklift of the Future

What will a forklift truck look like in 2035? That depends on who you ask, but both leaders agree on one thing: the operator’s role is changing.

“There are two paths,” says Rochelmeyer. “In one, the driver becomes more like a pilot – monitoring rather than operating. Or they may be remotely controlling the vehicle from an office.”

But traditional forklifts won’t disappear. “We’re not like automotive – our sector evolves more slowly, and regional differences are big. Forklifts will still exist, just smarter, safer, and more efficient.”

Just adds with a smile: “Maybe a humanoid robot will replace the driver. You never know.”

Turning Data into Operational Gold

At the core of Linde’s digital push is its new customer portal, myLinde. “It’s more than fleet management, it’s a central cloud platform where customers can track safety, energy, and usage data,” explains Rochelmeyer.

This transparency opens up new optimisation paths: smarter routing, predictive maintenance, energy cost reduction, even fewer trucks. “It’s not about steel and iron anymore. It’s about data.”

Linde Material Handling may still be synonymous with forklifts, but it’s rapidly becoming known for its digital and automation expertise. Whether customers are trying to reduce their energy bills, optimise brownfield processes, or simulate a new warehouse in the metaverse, Linde is positioning itself not just as a supplier, but as a strategic global logistics partner for a fast-changing world.

similar news