Geek+ has been awarded the contract by UK-based warehouse automation integrator Logistex, to deploy 165 Shelf-to-Person robots at Yusen Logistics’ 1.2 million square foot distribution centre in Northampton (UK). The project marks a major milestone in warehouse automation for the 3PL industry and it’s designed for B2B and B2C multiuser operations for chilled and ambient activities.

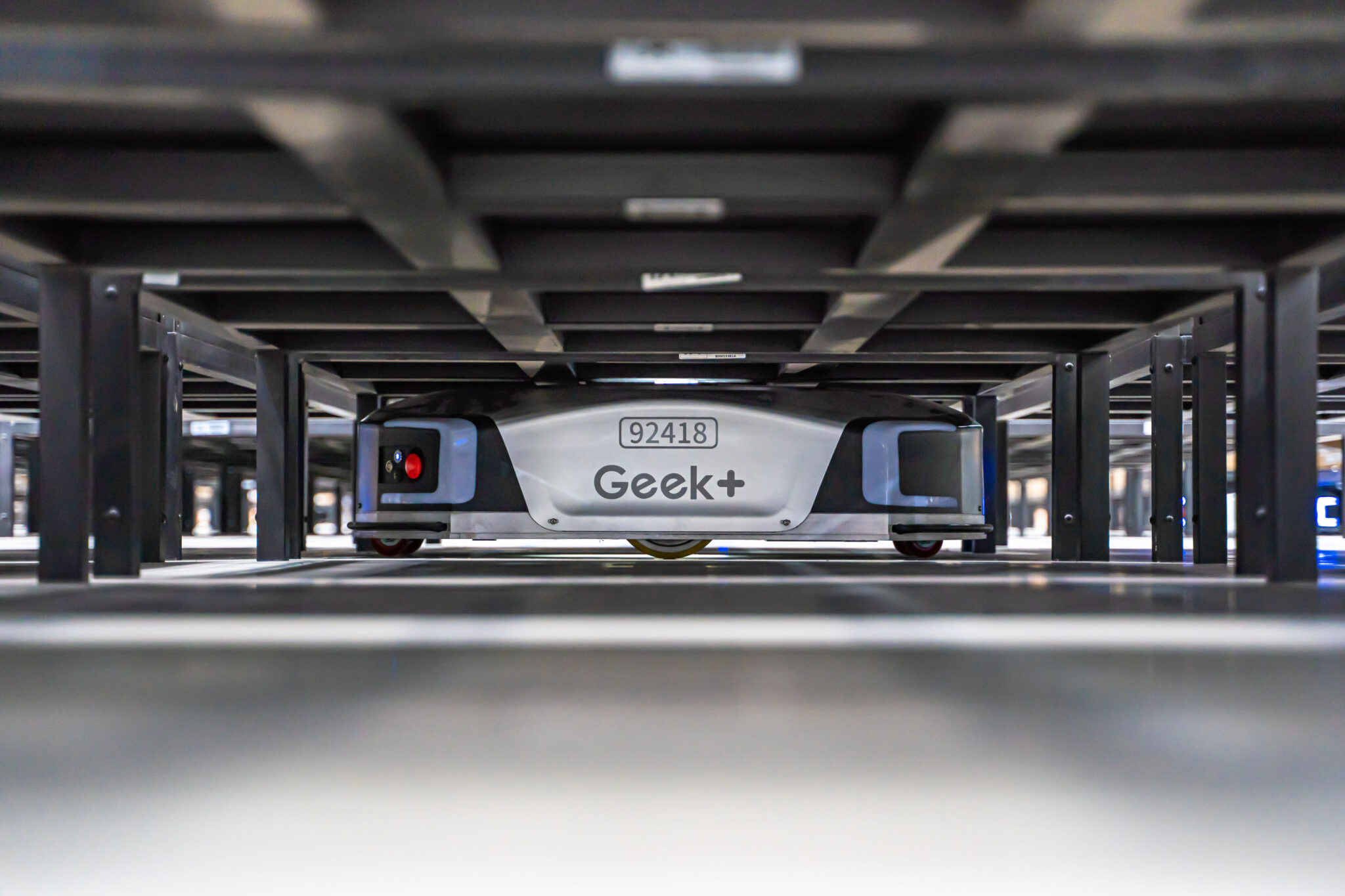

The scalable solution will be implemented in two different phases to ensure business continuity throughout the transformation. Geek+’s P800 V6.0 solution – for pallets and shelves movement – significantly enhances picking efficiency, inventory accuracy, and space utilisation — key advantages for third-party logistics providers facing growing customer demands.

“This project demonstrates the power of flexible automation,” said Simon Houghton, Sales Director UKI at Geek+ . “Our Shelf-to-Person system enables scalable growth without disruption. We’re proud to support Yusen Logistics in their first of this kind automation project in the UK but also in the Europe region”

For Yusen Logistics, the deployment aligns with a broader digitalisation strategy aimed at increasing efficiency and responsiveness across its operations.

“By integrating Geek+’s robots, we will be able to improve accuracy, agility, and throughput,” said Ben Bird, Business Development and Solutions Design Director at Yusen Logistics. “The system will give us the flexibility to scale alongside our customers’ evolving needs while gaining a great customer experience”.

The implementation will be delivered as part of a wider warehouse automation project led by Logistex, ensuring seamless integration with Yusen’s infrastructure and business processes.

“It’s a pleasure working with Yusen and Geek+ on such a forward-thinking project,” said Justin Saw, Business Development Director at Logistex. “Together, we look forward to delivering a future-ready solution with immediate results.”

The project highlights how Goods-to-Person robotics are reshaping the logistics landscape, offering 3PLs fast ROI, reduced labour reliance, and high safety standard. With this deployment, Yusen Logistics is well-positioned to lead in a rapidly changing market.

similar news