With businesses across Europe facing a perfect storm of changing buying behaviours and digital disruption, the time is right for the next wave of business innovation. Hiroyuki Nishiuma, the new managing director at Panasonic System Communications Company Europe (PSCEU), suggests lessons learned from a similarly maturing society such as Japan could help. He predicts the next wave of business innovation will come from ‘Gemba Process Innovation’.

The external pressures shaping business across Europe have never been greater or more varied. As society continues to mature, it brings a host of new challenges and opportunities for industry – forcing them to adapt to thrive. Examples of issues driving this change include those such as changing consumer buying habits, rising environmental and ethical awareness and societal issues such as an ageing population reducing the size of the available labour pool.

In combination, innovation in technology continues to rewrite the possibilities for business. This brings with it both threats and opportunity as disruptors rip-up the traditional rules of commerce, changing the way that manufacturing, supply chains and retail interact. As organisations explore ways to adapt, looking at the experiences of others can be useful. In Japan, Gemba Process Innovation is being used to radically review, redesign and reinvent operations using technology to increase efficiencies and free-up creative potential.

Much-like the business philosophy of Kaizen that came before it, Gemba Process Innovation presents an opportunity to benefit European businesses. But rather than small, incremental continuous improvements that were inspired by Kaizen, Gemba Process Innovation takes a more transformative approach. It combines an in-depth understanding of the organisation and of the latest available technologies to deliver new methods of working.

The gemba is the physical site where value is created. This Japanese word literally translates to “the actual place”. For example, in the supply chain the gemba is where things are made, moved, or sold; the site where value is generated and problems must be confronted: the factory floor, the warehouse, or points-of-sale; these are referred to as the gemba. Each has their own unique processes and goals, but also their own particular challenges. However, the question on the minds of managers of all these operational fronts is the same:

How to innovate and optimise in the face of rapidly changing conditions and customer needs?

In Europe, Gemba Process Innovation is most obviously suited to manufacturing, logistics and retail industries but it has applications across many industries. In manufacturing, Gemba Process Innovation can accelerate automation with the use of technologies such as robotics. In logistics, it can provide the ability to sort, schedule, track and monitor the condition of goods using Deep Learning and sensor technologies connected via the Internet of Things. In the retail sector, it can be used to adopt AI and camera technology to drive personalised digital marketing, as well as automated stock re-ordering to optimise product availability on the shelves.

It all begins with deep business understanding

Of course, technology alone cannot solve these challenges. The first step in successful Gemba Process Innovation is a deep understanding of the existing business process; what works and what doesn’t. This is achieved through consultation, a close observation of the business and industry understanding. However, the workforce itself also has a vital role to play. Employee knowledge about a business’ critical processes is probably one of its greatest assets. Gemba Process Innovation taps into this knowledge.

Often people worry that new technology-driven solutions will automatically mean the loss of jobs, but in my experience, this is not necessarily the case. It is more likely to result in a change of labour requirement. In reality, many of the repetitive and physically intensive job roles are removed and new opportunities are created for the workforce to be engaged in alternative and often more rewarding roles.

Next follows solution design, testing and optimisation

After observation and understanding follows the design of a new solution using technology and processes to deliver new levels of efficiency and productivity. Testing and optimising the solution then becomes the focus to ensure as much value as possible can be delivered from the innovation. Gemba Process Innovation requires a combination of hardware, software engineering and system integration to provide the total solution. In Japan, Panasonic has more than 100 years of business experience to draw upon and has been an innovator in Gemba Process Innovation. It first used the approach to continually evolve its own business and then expanded by offering the service to its customers.

The time is now right to introduce Gemba Process Innovation in Europe. As the European market need grows, Panasonic will continue to strengthen and expand its solutions capabilities here. The process has already begun with the acquisition of European-based company Zetes, a specialist advisor in solutions using innovative technology in the supply chain. Globally, more recently, Panasonic has also invested in a 20% stake in Blue Yonder, a leading end-to-end supply chain software provider; further strengthening its knowledge base and capabilities for the future.

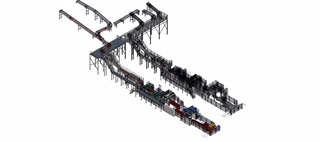

The first business results of Gemba Process Innovation are also already being seen in European businesses. Examples include the deployment of Panasonic’s Visual Sort Assist System (VSA). VSA combines scanning technology, goods detection technology and projection to speed up the process of sorting items on a conveyer belt, through the semi-automation of item checking and routing. The system is designed to be used in sites where the workers pick, relocate, or remove items such as in production & retail warehouses, and sorting and distribution centres.

In logistics

With online sales growing rapidly across Europe and a 69% increase in European parcel deliveries forecast by 2021, Gemba Process Innovation is already benefitting the logistics industry in delivering a quality service under increasing pressure. When one of Europe’s leading parcel delivery companies wanted to offer customers improved real-time tracking of their deliveries, from sorting centers to delivery address they turned to Panasonic. After studying the requirements, Panasonic recommended a combined software and hardware solution for the business. Field trials were conducted using new Panasonic rugged handhelds and Zetes Chronos delivery software to test performance. The electronic proof-of-delivery software helps control and improve collection, delivery and related management processes. It connects drivers, back-office workers and logistics management to provide real-time visibility on goods, vehicles and returnable assets. This ensures perfect delivery, every time, and offers customers visibility on the status of their shipments.

In conclusion, as European businesses position themselves globally to take advantage of the next wave of technological innovation, Panasonic plans to assist them in achieving their goals by becoming a full service provider focusing on these types of industry solutions that transform the gemba – the place where value is created.