Automated picking and handling operations often require the usage of more than one technology in the robotic area. They should be both scalable and flexible. David Priestman got an update from a key player.

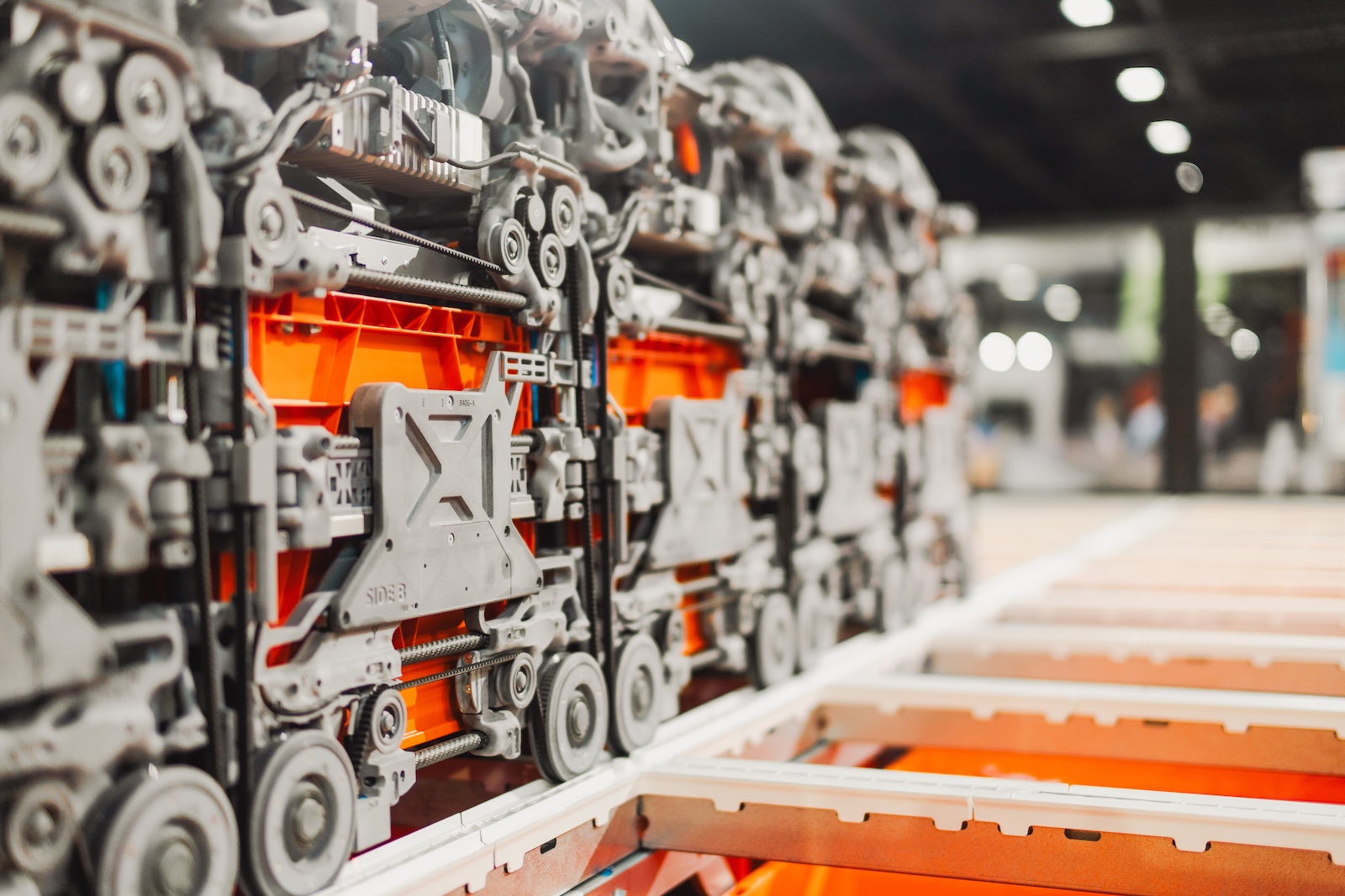

“We’re experts in the hardest area, which is individual item picking,” Ocado Intelligent Automation (OIA) CEO Mark Richardson told me when we caught up with each other at LogiMAT. Having seen the hive OSRS storage and retrieval system close-up myself it is impossible not to be highly impressed by it. With OIA firmly planting its flag in the global materials handling industry, exhibiting at both LogiMAT and ProMat, having both the right mix of products combined with the best route to market is the name of the game now.

Robotic Area

As well as selling directly to non-grocery customers internationally OIA is going to leverage resellers to grow market share. The first deal announced, non-exclusively for the German-speaking market, was with Gebhardt Intralogistics Group. Gebhardt has a wide range of excellent handling and conveying systems, but not an ASRS. “We don’t have presence in Germany, so we’re looking forward to having access to a market that probably wouldn’t (readily) talk to us,” Richardson said. “It gives reassurance to customers that we have a presence. Gebhardt has a stellar reputation in the sector and across Europe, and we trust them to bring deep value and expertise to customers in the region. They have good mid-size capability.”

OIA is in discussion with a small number of other resellers internationally. “It was always our plan to use resellers,” Richardson added. “We’re picky about who.” He anticipates doing projects lead by and sold by Gebhardt (and other resellers) but also vice-versa, with OIA winning the business and taking the lead, utilising local installation, service and maintenance. Expect more announcements.

Call the Porter

The company is extending the ‘Chuck’ range of AMRs to automate further processes. ‘Porter’ is a new AMR pallet-carrier that drives pallets point-to-point, all using the Chuck tech-stack. Porter picks, moves and places pallets directly from the floor with precision, even when they are aligned back-to-back. It recognizes its surroundings to safely handle and transport heavy loads autonomously and can be configured to handle cages, increasing flexibility and expanding fulfilment capabilities.

“Customers might buy just the Porter or Porter plus Chuck,” Richardson informed me. “In existing operations it can be used as an inexpensive pallet mover, collecting open or closed pallets and it can stack pallets immediately adjacent to each other, so there are no gaps. Porter takes us into the case handling and de-palletising robotics area, extending our product range. It will be used for inbound, from the dock door to the OSRS induct stations and loading into the grid – bringing the pallet to the decanter.”

Porter’s advanced vision system enables it to navigate safely and autonomously without requiring infrastructure changes or manual intervention. Moving at speeds of up to 4.5 miles per hour, the AMR dynamically adjusts its speed when detecting people or equipment in the area, ensuring workplace safety. Porter intelligently parallel parks itself in aisles to reduce congestion, keeping operations seamless for both robots and human associates.

Finally, I asked Richardson for an update on OSRS projects being delivered. Canadian pharmaceutical distributor McKesson’s installation will be finished this summer, ready for final testing and go-live. “We have a full pipeline,” Richardson stated, “as well as bidding for many projects.” Watch this space and listen to our Logistics Business Conversations Podcast with OIA on Spotify and other platforms.

similar news

![[Podcast] Future Fulfilment: Smarter, Scalable Warehouses](https://9e1ed6cd27b6b3199380.b-cdn.net/wp-content/uploads/2025/07/square-logo.png)