The pandemic has propelled ecommerce to new heights, making online retailers’ use of oversized, wasteful and excessive packaging unsustainable. By Jo Bradley, Business Development Manager for packaging solutions at Quadient.

It is said that on average every man, woman and child in the UK receives 140 parcels a year. That figure is likely to have risen dramatically over the pandemic, as the UK Office for National Statistics reports internet purchases rising to 31.3% of total retail sales in December 2020.

However, surveys consistently find that up to 40% of consumers believe online deliveries often arrive in boxes way too big for the items they contain, while a ‘Which?’ survey reports 48% of customers agree that “excessive packaging is one of the most annoying things about online shopping”.

Sustainability is a growing consumer concern. The same surveys show that many customers feel more positively about brands that are trying to reduce unnecessary packaging. At least the cardboard is seen to be recyclable – not so the bubble wrap and the polystyrene beads. Particularly baffling to consumers is when voids in the box are filled by even more cardboard boxes!

Excessive packaging is not just an annoyance to consumers. Without adequate dunnage in the voids, goods can be damaged in transit, and boxes become more susceptible to crush damage. Oversized boxes create unbalanced loads, causing back problems for warehouse and delivery staff, even when the overall weight of the package is quite low. Oversize boxes also waste transport space and delivery vehicles invariably ‘max out’ on volume long before they reach weight limits. Shipping empty space simply doesn’t make sense – it’s wasteful both environmentally and financially.

Society also pays. Companies that generate significant amounts of packaging are subject to Packaging Recycling Obligations (PRO), which means they either take their packaging back for recycling, or pay a fee in lieu. This raises £73 million a year in support of recycling efforts, but English local authorities estimate the cost to them of handling cardboard packaging is more like £700 million and rising: the Smithers PIRA consultancy predicts ecommerce packaging use to increase by 14.3% per annum over 2017-2022.

So how do you reduce the waste associated with oversized packages. The technology now exists to create fit-to-size boxes for every consignment while improving throughput at packing stations and dramatically reducing a range of costs.

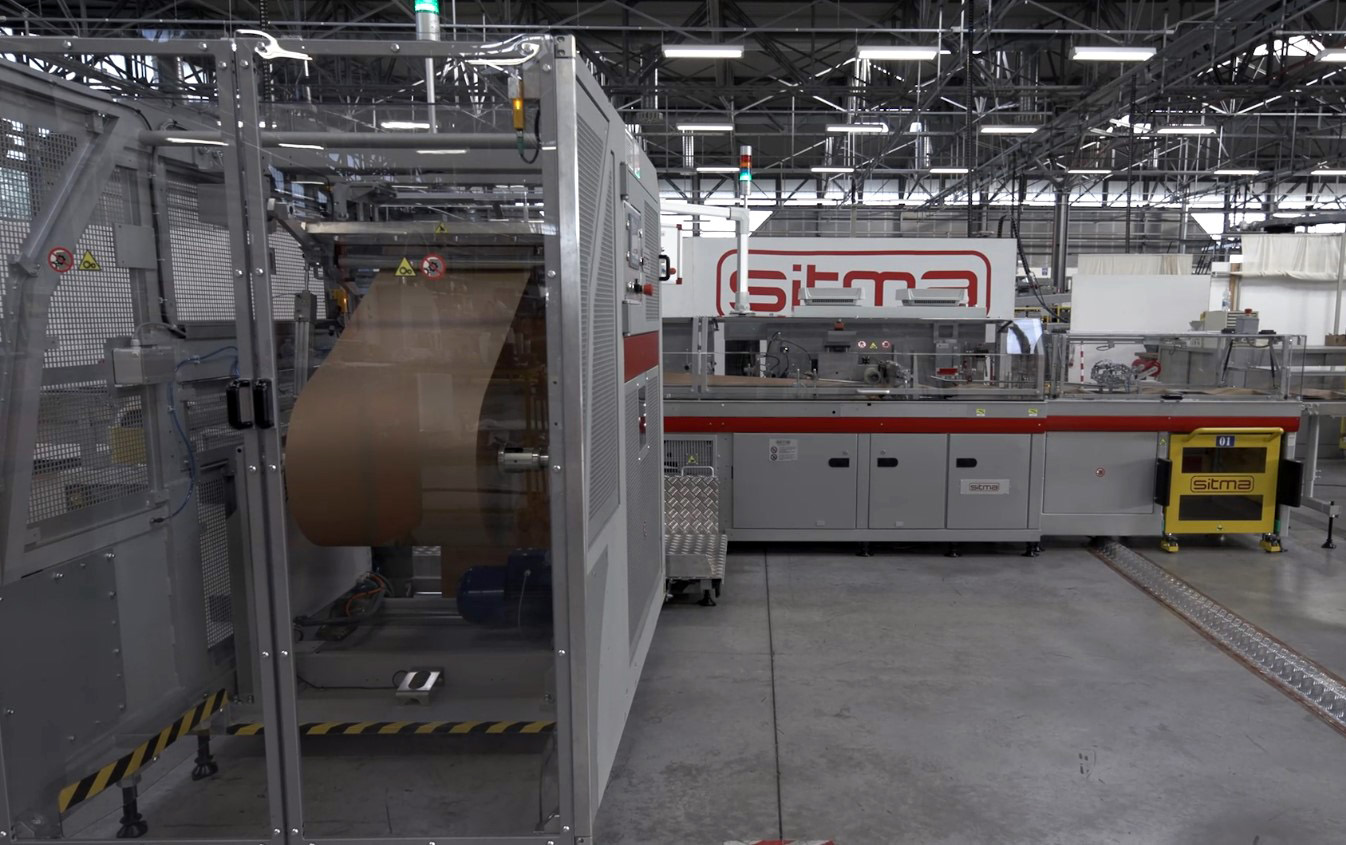

The CVP Impack autopacker from Quadient sizes (using 3D scanning), constructs, tapes, weighs and labels each individual order – whether of individual or multiple items. With a cycle time as short as seven seconds a single operator can do the work of up to ten packing stations – constructing up to 500 packages per hour. For enterprise-level volumes the CVP Everest can create up to 1,100 boxes per hour.

Typically, these machines offer a 20% saving in the use of cardboard and a complete elimination of void filling materials. Reductions in shipped volumes of up to 50% have been achieved. Packing errors are also reduced through check-weighing, invoices/returns labels automatically generated and included, and labelling can be integrated with automated carrier rate-shopping software.

So a packing line can achieve higher and more accurate throughput with fewer staff, major savings on packaging material costs, lower transport volume requirements, a minimised exposure to recycling obligation payments, lower consumer anxiety and a positive message on sustainability.

Fit-to-size packaging technology is transforming ecommerce packing performance. For more information go to www.packagingbyquadient.com