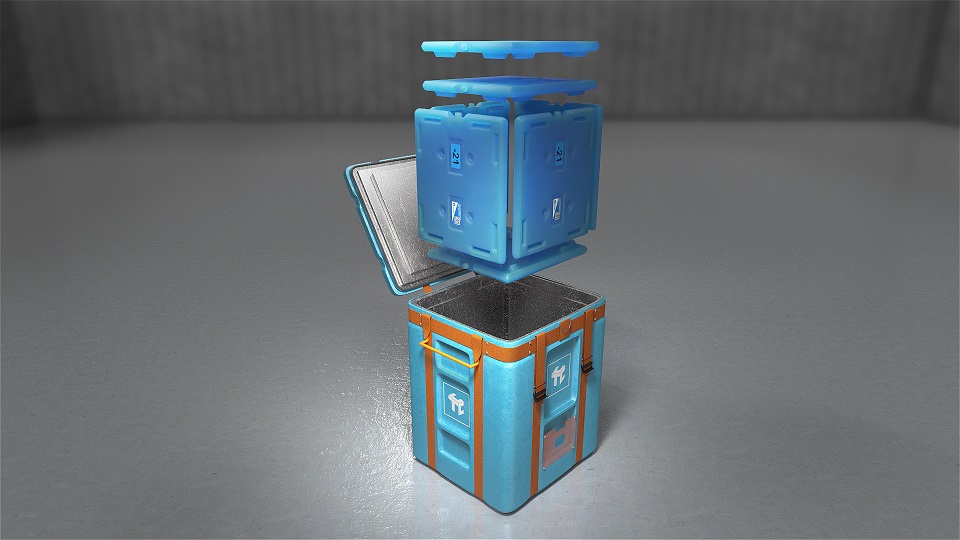

Zebra Technologies Corporation, a leading digital solution provider enabling businesses to intelligently connect data, assets, and people, has launched its new line of environmental sensors. The full solution, including the new ZS300 sensor, ZB200 Bridge and Android Sensor Discovery app, further expands Zebra’s opportunity to transform environmental exposures into customer insights.

Using these sensors, manufacturers, wholesalers, transportation and logistics operators in the food, pharmaceutical and healthcare industries now have cloud-based visibility into a range of environmental factors, including temperature monitoring and moisture detection. This will enable them to know if products have been maintained within appropriate conditions across the supply chain. The sensors help improve profitability by allowing users to take corrective action in real time and maximise their productivity with a more efficient data logger.

“We’re excited to expand our sensor technology to address the need for cost-effective supply chain visibility and data insights,” said Tony Cecchin, Vice President and General Manager, Supplies and Sensors, Zebra Technologies. “The ZS300 electronic sensor extends our robust portfolio, including visual and printable indicators, providing customers the ability to drive smarter business decisions, reduce waste and increase efficiency.”

Zebra understands its customers’ needs for continuous visibility into the handling of environmentally sensitive items, particularly for the food, pharmaceutical and healthcare industries that must move products safely across the supply chain. The new ZS300 electronic sensor addresses the current challenges faced with heightened consumer concerns about medications or food being compromised in transit with a secure cloud platform that makes it easy to integrate temperature logging into a wide variety of applications and systems of record. They are available in multipacks and include minimal biodegradable packaging and a no-cost recycling program to help reduce the impact on the environment.

Only four-in-10 pharmaceutical decision-makers surveyed in Zebra’s Pharmaceutical Supply Chain Vision Study said they completely trust the entities within the pharmaceutical supply chain to keep medications safe and uncompromised throughout the supply chain. And according to the Zebra Food Safety Supply Chain Vision Study, only an average of 37% of industry decision-makers and 20% of consumers place complete trust in the industry to ensure food and beverage safety. Zebra is a market leader in asset tracking, and this new solution extends the power of Zebra’s mobile computers and tablets as data can be collected from these devices to provide immediate visibility to the temperature exposure of shipments.

Ivanti Wavelink, an Independent Software Vendor (ISV) partner, is one of the first to develop a software solution for the ZS300/ZB200 electronic sensors solution using APIs, SDKs and documentation from Zebra to provide temperature insights with location. The Ivanti Velocity Client and Ivanti’s Neurons for IIOT platform support the ZS300 solution to seamlessly enable the integration of environmental sensing into enterprise systems.

“Environmental sensors address critical needs of businesses in the market, and we are excited to collaborate with Zebra to deliver for our mutual customers,” said Brandon Black, Senior Vice President, and General Manager, Ivanti Wavelink. “Today, we are seeing customers place a lot more emphasis on monitoring the conditions of goods where spoilage can result in costly recalls and adversely affect their bottom lines. With Zebra, our combined solution helps customers gain a competitive edge while reducing risk.”