Rugged devices and mobile computers can improve supply chain performance for transport operations, field workers, drivers and delivery teams, according to one manufacturer, Getac.

One of the key lessons learnt by the global supply chain industry over the last few years is the critical importance of having robust supply chain processes in place, particularly because customers today demand short lead times and fast delivery.

Developing resilient supply chains won’t come overnight, but having the right technology in place is fundamental to achieving it. In particular, the use of rugged devices and solutions is seeing significant growth throughout the transport and logistics (T&L) sector as whole. In fact, a recent study by IDC and Getac found that 65% of T&L organisations are now spending at least 10% of their IT budget on rugged devices, with 51% planning to increase their spending over the next 12-18 months.

Overcoming Industry Challenges

Rugged technology can help enhance efficiency and resolve many of the ongoing challenges that the T&L sector faces: whether that’s a need to improve transparency in the supply chain, eliminate inefficiencies in data gathering or meet health and safety, environmental and sustainability regulations.

Unexpected events from severe weather to ‘black swan’ events can impact T&L operations overnight, which is why the sector needs ready access to technology that can provide visibility and deliver valuable insights. Rugged technology does just that, enabling companies to better track key performance indicators, identify inefficiencies, and make data-driven decisions that optimise processes and reduce costs.

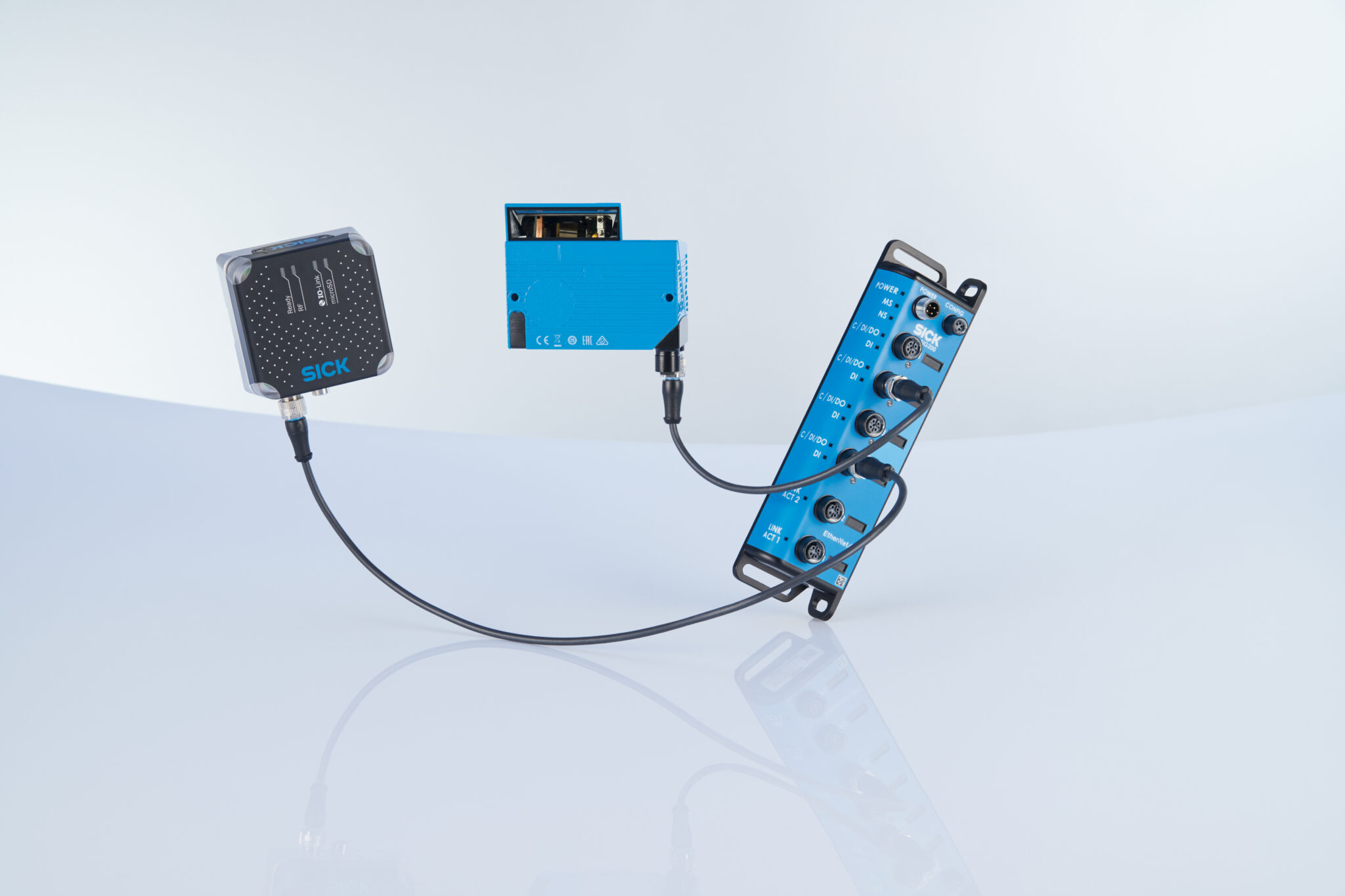

A growing number of T&L companies also now use IoT sensors on assets and goods, which give them real-time information on a range of parameters such as humidity and temperature while in transit. When integrated into supply chain management systems, these insights can help inform decisions on things like delivery schedules, with rugged devices serving as the platforms through which drivers/managers access and receive this information.

At the same time, real-time GPS tracking can help keep workers safe in adverse weather conditions, while dispatchers can use it in combination with real-time traffic data to route drivers via the most eco-friendly routes possible, helping to reduce their carbon footprint.

The operational visibility that rugged technologies offer also helps track energy consumption and optimise productivity. IDC’s study found a growing number of T&L organisations were looking to integrate rugged devices into warehouse management, customer relationship, and supply chain management systems, all in a bid to improve efficiencies in the supply chain and boost worker performance.

The Business Case

The business case for rugged devices extends far beyond durability alone. The combination of powerful specification, extensive connectivity and reliability makes them ideally suited to T&L environments, where a single device can travel hundreds of miles a day and be used in a wide range of locations, temperatures, and weather conditions. Most rugged device fleets can also be scaled up easily, using centrally managed security protocols that make it easier for IT teams to protect sensitive data, regardless of where the device physically is.

While upfront capital investment in a rugged device stack might be a little higher than consumer-oriented equivalents, the total cost of ownership (TCO) shakes out in favour of rugged devices. Digital transformation in all sectors, including in T&L, depends on reliable, always-available, accurate data, which can also help automate supply chain processes. The ability to deliver this data when needed means rugged devices can unlock a range of efficiencies across the entire supply chain.

Whether companies are looking to improve their customer service metrics, boost sustainability initiatives, comply with regulations, cut down on waste in last-mile logistics, or improve worker productivity, rugged devices are essential in helping meet these goals.

Implementing Rugged Devices

Rugged devices might be a must-have for T&L operations but making a wise investment decision means considering the following factors in TCO calculations:

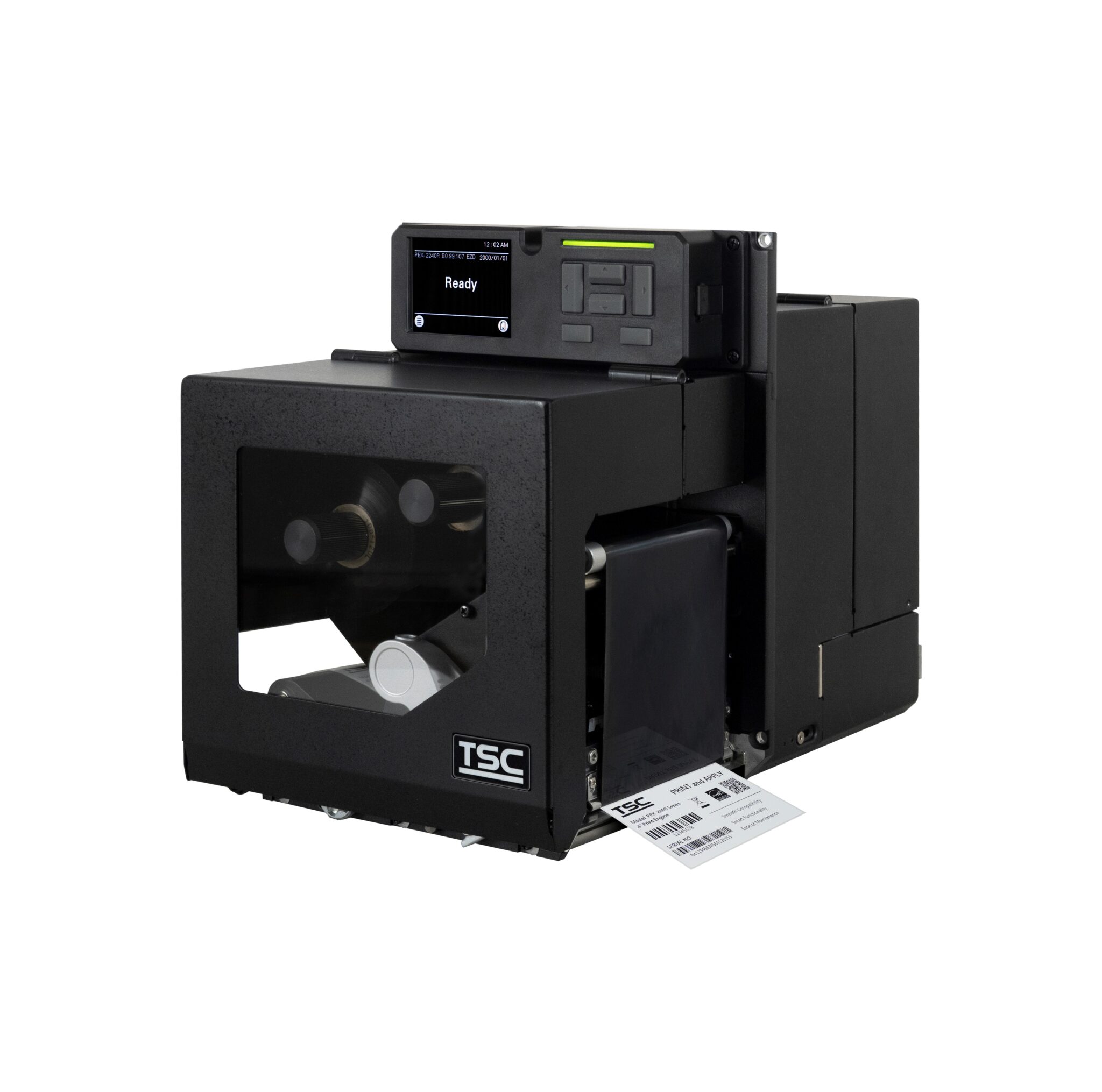

Ease of integration with in-house supply chain software systems: For rugged devices to do their job, which is to facilitate access to data, they need to integrate with software systems for that information. Companies need to ensure that rugged devices will work with existing supply chain and warehouse management systems. Integrating rugged devices with inventory management systems such as ultra-high frequency (UHF) RFID is crucial to optimise inventory processes and improve efficiency.

One of the key concerns that many companies have is that rugged devices expand the company’s data systems to the edge. Trusted rugged device vendors have robust security protocols in place to keep data secure. Likewise, organizations must evaluate the range of operating conditions that their fleet of rugged devices will need to withstand and pick the right devices accordingly, using the device vendor’s industry experience to guide their decision-making.

The best practises for integrating rugged devices into T&L operations extend beyond the ones listed here. Companies should conduct a comprehensive TCO assessment and ensure a ramp-up period to iron out any potential issues that might surface. Most importantly, the C-suite needs to ensure workforce buy-in, so team members see the devices as aids that help them do their job better while improving efficiency.

No one can predict when the next supply chain shock will occur but being able to access data in real time keeps T&L companies agile and able to withstand ups and downs. Now is the time to invest in rugged devices to make T&L operations function smoothly and ready to take on any challenge.

similar news