Locus Robotics, a leader in autonomous mobile robots (AMR) for fulfilment and distribution warehouses, has attracted more than $117m (£97.6m) in Series F funding, led by Goldman Sachs Asset Management and G2 Venture Partners. As part of the financing, Mark Midle, Managing Director, Goldman Sachs, and Zach Barasz, Partner, G2 Venture Partners, will join the Locus Board of Directors, bringing their unique industry perspectives and insights to further guide Locus’s next stage of growth and global expansion.

“Locus has established itself as an innovative, high-quality market leader for flexible automation in the massive warehouse fulfilment and distribution market,” said Midle at the announcement of the funding. “Our investment reflects our view that Locus has the product offering and the operational excellence required to meet and exceed the market challenges posed by today’s dynamic economic environment.”

“This new round of funding marks an important inflection point for Locus Robotics as we look toward our next stage of growth, and we strategically chose to bring in investors with a wealth of experience in both public and private markets to advise us as we continue our journey,” said Rick Faulk, CEO of Locus Robotics. “As the rapid digital transformation of the supply chain continues, warehouses increasingly seek flexible, intelligent robotics automation to improve productivity and grow their operations, despite ongoing labour shortages and exploding order volumes.”

Funding partner “thrilled”

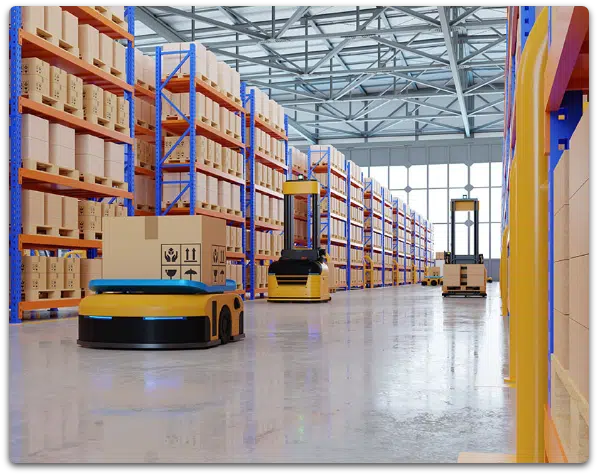

The Locus warehouse execution platform disrupts large-scale warehouse fulfilment and distribution with an industry-leading, intelligent, and dynamically scalable robotics-driven solution. Locus delivers 2-3x productivity by seamlessly coordinating both human labour and AMRs to dramatically improve order fulfilment efficiency and workplace ergonomics, while lowering operational costs.

“Locus is clearly a winner in the flexible warehouse robotics space, and the consistency with which the Locus team has executed is extraordinary,” said Barasz. “We are thrilled to be investors in Locus Robotics, and to partner with the leading warehouse execution company in making global supply chains faster, more cost-effective, and more resilient and sustainable.”

With more than 230 sites under contract around the world – some having as many as 500 LocusBots per site – the Locus solution efficiently and seamlessly orchestrates the operation and management of multiple robot form factors, and provides forward-looking, real-time business intelligence, critical for optimising productivity, proactively managing labour, and managing costs.

“By 2026, 75% of large enterprises in product-centric businesses will have adopted some form of intralogistics robots in their warehouse operations,” said Dwight Klappich, Analyst, Gartner. “The lower price of entry and faster time to value of robotics opens the market to more companies that can justify automation … as companies adopt robotics, most organisations will expand and scale their use of robotics within the enterprise, leading to fleet growth.”

“As order volumes continue to increase and labour shortages persist worldwide, robotics automation is now a must-have for warehouse operators,” said Ash Sharma, Managing Director, Interact Analysis. “Locus is uniquely positioned as a leader in digital transformation in this enormous global market as warehouse operators increasingly focus on scalability, fast ROI, and ease of deployment.”

Flexible and scaleable solutions

Locus partners with the world’s leading warehouse operators to create a powerful synergy that speeds deployment and delivers powerful, actionable business intelligence to optimise warehouse productivity, cost management, and labour management.

“Our five-year partnership with Locus has enabled DHL to deliver more resilient, flexible, and scalable supply chain solutions to our customers to support faster delivery, improve operational efficiency, and reduce employee workloads,” said Sally Miller, CIO of DHL Supply Chain North America. “In that time, Locus’s ability to integrate groundbreaking technologies into our operations seamlessly and in a targeted way has been a tremendous success for our customers’ supply chains.”

In September 2022, Locus reached a major milestone with its industry-first 1 billionth pick. It took Locus 1,542 days to pick its first 100 million units and just 40 days for the last 100 million picks. Locus robots now average more than three million picks per day around the world.

Locus counts more than 90 customers worldwide, including CEVA Logistics, DHL, Material Bank, Boots UK, GEODIS, Ryder, Verst Logistics, Radial, and others, who are consistently doubling and tripling their fulfilment productivity, with near-100% accuracy, using the Locus solution.

Also participating in the Series F round were Stack Capital Group, Next47, Stafford Capital Partners, HESTA, Newton Investment Management North America, Gray’s Creek Capital, Silicon Valley Bank, Hercules Capital, Inc., BOND, and Scale Venture Partners.