Configuring machine vision inspections in 3D is now possible in a “snapshot”, thanks to the combination of SICK’s powerful and compact Visionary-T Mini AP camera with the new easy-to-use SICK Nova 3D Presence Inspection sensorApp.

The SICK Visionary-T Mini AP uses best-in-class time-of-flight snapshot technology to set new standards of data accuracy for detailed environmental perception at rapid production speeds. It captures both the 3D depth and 2D intensity values of every pixel at an exceptional (512 × 424 px) resolution in a single shot of light, at up to 30 3D frames per second.

Common 3D Vision Tasks

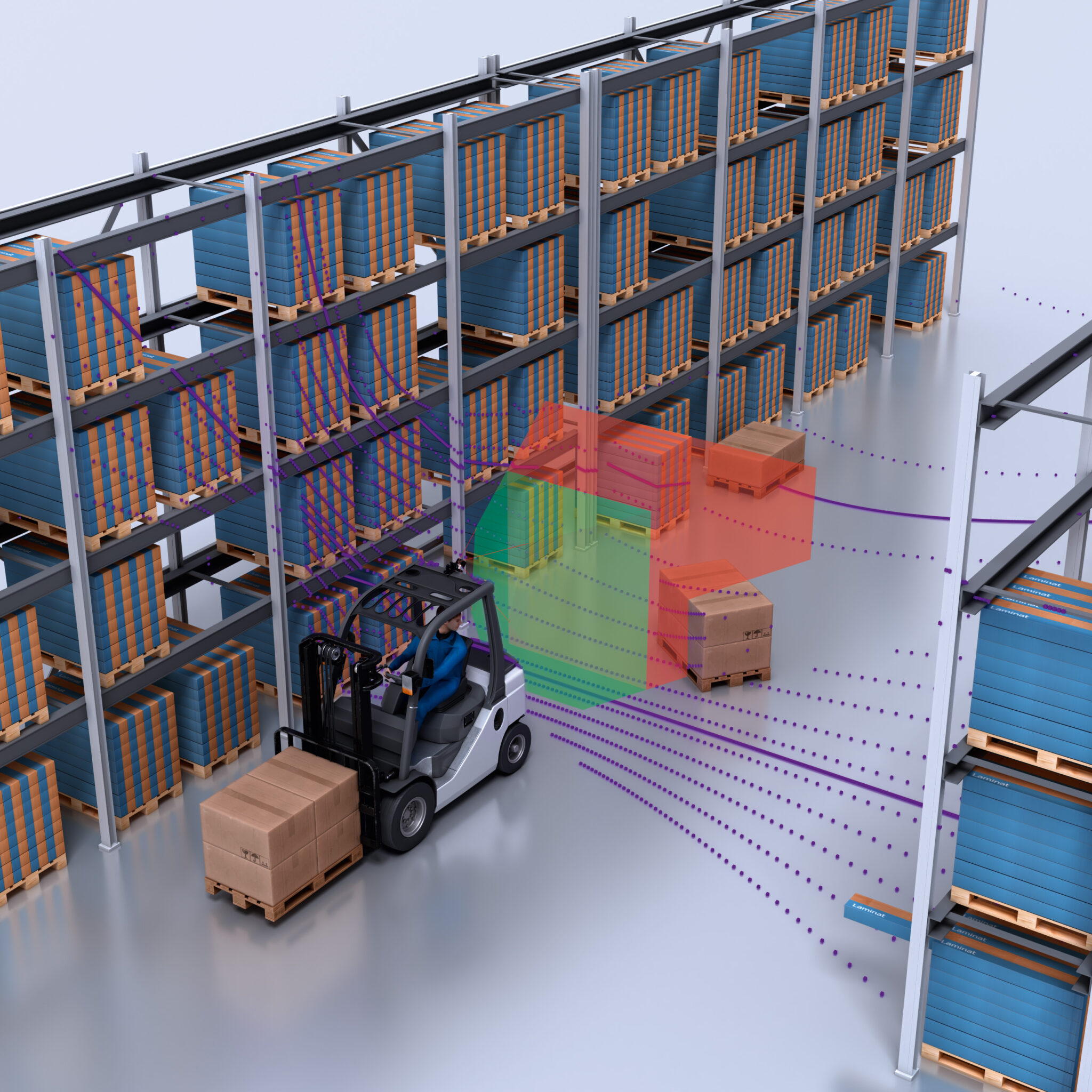

Common 3D inspection tasks in warehousing and logistics such as completeness, fill level monitoring, or robot palletising, can be set up rapidly and cost-effectively to run onboard the Visionary-T Mini AP camera using the SICK Nova 3D Presence Inspection sensorApp. Users simply select the 3D machine vision tools they need via an easy graphic user interface and the Visionary-T Mini AP camera is soon delivering reliable inspection results via I/O to the machine controller or over TCP/IP.

No Programming Skills

“Thanks to SICK’s Nova foundation software, you don’t need programming skills to run a ready-made sensorApp directly onboard our smart devices,” explains Nathaniel Hofmann, SICK’s Market Product Manager for Machine Vision and Measurement. “With the SICK Nova Presence Inspection toolset, you can easily configure a 3D machine vision solution that exactly matches your application.

“Just select the tools you need from the App to run directly on board the Visionary-T Mini AP. The graphical user interface is simple to use, from where you also can also access other industry-standard vision tools, or install one of the ready-made, application-specific solutions should you need them.”

As a programmable device, the SICK Visionary-T Mini AP is easy to configure and commission. A multicam mode is available to process image data from more than one Visionary-T Mini. With rapid 3D data transmission, the Visionary-T Mini is suitable for integration into most industrial applications.

3D Vision Toolset

With a toolset of commonly used 3D vision tools, the SICK Nova Presence Inspection App easily masters tasks like emptiness checks in bins, totes and crates, presence detection of objects in 3D scenes, as well as simple measurements and quality tolerance checks. “3D quality checks for completeness often need several, more advanced, machine vision software tools and programming skillset to identify the quality inspection issue, but with SICK Nova Presence Inspection, they are easy to configure,” Hofmann adds. “The camera outputs results, such as confirming all parts are present and at the right locations, or verifying a set of measurements.”

Using the SICK Nova Presence Inspection on Visionary T Mini, the position, height and volume of any package can be determined, for example for a robot to pick it and place it in a container or pallet. The Visionary-T mini-camera’s 3D snapshot technology can also be used for continuous 3D Fill Level monitoring for example to determine if totes are empty, filled, full or overfull, or it can measure the presence of parts in a bin, for example.

With a low-weight and no moving parts, the Visionary-T Mini’s IP65/67 housing measures just 80 mm x 70 mm x 77 mm, ideal for installation in compact robotics and automation solutions. It performs reliably despite the shocks and vibrations of applications such as robot palletising and depalletising. The automatic High Dynamic Range of the Visionary-T Mini ensures even widely-varying contrasts and lighting conditions across a scene are captured in each frame without complex set up, or expert knowledge of time-of-flight settings. The high-density 512 x 424 px resolution is complemented by a 70° x 60° field of view.

The SICK Visionary-T Mini CX provides an alternative option for customers wishing to use the power of the Visionary-T Mini’s snapshot technology to stream 3D data for their own software applications.