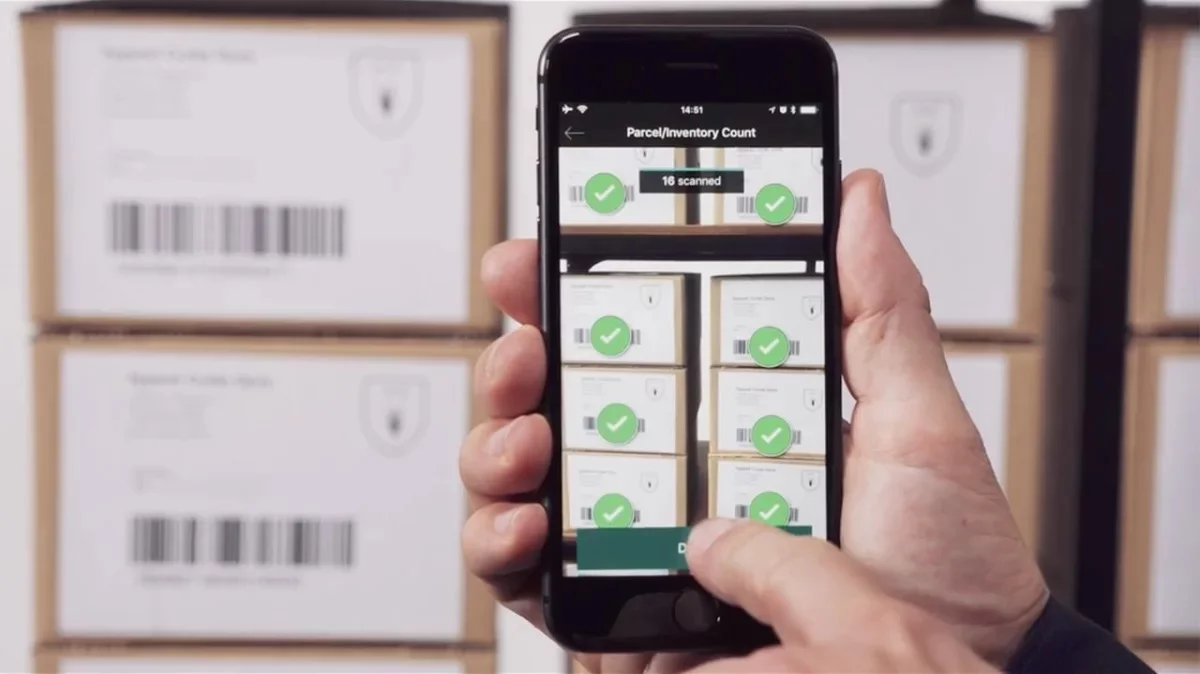

WEROCK Technologies GmbH, an innovative provider of industrial IT solutions, introduces the Rockscan W100, a wearable barcode scanner that sets new standards for efficient and flexible scanning. The Rockscan W100 enables effortless and fast hands-free scanning, offers the best scanning performance in its class and is rugged and durable.

Working in industry, logistics and retail, numerous barcodes need to be scanned every day. The Rockscan W100 was developed to speed up and optimize this process. As a workflow accelerator, it enables effortless and fast scanning while keeping the user’s hands free. With state-of-the-art technology and multiple carrying options, the Rockscan W100 offers a flexible solution to the challenges of the traditional barcode scanning process.

The Rockscan W100 is not only powerful, but also rugged and durable. It is ideal for harsh environments where conventional scanners fail or are not reliable enough. It can withstand drops from up to 1.5 meters onto concrete and more than 2000 drops from 1.2 meters. It therefore exceeds the drop resistance according to MIL-STD-810G and is waterproof and dustproof according to IP65.

The wearable barcode scanner is equipped with a number of innovative features that make it one of the most powerful and versatile barcode scanners on the market. These include

– Easier and faster scanning: The Rockscan W100 features advanced scanning technology that enables fast and easy barcode scanning with a read range of up to 14 meters.

– Long battery life: The Rockscan W100 is equipped with a powerful battery that enables up to 5,000 scans per charge.

– Rugged construction: The Rockscan W100 is designed for use in harsh environments and can withstand drops from up to 1.5 meters onto concrete.

– Flexible applications: The Rockscan W100 can be used as a pocket scanner, ring scanner or back of hand scanner.

– Intuitive feedback: The Rockscan W100 provides acoustic, haptic and visual feedback to avoid errors.

“We are proud to launch the Rockscan W100, an innovative barcode scanner that meets and exceeds our customers’ requirements. It is the result of our many years of experience and expertise in the field of industrial IT solutions. It is the performance booster for the workflows of our customers who work in a world where time savings and precision are of crucial importance,” says Markus Nicoleit, Managing Director of WEROCK Technologies GmbH.

Typical areas of application for the Rockscan W100 include

– Retail: Incoming goods, inventory tracking and point-of-sale transactions.

– Transportation & logistics: parcel tracking and warehouse management.

– Warehousing & Distribution: Warehouse management, receiving, picking, sorting.

– Manufacturing: Inventory management, parts and finished product tracking, assembly.