Drive technology manufacturer and supplier SEW-Eurodrive promises improved energy efficiency and increased throughput with its modular and scalable product range, reports Paul Hamblin. For such a dominant company, 90 years old, with 57 worldwide sites, 17 production plants and no fewer than 22,000 employees, SEW-Eurodrive is not perhaps the most famous name in European and global logistics. That’s probably because it has carved out an enviable position in one of the industry sectors which is talked about the least, but which matters more than most.

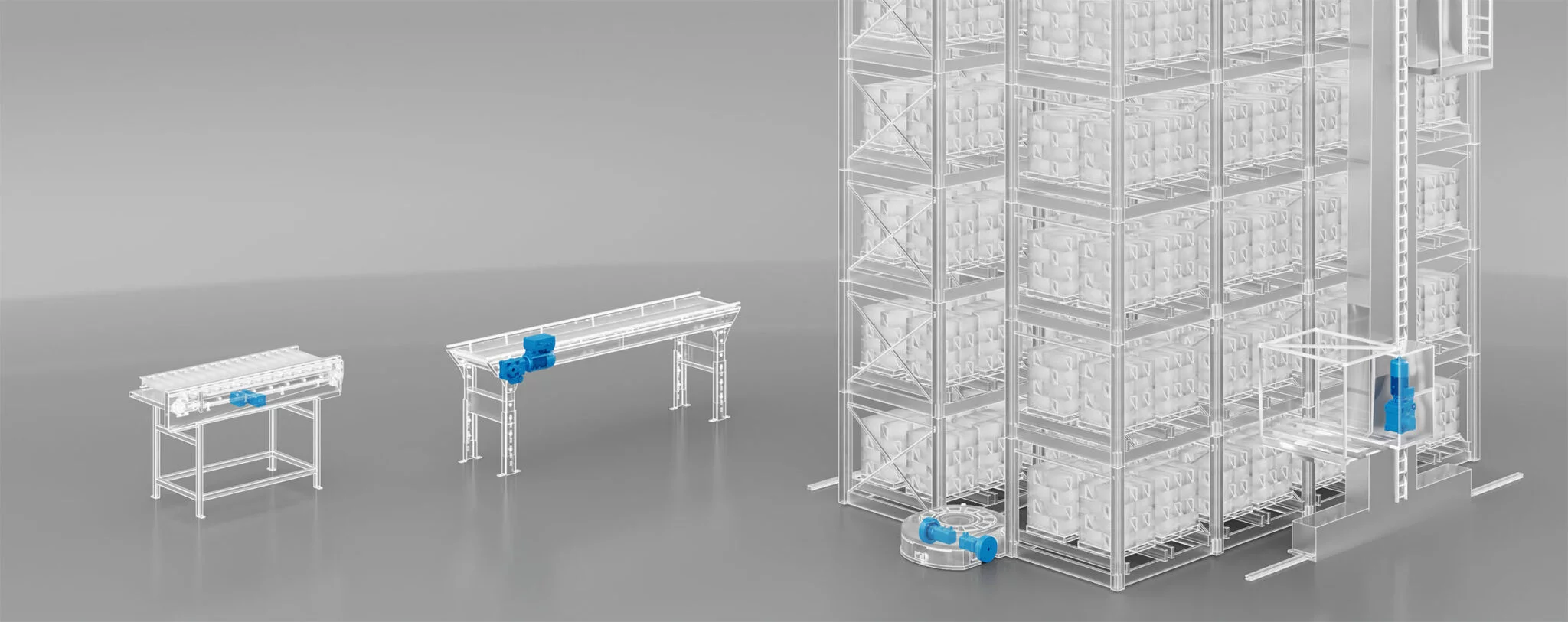

Based in Bruchsal, Germany, SEW-Eurodrive is a specialist in drive technology. Its products enable movement in the handling, storing, sorting, transporting and distribution of goods in logistics. That means powering the conveyors, stacker cranes, palletisers and sorters, and a great deal more besides.

At LogiMAT in March, the company highlighted its focus on three key needs which its customers have identified: energy efficiency, throughput enhancement, and greater flexibility. SEW-Eurodrive’s Wolfgang Currle, Head of Sales Southwest Germany and responsible for SEW-Eurodrive’s presence at LogiMAT, told me that the company’s holistic concept is designed to coordinate perfectly with each customer’s application, with each of these three needs an integral part of the solution. It should be added that short installation times and minimal maintenance work are increasingly demanded by customers, so these requirements are a given.

Energy and Throughput Efficiency

Energy efficiency is achieved via a holistic concept consisting of drive technology, energy management, safety, software and control technology. With SEW-Eurodrive’s products, customers can expect high throughput, smart material flow, maximum energy efficiency, fast startup, and simple operation and diagnostics, all backed up by scalable and robust project planning.

Catching the eye in the company’s product portfolio is the MOVI-C modular automation system, which it describes as “the perfect one-stop shop for every automation task”. All parts and services are made and provided directly by SEW-Eurodrive including all hardware and software, from planning and startup to operation and servicing. Crucially, the MOVI-C is modular and scalable according to customer need. Currle says the benefits of this complete package are “full comfort, a future-proofed system and the reassuring confidence that comes from knowing you have a direct contact you can always rely on.”

Reduced Complexity

Simplicity in the pursuit of user-friendliness is the core product promise of the MOVI-C modular automation system, he says. “The aim is to make complex, high-performance automation and drive technology simple enough for you to install it effortlessly, operate it intuitively and monitor it easily,” he continues.

Deploying the hardware reduces complexity, installation space and costs – all the customer has to do is connect SEW-Eurodrive’s components, which link via plug-and-play, including to each other. With configurable devices and end-to-end control technology, the manufacturer reduces the number of device variants without losing any functions. They include everything from safety to robotics, maintaining the full range of movements.

As for the software, the MOVIKIT modules are easily started up via graphical configuration and diagnostics. The range of standardised software modules includes everything from simple drive functions, such as speed control and positioning, to challenging motion sequences as well as motion control functions such as robotics. Nonetheless, if the application requires, MOVIKIT software modules can also be freely programmed.

The MOVIKIT software modules are perfectly coordinated with MOVI-C control technology. Using MOVISUITE engineering software, the appropriate MOVIKIT software module is allocated directly to an axis or the controller and configured via graphical wizards and editors. As a result, the user has access to all relevant parameters from motor startup to software settings in a single parameterisation interface.

MOVIKIT is integrated into the IEC user program at the touch of a button using automatic IEC code generation. It is both quick and easy to complete. Every software module offers both a conventional variable interface and an object-oriented interface for implementing cutting-edge software architectures.

The control technology is based on a common platform for control cabinet and decentralised controllers with the same functionalities and identical interface diversity. The controller is used to execute high-end data-driven applications that require integrated functional safety and high-level, application-specific networking. Motion, automation and cyber physical control are all available with the system.

The AC motor, servomotor and linear motion drives are fully modular, with an enormous range of combinations to suit specific requirements. “Just connect and you’re good to go, thanks to an electronic nameplate and digital single-cable technology,” explains Wolfgang Currle.

similar news