A state-of-the-art shuttle system, automated processes for incoming goods, 130,000 storage bins, and new picking workstations: Erwin Müller has significantly expanded its warehouse capacity at the Buttenwiesen / Germany site. FORTNA was commissioned with the concept design and implementation of the new future-oriented distribution operations, where they were a driving force and key partner throughout the project up to the go-live in December 2023.

Founded in 1951 as a textile wholesaler, Erwin Müller Versandhaus GmbH continues to grow. The company has gradually developed into a multi-channel specialist for home and household textiles and has proven it has the knack for understanding consumer needs when it opened an online shop in 1997.

“Since opening our online shop 27 years ago, we have always focused on being one step ahead of market requirements, and our current project is no exception: greater capacity, more flexible fulfillment and customer service that sets new standards,” explains Tobias Eder, Managing Director at Erwin Müller. “After so many years of being able to count on FORTNA’s technical expertise and implementation skills, we once again entrusted project manager Andreas Beermann and his team with the concept design and upgrade to our distribution operations.”

The data collected was used to design the upgrade, which consists of a new building with a main incoming goods centre and a shuttle and dispatch system connected to the existing building via a bridge. FORTNA devised a solution that took place in stages during ongoing operations. The new building will operate as a central warehouse for all items that can be ordered via the catalogue and online shops. The official opening ceremony for the new building took place in May 2021, while steel construction and other installation work for the automated logistics systems were completed in 2023. The shuttle warehouse, with 16 aisles, now provides an additional 11,000 m² of usable space. “We have combined new systems and inventory fulfillment in a multi-site strategy designed to consolidate orders and ensure high-performance processing,” explains Andreas Beermann, Sr. Manager Solution Design at FORTNA. “In the new incoming goods center, automation will significantly increase profitability and efficiency.”

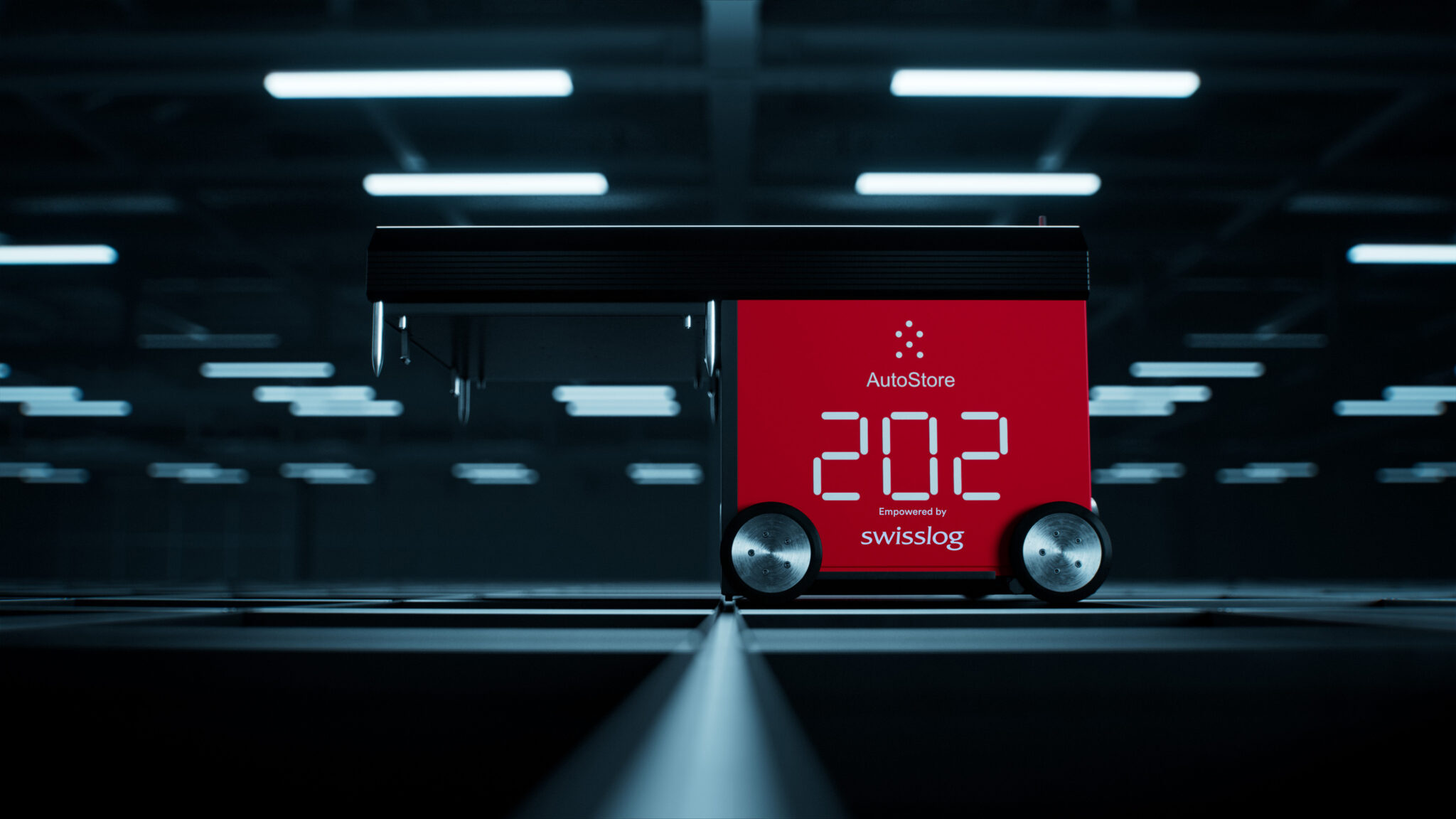

Incoming articles are registered in the new building extension, transferred to containers as required, and scanned into the system using new barcode scanners. One hundred fifty-two shuttle (152) vehicles are used to transport and distribute the items automatically to the appropriate storage locations. The shuttle vehicles can be in either the shuttle warehouse for storage or directly to the eight (8) new ergonomic pick and pack workstations. Once there, they are manually picked to order and packed in up to 180 shipping cartons per hour for international dispatch. This close interaction between manual and automated processes increases productivity, saves time and reduces the error rate.

As Tobias Eder states, “With the support of FORTNA, we have put in place a future-proof solution at Erwin Müller’s central operations in Buttenwiesen that organizes the flow of goods to the best possible extent, is able to react flexibly to changing customer and industry requirements, and also offers sufficient capacity for future growth.”

read more