Itoh Denki, a leading international specialist in motorised drive roller (MDR) based material handling technologies, is set for a busy first quarter of 2024, with major innovations to be displayed at two major international trade shows in March.

The company will be exhibiting at both SITL (stand J086) – short for ‘Salon International du Transport et de la Logistique’ – and LogiMAT, the leading international trade show for intralogistics solutions and process management (stand 1K25). Both shows will welcome visitors from 19th to 21st March in Paris and Stuttgart respectively.

At each event, Itoh Denki will be showcasing major innovations which will bring new opportunities for efficiency and flexibility across a broad range of applications.

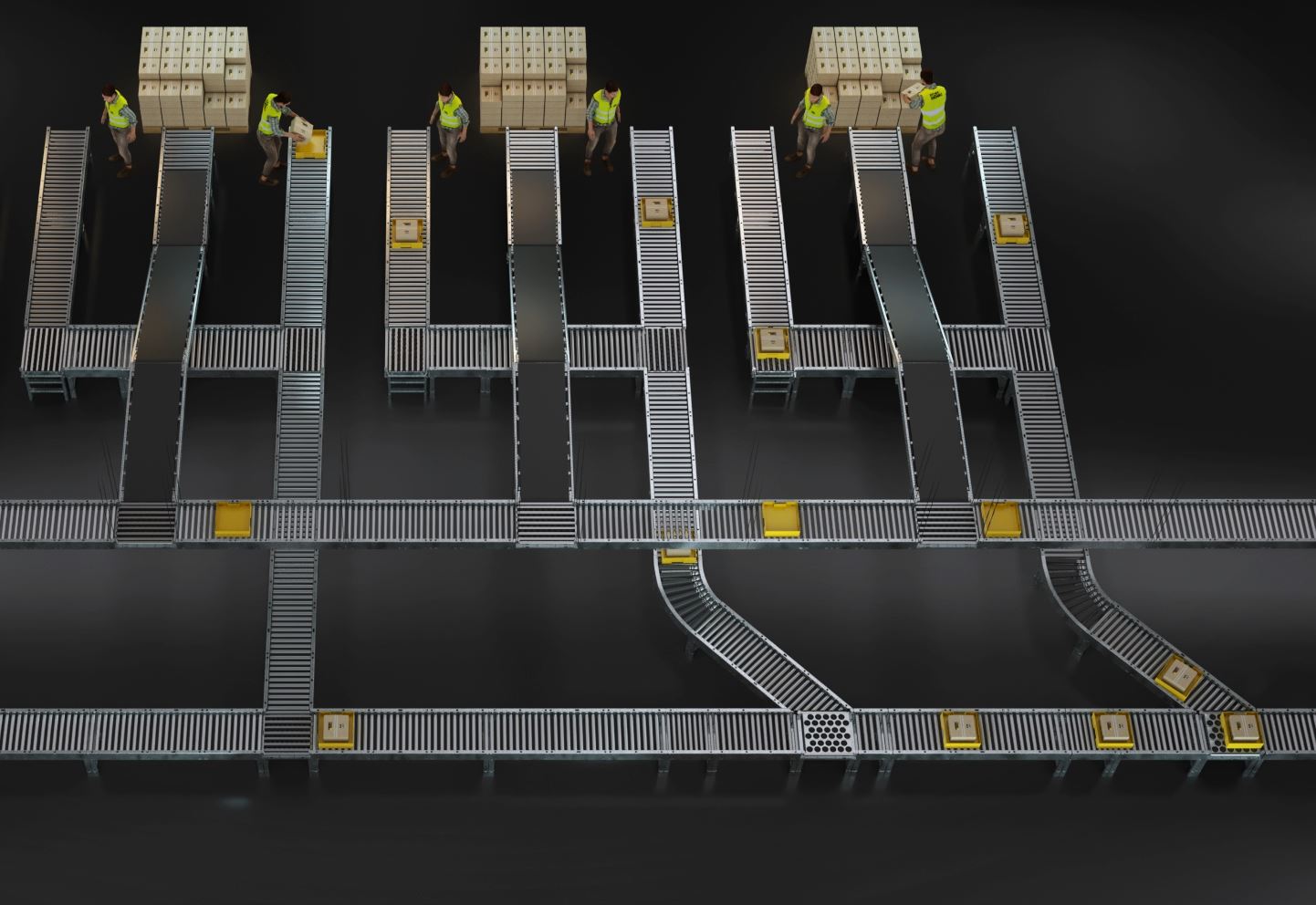

Among the new products on display will be M-RAT, a highly innovative new diverter and sorter module, developed in response to burgeoning demands from customers globally for systems which can cope with heavier products, especially in manufacturing or on assembly lines. Drawing on a similar acclaimed 24V DC powered design which form the heart of the company’s F-RAT compact 90° diverter and sorter module for the precise transferring of smaller loads, M-RAT will be able to handle individual loads of up to 250kg. This will provide greater flexibility for specifiers and designers needing to move heavier loads who have previously had to rely on heavily motorised or pneumatically powered systems which bring very specific challenges around commissioning, maintenance and safety.

Also on show will be a prototype of FNR, a new MDR-powered conveyor module which transfers loads via an innovative patented bed comprising plastic wheels. Offering a ready alternative to traditional belt conveyors and belt on roller conveyors when handling small items, FNR is a highly cost-efficient solution boasting supreme safety, near-silent operation and very low maintenance. A versatile solution for many applications, it notably offers a practical and cost-efficient solution for singulation of items for order preparation. The prototype on display will demonstrate how FNR can be used in a singulation application, conveying and separating small individual packets of sweets.

Tatsuya Akashi, President of Itoh Denki Europe, explained: “We have exhibited regularly at both SITL and LogiMAT in recent years, and every year, both events have proved highly valuable in reinforcing existing contacts and forging new partnerships. We’ll have knowledgeable colleagues from our expert European team on hand throughout both events to discuss customers’ application requirements and demonstrate our technical capabilities. We look forward to welcoming decision-makers and specifiers from across Europe and further afield to our stands.”