Clustag by Rielec, a global leader in innovative RFID solutions, has announced that it has been appointed by global warehouse robotics provider Exotec as a strategic partner to deploy item-level RFID solutions in selected Skypod® System projects. The technology will be deployed in some specific projects in the Netherlands for a globally known fashion brand

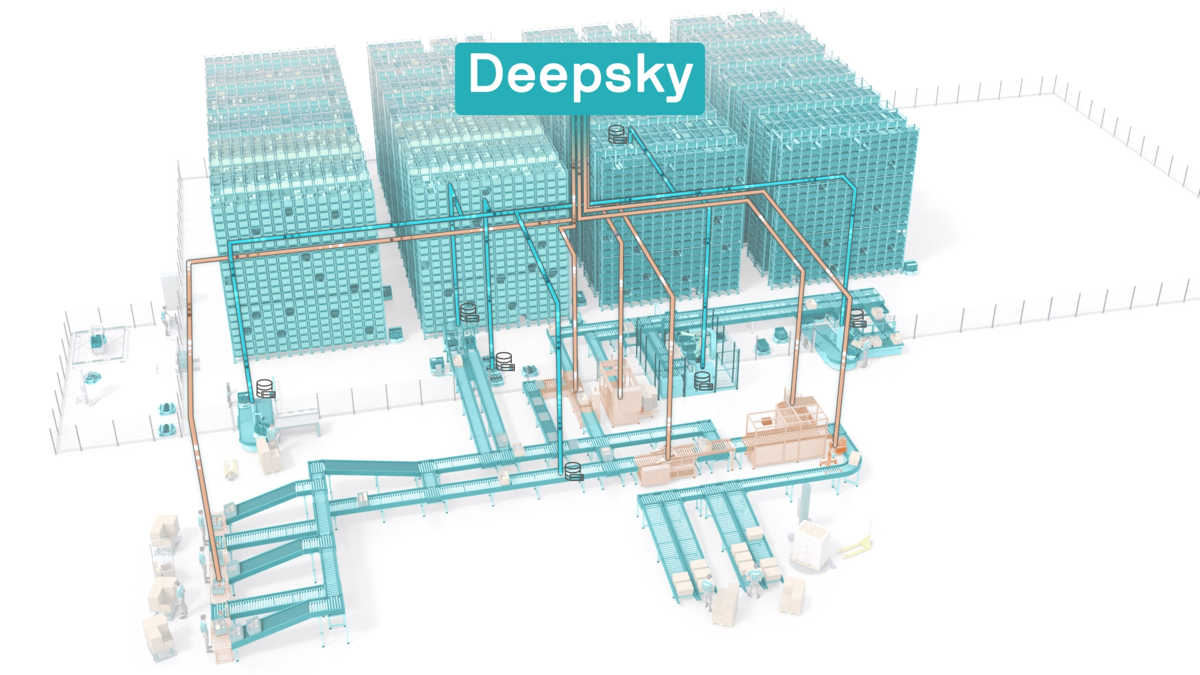

Headquartered in Lille, France, Exotec combines hardware and software to offer warehouse robotic systems that drive operational efficiency, add resiliency, and improve working conditions for warehouse operators. The Skypod System is an order-picking solution for retail, e-commerce, and industrial use. Robots can climb racks up to 12 metres in high and retrieve products autonomously, before delivering totes to human-staffed or automatic picking stations.

Warehouse automation systems like Exotec allow efficient use of height without impacting performance or flexibility. The Skypod System is fully scalable, so storage capacity and picking performance can be increased when required or adapted to the architecture of a warehouse. The system can run continuously throughout the year without impacting performance. In addition, more robots can be quickly added to increase throughput during peak periods. Exotec’s comprehensive software simplifies management of the entire system.

“We selected the Clustag solution by Rielec because we were impressed by its elegant design, proven reliability, and the ability to be delivered quickly by highly competent teams. It perfectly meets our quality and customer satisfaction requirements,” said Chloé Marechal, Supply Chain Manager Western Europe at Exotec.

As part of the partnership, Clustag by Rielec will provide Exotec with its patented RFID MOT Station technology. The MOT Station design provides complete reliability and flow data available to users. The technology can be fully integrated into processes and aggregates three key pieces of data: RFID identification, case volume, and case weight during operation to improve the inventory management process.

The technology can scan the contents of cases with dimensions up to 850 x 650 x 650 millimetres, scanning 400 tags per case at speeds of up to 1,000 cases per hour. The RFID station is UL certified and CE-marked. Used within the fashion industry, the MOT Station combined with Clustag’s ZENTUP software enables retailers to keep pace with fast-moving fashion cycles. Once items are scanned, ZENTUP provides retailers with complete product data, incorporating product types, colours, and sizes to facilitate high-quality stock decision-making, quickly.

ZENTUP will integrate with Exotec’s Warehouse Execution System to provide users with accurate, real-time data. This provides the foundation that enables retailers to deliver efficient and effective order fulfilment for customers.

In the words of Manolo Reguart, Director of Strategy and Business Development at Clustag by Rielec: “RFID technology plays a pivotal role in creating enhanced inventory accuracy within the warehouse. The successful integration of our MOT Stations into some Exotec’s projects will deliver unparalleled inventory visibility for end users”.

With the implementation of Clustag by Rielec technology in Exotec’s warehouse solution, smarter supply chain and order fulfilment decisions can be made that improve sales opportunities and the long-term business success of both brands.

read more