Challenged by poor labour availability, how will fashion fulfilment cope with a return of footfall to the UK high street and growing omni-channel sales? Darcy de Thierry, Managing Director of Ferag UK, believes advanced pouch sorter technology holds the answer.

Successful fashion retailing is all about maximising margin, growing sales volume and getting faster throughput. But for the last two years, omni-channel businesses have, by necessity, had to rely on their ecommerce channels for survival. The strain on fulfilment centres has been enormous, particularly as ‘single’ and ‘few’ item picking and packing operations are traditionally highly labour intensive activities – and labour has become a scarce and costly resource, leading to concerns over performance during critical peak periods.

Now that consumers are returning to the high street, how can businesses re-balance their fulfilment operations to cope with growth and higher throughput across all channels, and at the same time contain costs to maximise margins?

In addition to the challenges of finding labour, the National Living Wage is set to rise from £8.91 to £9.50 per hour in April 2022, coinciding with a hike in National Insurance of 1.25p in the pound for both employers and employees.

With operational costs rising and fewer people available to carry out manual picking operations, many retail fashion businesses are turning to the use of automation to boost the productivity of their labour force. Automation applied to the right processes can free up people for tasks that require human ingenuity, judgement and manual dexterity – tasks such as packing and inspecting returns.

Advanced technology

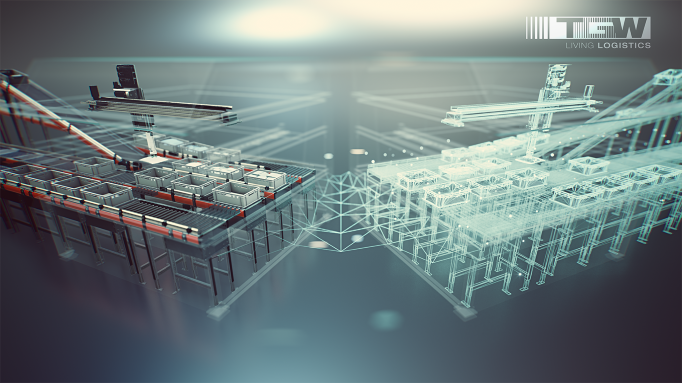

An innovative technology helping to transform operational performance in the fulfilment centre, freeing-up human resources for value-adding activities, is the pouch sorter. Overhead pouch sortation systems offer a flexible and highly scalable, conveying, sorting and dynamic buffering solution appropriate for both fulfilling ecommerce orders and assembling store friendly sequenced replenishment. One pouch system is capable of sorting and processing many thousands of orders an hour, with each pouch able to carry both hanging garments and flat items, such as shoes and flat pack goods, enabling fast order fulfilment from a single pool of inventory.

Creating a single pool of inventory from which store replenishment and ecommerce orders are served offers significant financial and operational benefits. Efficiencies in accessing available stock, greater flexibility in allocating stock to maximise sales and faster processing times for preparing orders, are just some of the key advantages.

In particular, pouch technology lends itself to ecommerce operations, allowing for greater wave picking efficiency, with late order cut-offs of around 10pm for a promise of delivery to the customer first-thing the next day. The speed and reliability of Skyfall, Ferag’s ultra-fast automated pouch sorter solution, enables the retailer to gain greater operational efficiencies by accumulating orders in advance of a final pick-wave at 10pm. With processing speeds of up to 25,000 units per hour orders can be picked, sorted, packed and dispatched within the shortest time window, giving fashion brands the keen competitive edge of a late cut-off with an early next day delivery.

For consumers fast, reliable fulfilment and delivery is often a decisive factor when purchasing a fashion item and a positive experience is likely to result in repeat sales and recommendations on social media. However, a late delivery of a party dress has the potential to cause great distress and may lead to negative reviews, with the loss of future sales, so a reliable fulfilment process is essential. Of course, pick accuracy is important too, as a mispicked item is likely to be disappointing for the customer, as well as costly to the business. However, automation enables exceptionally high pick accuracy.

Store friendly sequencing

As stated earlier, the same high-speed Skyfall pouch sorter system used for fulfilling ecommerce orders can also be deployed to create store friendly sequenced consignments for high-street shops – pulling from the same, pooled inventory. The benefit of sequencing product for a particular store’s layout is that the shop assistant assigned to replenishing shelves and rails is able to perform the task quickly and efficiently, freeing them to spend more time with customers – potentially, to secure more sales.

An obvious advantage of a high-speed pouch solution, such as Ferag’s Skyfall, is that it uses available overhead space – the third dimension of the building – keeping floor areas free for pedestrians and other processes. What’s more, pouch systems are a highly cost-effective alternative to other forms of goods-to-person automation, like multi-shuttle and mini-load solutions, that can cost up to 30% more. Then there is the core benefit that the Skyfall overhead pouch system undertakes high-speed sorting, conveying and buffering processes too, which with Ferag’s modular conveyor technology allows for tremendous flexibility and scalability. And as the pouch has the ability to carry flat items, such as shoes, and flat pack goods along with hanging items, there is no need to have a separate cross-belt sorter for flat items, with all the issues associated with bringing flat and hanging items together.

Leaders in fashion

A number of leading fashion brands are taking advantage of pouch sorter technology to increase capacity and boost performance of their fulfilment operations. Ferag has recently installed a flexible high-speed Skyfall system at a new distribution centre for children’s fashion company, Mayoral Group, in Malaga, Spain. The extensive overhead pouch solution is one of the largest to date, with a mix of hanging pouches and garment hangers totalling more than 58,000 Skyfall hangers, and a throughput of up to 12,000 units per hour. The system features fully automatic unloading of pouches, including flat goods.

Ferag has developed an advanced automated induction process where pouches automatically open at an induction station, the operator scans a product, passes it down a chute and it drops into the awaiting pouch. The process is fast and efficient.

Similarly, Ferag has also introduced auto-unloading technology with three levels of performance depending upon product characteristics and gentle handling requirements. Contingent on the items, between 1500 and 2200 orders per hour can be automatically unloaded from pouches at packing stations. Driving performance, the rate at which orders are presented at the packing station can determine the pace of packing.

Interestingly, when comparing traditional goods-to-person operations, where you may have six to twelve open orders at the packing station, with a pouch system there can be a hundred or more open orders, simply by keeping them in a dynamic buffer near to the packing station. Items can quickly be called from the buffer as required, providing greater flexibility and speed.

Faster returns

When it comes to the fast processing of returns, overhead dynamic buffers can offer a cutting-edge solution to removing the time, cost and effort of placing returned items back into stock. Manually sorting and placing items back into stock is a very time consuming and costly process, but now it can be avoided. For high-demand fashion products, keeping returned items in a buffer close to the packing area enables a quick and efficient re-despatch of the item. In fact, some retailers anticipate and predict levels of returns, allowing them to re-sell items even before they are returned to the warehouse. Such techniques help boost sales and increase margins.

Of course, reliability is absolutely critical for any automated system. Failure to perform at peak or during critical promotional periods can result in unfulfilled SLAs and dissatisfied customers, which in turn may damage both sales and, importantly, brand. Businesses looking to invest in overhead pouch sortation systems should look very carefully at the quality of the engineering, materials and components used. Only ultra-low friction components should be considered and plastic chains should be avoided. Good design and sound engineering bring long-lasting rewards.

Ferag’s Swiss-engineered pouch sorter technology was originally developed for some of the most testing of handling applications, the international print industry, where super-fast overhead conveyors are required to offer ultra-reliable performance on daily newspaper production runs in the millions. The same materials, technology and design expertise has been successfully applied by Ferag within the intralogistics sector, bringing reliable, high-performance conveying at speeds of up to 25,000 units per hour to fashion businesses the world over.