As part of a holistic realignment of its intralogistics, Peterhans Handwerkercenter AG, located at Würenlos near Zurich in the Swiss canton of Aargau, has remodelled and automated the logistics processes of its central warehouse and store for faster order processing and more storage capacity.

After comparing various AKL technologies and solution approaches, the family-owned company, founded in 1952, opted for an AutoStore solution from Element Logic.

“With around 500,000 articles, our multichannel strategy and our continuous growth, we wanted to invest in a system offers close to zero picking errors and maximum flexibility for future system expansions,” said Dieter Egloff, deputy managing director of Peterhans Handwerkercenter AG, explaining the main reasons for the decision. “Therefore, we examined various logistics facilities in practical operation and visited reference facilities with AutoStore solutions. When we weighed up all the factors, it quickly became clear: AutoStore technology was on our wish list. The simplicity of the technology, the flexibility of the storage concept and the output convinced us right from the start.”

Peterhans Handwerkercenter AG distributes building materials, tools, machines, fittings, fasteners and personal protective equipment directly to tradesmen and companies in the construction industry, making it one of the leading companies in this segment in Switzerland. Continuous growth, the servicing of different distribution channels promoted the decision to automate intralogistics.

“We are continuously strengthening our business through future-oriented investments in digitalisation and logistics,” Egloff said. “The automation solution allows us to handle volume increases with the same number of employees.”

The contract for system planning and implementation was awarded to system integrator Element Logic, the first official AutoStore integrator and the world’s most successful AutoStore distributor in 2020. With nearly 200 implemented AutoStore solutions, the company has extensive experience and a competitive edge in the planning, implementation and support of maximally efficient storage and picking systems for container-ready products. Based on this broad foundation, the system integrator is continuously developing further optimisation options in the field of AutoStore technology.

Integration of tailored system

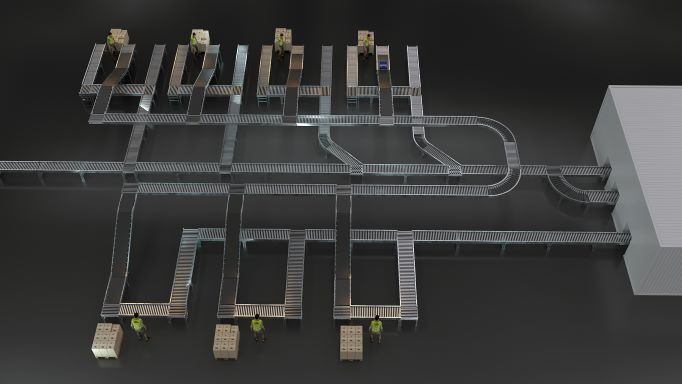

For Peterhans, Element Logic installed an AutoStore system with a footprint of just 400 sq m for around 25,000 storage locations during ongoing operations in a two-stage project.

“The system includes 11,650 totes that are subdivided up to eight high,” said Egloff, illustrating the storage capacity. The 220mm-high bins used allow a load of up to 30kg with internal dimensions of 603 x 403mm.

“The main objectives of the automation project were to improve in-house logistic processes and maximise storage capacity in the existing building by increasing storage density,” said Joachim Kieninger, Director Strategic Business Development Element Logic Germany. “For an optimal layout of the facility, we analysed the very different sales channels and took them into account with regard to layout and processes.”

Peterhans supplies the shelves in the retail store from the central warehouse, orders via the online store, deliveries with its own vehicles to fitters and tradesmen, as well as output for direct pick-ups or orders in the store.”

For these goals, Peterhans and Element Logic already worked closely together in the planning phase. “The result is the perfect integration of an auto store system tailored exactly to our requirements into our existing building,” explained Egloff.

With the AutoStore automated storage and picking solution, the family business opted for an innovative storage concept in which the containers for small parts storage are stacked on top of each other in shafts and stored and retrieved by small robots. The system impresses with its efficiency and flexibility as well as minimal space requirements and comparatively low investment and operating costs.

The container stacks are stored in a standardised aluminium grid up to 5.4m high. The robots work on the surface of this grid. Depending on the container height, up to 16 or 24 bins are stacked on top of each other in a grid. The compact overall system with integrated workstations, the so-called ports, offers 60 to 70% better space utilisation than conventional miniload solutions.

The system layout can be adapted precisely to any structural conditions and is easily scalable with additional robots, ports or shafts to meet growing performance or capacity requirements. Consequently, AutoStore systems achieve the highest storage density among the available miniload solutions. The same applies to energy efficiency: with an average energy consumption of 100W per robot per hour, AutoStore systems have by far the lowest need for energy of all available miniload solutions.

In the system built for Peterhans, 20 bins are stacked on top of each other, adapted to the height of the hall. Ten robots move along the top of the grid. They lift the totes with the desired goods, transfer them to the workstations and stack the totes back into the system after picking.

Special feature: The system was realised in two construction stages due to the fact that it was implemented during ongoing operation. One of the advantages of the modular AutoStore concept, its high flexibility, came to the fore: first, one half of the grid could be conveniently erected, put into full operation and filled with goods. The empty shelving units were then dismantled and the AutoStore system was expanded to include the second half. This solidified the idea of connecting three of the six installed workstations directly to the sales floor.

“Customers are amazed and impressed to see an automated logistics system and transparent processes tied directly to the store,” Egloff said proudly. “This makes us very advanced – and allows us to offer customers something in additional, a unique shopping experience.”

The same applies to energy efficiency: with an average energy requirement of 100W per robot per hour, AutoStore systems have by far the lowest energy consumption of all available miniload solutions. With these attributes, AutoStore solutions form a proven basis for automated processes and fast order processing in modern micro-fulfilment centres, for example in online retailing.

97% fill rate

The workstation modules used in the AutoStore system are so-called carousel ports for higher warehouse throughputs and conveyor ports for lower throughputs. The carousel ports serve both as picking and repacking stations for loading the system totes.

Of the six ports at Peterhans, the three conveyor ports on the sales floor are used to retrieve goods for store customers. The three ports that are not visible in the store are used for retrieval of dispatching orders from the online store and for external deliveries to companies and fitters in the field, for example.

“In less than two minutes, a customer’s order is at the sales counter,” Egloff pointed out. “The system control of the AutoStore system knows which bin is in which place, calculates the routes and then distributes the driving orders to the robots via radio link.”

The robots work in a coordinated manner, quickly rearranging the totes, quickly releasing the required bins and filling them into the shafts for the integrated workstation modules. Thereby the system automatically ensures that the bins are positioned according to ABC criteria: Less frequently requested containers slide successively further down, while fast-moving items remain continuously in quick access on the upper levels.

“Compact, high-density storage and fast, virtually error-free picking,” summarised Egloff. “With a system filling level of 97%, an average of 15,000 picks are made with the system per month – between 700 and 800 accesses per day.”

Immediately after installation, Element Logic’s AutoStore solution enabled the company to meet customer expectations for same-day delivery and shorter waiting times at in-store pickup counters. And the AutoStore system is also a great benefit for employees: “Our new, fully automated AutoStore system simplifies important loading processes and significantly supports our employees in their daily work. They no longer have to cover long distances or lift heavy goods. Overall, the picking processes are less labour-intensive for them than before.”

Element Logic ensures high system availability through its service team with preventive maintenance on site, as well as qualified telephone and online support.

According to Peterhans’ calculations, the investment in the AutoStore system will be paid off in five years. The flexibility of the storage system supported the two-stage project creation during ongoing operations as well as future growth.

“Without the AutoStore system, we would have had higher staffing requirements in logistics,” said Egloff. “With the AutoStore facility, we were able to meet the steady growth and even the rapid increase in online orders, because the retail store remained closed during the pandemic, without additional resources. An investment in the future from the very beginning. We can now count on a high-performance, automated small parts warehouse and our partner to meet our customers’ expectations for fast order fulfilment.

“And the system is still standing so well because we had such a good implementation partner in Element Logic. We are completely satisfied with the project handling, the cooperation and the results.”

The project details at a glance:

- 400 sq m AutoStore plant footprint

- 11,650 bins with around 25,000 storage locations

- 10 robots

- 6 ports

- Simplified and ergonomic warehouse processes

- Increased efficiency through automation

- Important component of the digital transformation

- Nearly zero defect picking

- Same-day order processing and delivery

- 80% Space savings offer future expansion potential

- Highly reliable plant technology

- Reduced burden on employees

CLICK HERE to watch a video of the project