Swedish hair and beauty specialist Lyko has chosen Vanderlande to automate its new warehouse in Vansbro, Sweden. The two companies signed a contract for the installation of Vanderlande’s FASTPICK goods-to-person (GtP) order fulfilment system, including robotic item picking. Lyko needs a new solution to cope with rapid growth and to meet its ambition to break into emerging European markets.

Vanderlande’s FASTPICK was selected because it meets the company’s need for greater efficiency and capacity, and can be installed on a limited footprint. The greenfield warehouse is scheduled to open in 2025 and will be Lyko’s largest automation project so far. The scalability and flexibility of Vanderlande’s solution provide the opportunity for further extension.

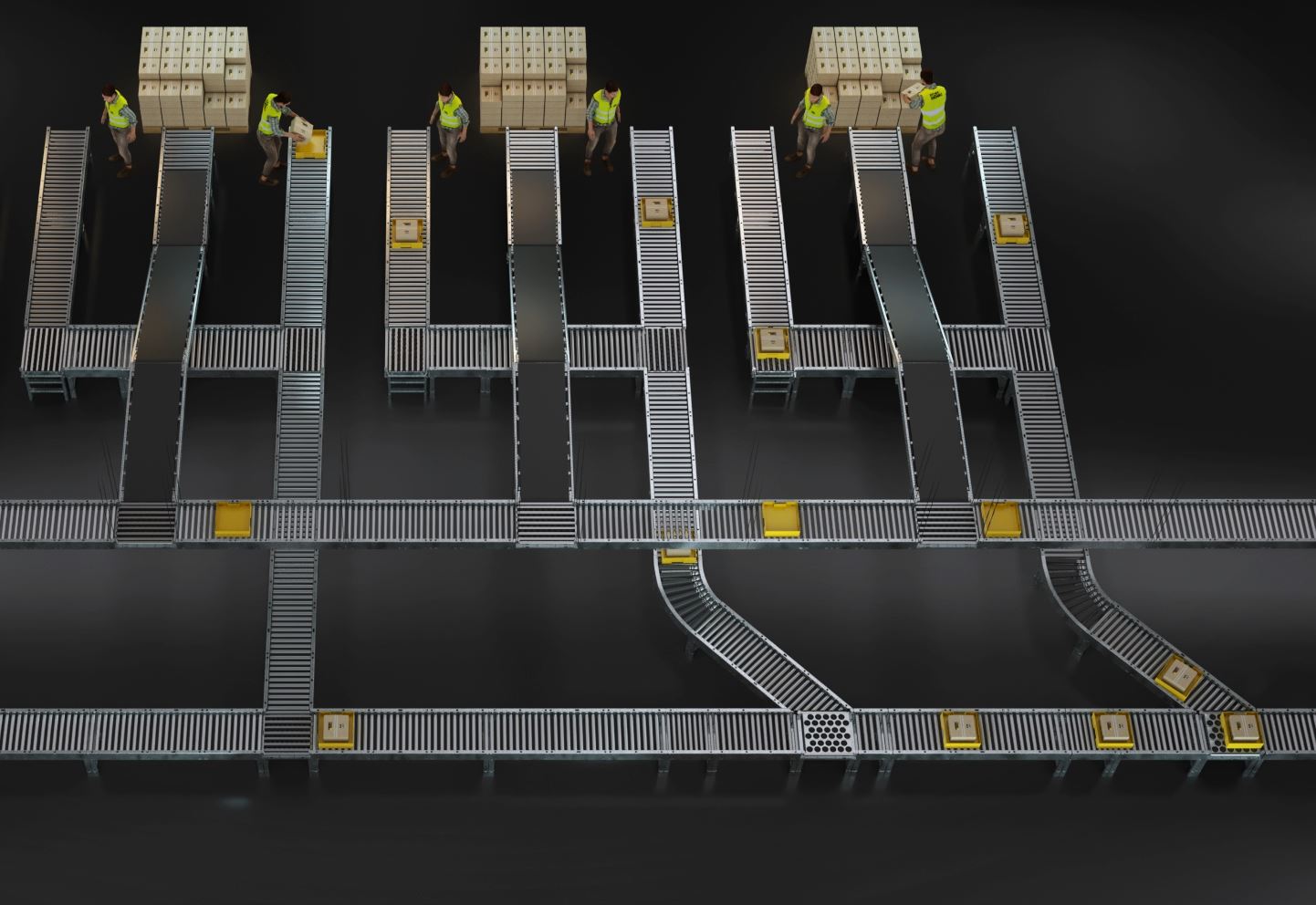

The system includes the ADAPTO automated storage and retrieval system (AS/RS): 216 ADAPTO shuttles will be able to access more than 152,000 product locations across 27 levels and 40 aisles. The innovative system will be capable of handling 45,000 orders every day. The contract also includes 15 GtP workstations, three of which are equipped with robot item pickers from Vanderlande’s portfolio of Smart Item Robotics. In addition, all the manual workstations, including those for decanting, are height adjustable to minimise lifting duties for operators. The system also includes Vanderlande’s POSISORTER shipping sorter.

The state-of-the-art solution is driven by Vanderlande’s digital suite of software services. During the entire process, the system handles items as gently as possible, which makes it an ideal solution for Lyko, with its stock of fragile and expensive products, such as bottles of perfume.

“This solution gives us the capabilities we need to scale our business in a cost-efficient way – it will therefore support our plans for growth and help us expand into Europe,” says Rickard Lyko, Lyko’s CEO and founder. “By increasing our capacity and providing us with the efficiency we need through integrated robot technology, Vanderlande has shown that it best understands our needs.”

“We listened closely to what the Lyko project team needed, and we’re delighted that they chose our state-of-the-art technology to help realise their expansion plans,” says Vanderlande’s Executive

Managing Director Warehouse Solutions, James Cotton. “The FASTPICK solution offers the company the flexibility and sophistication it requires to handle an extensive range of products and deliver orders to customers as quickly as possible. We look forward to the installation and forging a long-term partnership with this dynamic company.”