stow Group, a globally recognized leader in the design, manufacturing, and implementation of advanced storage solutions and automated warehouse systems, announces the launch of the new ‘Movu Robotics’ brand, developed to strengthen its Robotics business unit and to meet increasing customer demand for Automation and Robotics solutions. The new brand replaces the name ‘stow Robotics’ as of now.

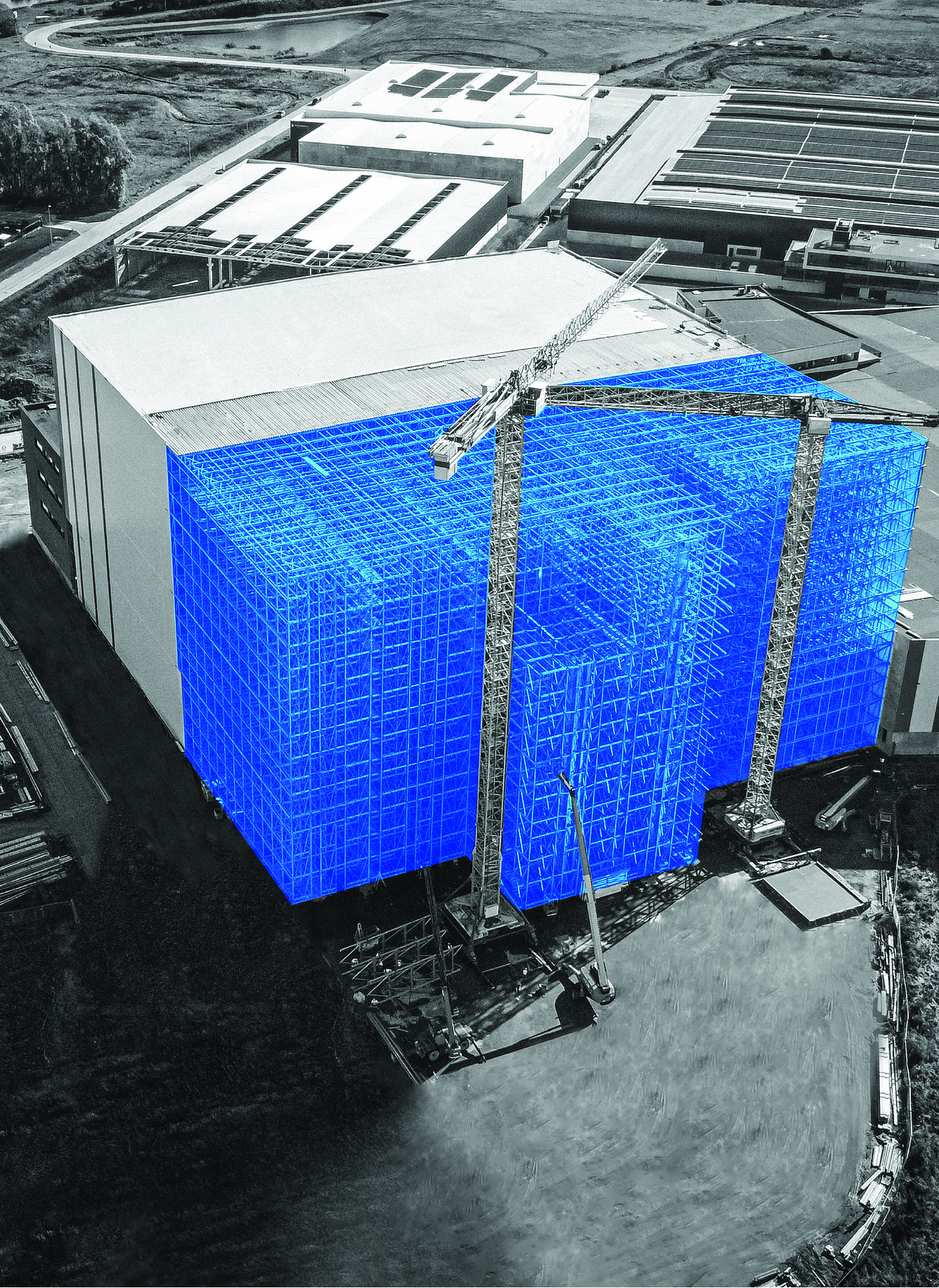

Movu Robotics is a new and dynamic warehouse automation brand that stands out by bringing easier logistics automation solutions to the world’s warehouses and ensuring that, when it comes to opportunities for automation, no warehouse is left behind. Movu is based in new headquarters located in Lokeren, near Antwerp in Belgium that, under a single roof, includes engineering, R&D, production, and a state of the art Experience Centre where the latest technologies can be demonstrated live in operation to customers and partners.

stow Group is a highly successful company with 40 years’ experience as a supplier of logistics and materials handling solutions , and a product DNA based on racking. As customer and market demand for automated solutions increase s driven by labour shortages, the need to increase profitability, efficiency, flexibility, accuracy as well as shortening lead times stow has been delivering innovative solutions to meet these challenges.

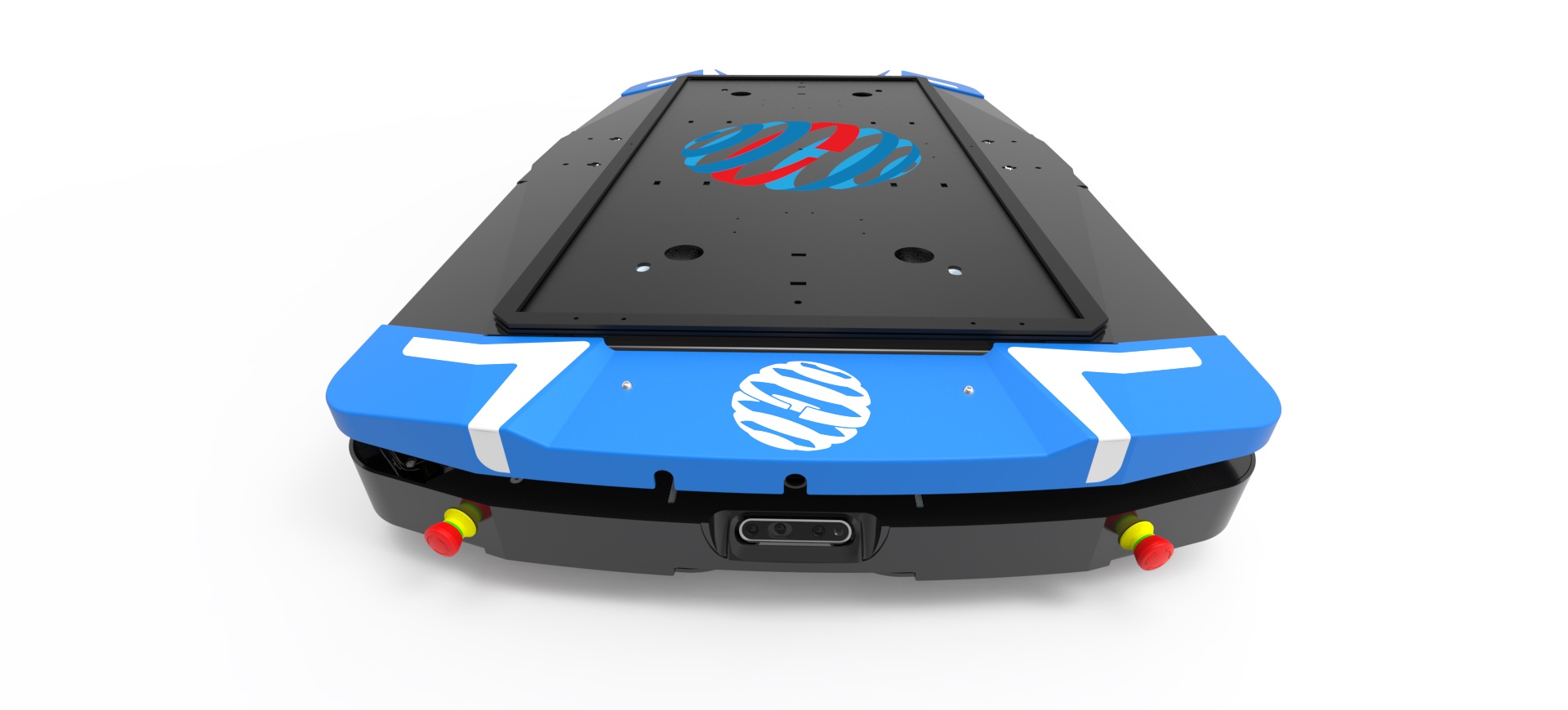

stow Robotics was e stablished in 2021 a s part of the stow Group and has developed a comprehensive and competitive portfolio of automation and robotics solutions for pallets, bins and items that provides a more energy efficient and practical alternative to stacker crane bins and items that provides a more energy efficient and practical alternative to stacker crane based solutions-based solutions. This comprises Movu atlas, a leading pallet shuttle system; Movu escala, an innovative ramp shuttle solution for totes/bins; Movu ifollow, a collaborative Autonomous Mobile Robot (AMR) system for pallets and additional load carriers: and the new picking robot Movu eligo.

Despite all their advantages, automated technologies and robotics are perceived by many customers as being complex, expensive, resource intensive with long lead time for installation. Movu Robotics addresses this issue by bringing easier automation to the world’s warehouses.

Movu – No warehouse left behind

For projects in the main vertical markets, especially in e-commerce, FMCG and cold storage in Europe and North America, Movu Robotics will deliver simple, standardised plug and play solutions that require less engineering and grant short lead times for execution, allowing customers to keep their operations running.

Jos de Vuyst, CEO of stow Group told Logistics Business: “Faced with challenges of labour shortages, cost increases, storage density, growing volumes and improving accuracy, companies are turning to robotics and automation for solutions. Movu Robotics offers an offers an integrated ecosystem of standardised and scalable automation technology that speeds roll out and reduces risk for all for all kinds of customers. We want to democratise materials handling through bringing the opportunities of easier automation and robotics to warehouses that would otherwise find them hard to attain. Expecting the global material handling equipment market to reach USD 350 billion and understanding the key driver AS/RS systems and Robotics systems for this, we are optimistic that Movu Robotics will become an essential player.”

Stefan Pieters, CEO of Movu Robotics, commented: “Smart enough to make any operation feel simple and easy, Movu robots help to take a load off the customers’ minds as well as their shelves. Our solutions are designed to make warehouse automation and robotics not only more accessible, but also more scalable. They will enable any warehouse around the world – big or small, regular or awkwardly shaped – to be upgraded and become more productive, more efficient and more successful. This is the philosophy behind our brand claim: ‘’Movu – No warehouse left behind’.”

Group structure

stow Group now has two independent brands under its roof: stow Racking and Movu Robotics. While both of these brands retain their independence, they strongly impact each other in terms of expertise, know how, technology and global resources. All products, business activities and operations of stow Group in the field of Robotics and Automation, including R&D, production, sales and finance, will be grouped as an independent and standalone business unit under the Movu Robotics brand in the new headquarters in Lokeren. This includes the operations of the ifollow business, which is now the brand name of AMRs offered by Movu.

The management team will be led by Jos de Vuyst, CEO of stow Group and Stefan Pieters, CEO of Movu Robotics. Both stow Group and Movu Robotics are driven by a strong a strong team of board members, comprising experience from the Logistics Industry and from other sectors.

Movu Robotics technologies

Unlike many automation companies that have a single product, the new Movu Robotics brand includes a range of key technologies: Movu atlas pallet shuttles, Movu escala bin shuttles and Movu ifollow AMRs for pallets and roll cages that work either standalone or as collaborative robots. Joining these is the new Movu eligo picking robot, which is offered as a picking workstation for escala.

Movu Robotics provides solutions for easier automation that can make better use of every corner of the warehouse – irrespective of the customers’ storage space or what they are storing, conveying, picking or handling. Customers gain the key advantage of seamless integrated racking and robotics solutions – for example, the Movu atlas shuttle system working with Movu ifollow mobile robots, or Movu eligo acting as a workstation for Movu escala. A key benefit is that a customer talks to a single face representing a single partner, providing efficient project management and reliable lead times. They will also receive efficient project commissioning for a safe and resilient supply chain that assists in delivering high service levels to their customers.

Autonomous sub–systems for minimal TCO

Technologies in the Movu Robotics product portfolio can be integrated into a single autonomous sub-system as a solution, with components including racking, shuttles or AMRs, software, wifi and commissioning. This enables easy installation, adaptability to new business needs through simple integration of new applications and a minimal Total Cost of Ownership (TCO) approach. This makes upgrading warehouses easier, not only for existing users of logistics automation who want to upgrade their systems with plug and play robotics and automation, but also those yet to adopt automation but who urgently want to take the first step.

Standardisation and simplification, which is an essential part of Movu Robotics, results in shorter lead times and lower engineering costs, producing higher profitability. To maximise flexibility, Movu Robotics systems are modular in design, acting as a set of building blocks to minimise complexity and cost of upgrading. This makes the systems highly scalable – installations can start small and then expand or, if needed, they can downsize just as easily. Modularity also enables a fast roll out for projects.

For not leaving any warehouse warehouse behind, Movu Robotics will target the market with a dual strategy: providing end users with a direct channel, for which Movu relies on a network of sales offices in main territories. Its portfolio of simple, standardised, scalable, and flexible systems provide opportunities for SMEs with as few as 5000 pallet locations to automate, to address challenges such as labour shortages and cost efficiency -– a huge growth area. The other part of this strategy is the indirect channel where Movu can supply a fully functional storage sub-system from its portfolio to a systems integrator for integration into a complete project. All of this is supported by a global network in customer service and stow’s 40 years’ industry experience.

Movu Robotics is consistently working to improve existing technology for the customer, with innovation, R&D and entrepreneurial thinking being an integral part of the dynamic business unit. The next product launch is planned for 2024, to further expand the portfolio.

Movu Robotics’ headquarters in Lokeren, Belgium, combines a 5,000 square metre large office area with a 10,000 square metre surface for logistics and manufacturing operations under a single roof, next to a state-of-the-art experience centre – one of the biggest in Europe — where where the latest technologies are showcased live to customers and partners.