Simulation modelling, the process of creating and analysing digital prototypes of existing and proposed systems to predict their performance in the real world, has become one of operational research’s most important fields. The tools that simulation modelling provides both in engineering and business disciplines can reap abundant benefits for any organisation that utilise them.

Some of these benefits include:

- Shorter design and development cycles with the ability to modify and re-test a model without the need to spend time and money building and testing multiple prototype iterations.

- A virtual platform for creating realistic test scenarios. Other types of prototypes are not always practical for testing all possible operating conditions. With simulation, there are no ‘physical limits’ to the operational scenarios that can be modelled and tested.

Simulation modelling has advantages over more traditional approaches, such as mathematical forecasting, and optimisation. These approaches are more ‘theoretical’ and often-based on mathematical assumptions and constants about how an object and/or process will behave. With simulation, you do not need to make as many assumptions – with an accurate model design and the right simulation software, you can try different scenarios and know exactly what the behaviours of objects and processes might be.

Simulation modelling software is available in many forms. Some utilise spreadsheet scripts linked with relational databases and automations, which are regarded as the simplest and most universally used general purpose simulators. Whilst others provide more explicit discrete event simulation, with process-centric elements that model the transactions and flows within systems.

Additionally, some offer agent-based simulation or systems dynamics approaches, and only one, as far as we are aware, provides its users with a ‘hybrid’ multimethod approach for creating realistic and insightful scenarios. Multimethod modelling environments which ‘package’ discrete event, agent-based and system dynamics approaches can be used to simulate systems of greater complexity and at different granularities, more simply.

AnyLogic, a simulation package, serviced by DSE Consulting in the UK and Italy, is regarded as being the first tool to introduce multimethod simulation modelling. No doubt its competitors will follow with similar approaches, but for now, AnyLogic retains the pole position in its field.

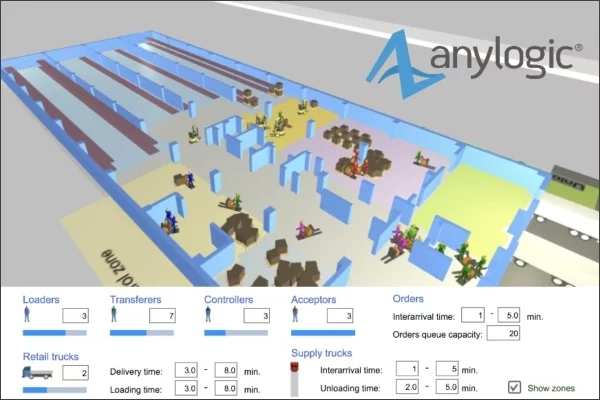

AnyLogic provides its users with various visual modelling compatibilities that are embodied in process flowcharts, state charts, action charts, and stock & flow diagrams. It also provides animation and visualisation facilities too. Such capabilities are augmented by the fact that it can draw from extensive sets of 2D and 3D graphical objects to visualise vehicles, staff, equipment, buildings, and other items and processes related to business.

Moreover, it can convert a model’s logic and metrics into interactive dashboards, capturing your key performance indicators in an and integral way with CAD layouts and GIS maps within its outputs. These graphical features have been found to be particularly useful for engaging and informing stakeholders when simulation projects they add a positive ‘feel’ to the simulations which inspire confidence in the end results.

Additionally, AnyLogic uses an extensible Java IDE that allows users to import custom 3D models, icons, drawings, and other geometric and operational data files into its modelling environment. There is also an existing set of industry-specific libraries, which act as verticals for a range of business processes and workflows to make modelling extremely rapid.

Software today would not be attractive unless it has a cloud component. AnyLogic has a range of cloud capabilities from subscriptions to local server-based, which position it for use on a range of platforms from the desktop to fully portables phones and tablets. Its private cloud infrastructure can be integrated into company workflows so that the models it outputs can be deployed virtually, anywhere.

DSE Consulting experience healthy sales of its multimethod simulation package and have caught the industry’s eye for innovation. It was recognised by the Midland Enterprise Board in 2020, as ‘best International software reselling business in the UK,’ in its field. The award was given for its help to organisations management teams and business leaders in solving the latest data analytics problems.

In 2021 the company became a headline sponsor for The OR Society’s Simulation Workshop, an event which celebrated the latest simulation and modelling breakthroughs, internationally, across industry and academia.

We can see that late shipments started to grow during the week of 4th July, and reached their peak during the week of 11th July, registering growth of 18% and 15% over the previous week for Belgium and Germany. Late shipment trends in the Netherlands have been more stable compared to other two countries.

We can see that late shipments started to grow during the week of 4th July, and reached their peak during the week of 11th July, registering growth of 18% and 15% over the previous week for Belgium and Germany. Late shipment trends in the Netherlands have been more stable compared to other two countries.