Dexory, a leading provider of cutting-edge AI and robotics solutions announced the first deployment of its robotics and artificial intelligence solution in the United States. Dexory’s technology is now in use at one of DB Schenker’s significant sites in Utah. This follows Dexory’s strategic expansion announcement into the North American market in early February.

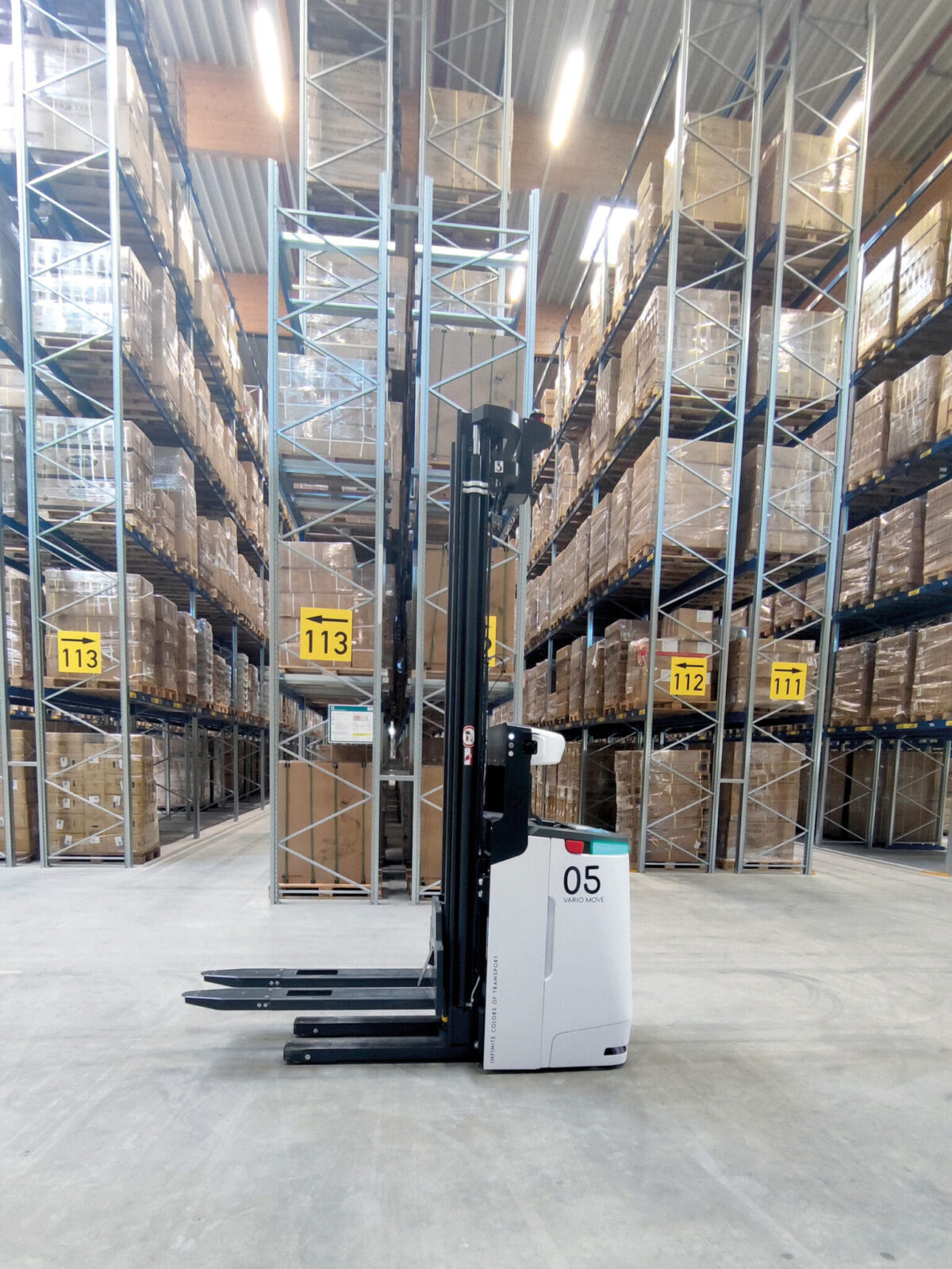

In a swift and efficient implementation, Dexory unveiled its cutting-edge DexoryView solution, featuring state-of-the-art autonomous mobile robotics (AMRs) and a seamlessly integrated digital twin. The rapid deployment has resulted in the generation of real-time data points, providing DB Schenker with immediate insights into its operations.

DB Schenker, a global leader in logistics and supply chain management, is to leverage Dexory’s technology to enhance its real-time visibility of stock and occupancy tracking capabilities. With a focus on promoting efficiency and optimizing resource utilisation, the DexoryView solution scans the Very Narrow Aisle (VNA) area of the site, covering a staggering 40,000 pallet locations daily.

Leveraging advanced computer vision and AI, DexoryView provides clear, visual insights for every shelf and height level. This eliminates the need for manually checking discrepancies and ensures important operational information is easily accessible. It emphasizes priority actions, helping to make operations more efficient.

Daniel Spencer, Director – Solutions & Engineering at DB Schenker Americas comments “We are excited to introduce Dexory’s promising technology in our warehouses. The deployment of Dexory’s robotics and AI solution underscores our dedication to staying at the forefront of technological advancements and highlights our pursuit of operational excellence.”

Digital Twin

The collaboration between Dexory and DB Schenker teams has been instrumental in ensuring a comprehensive success of the integration and utilization of the DexoryView solution. Working in tandem, both teams are committed to maximizing the potential of the collected data, enabling the effective deployment of robotics and AI in the logistics and supply chain industry.

“This live deployment signifies a major step forward in Dexory’s mission to revolutionise how businesses approach logistics and operational efficiency. The progress achieved with DB Schenker serves as a testament to the power of innovative technology in transforming traditional practices, ushering in a new era of precision, speed, and insight in the world of logistics”, says Oana Jinga, Chief Commercial & Product Officer at Dexory.

Dexory looks forward to further collaborations and deployments that will continue to redefine industry standards and drive operational excellence. To find out more for yourself, Dexory will be exhibiting at MODEX in Atlanta from March 11-14 alongside representatives of DB Schenker at booth #B708.

read more